Preparation method of a superhydrophobic anti-corrosion self-assembled three-dimensional nanomaterial

A three-dimensional nano, self-assembly technology, applied in the direction of anti-corrosion coatings, bulk chemical production, coatings, etc., can solve problems affecting reduction performance and achieve excellent reduction activity, improve permeability resistance, and increase fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

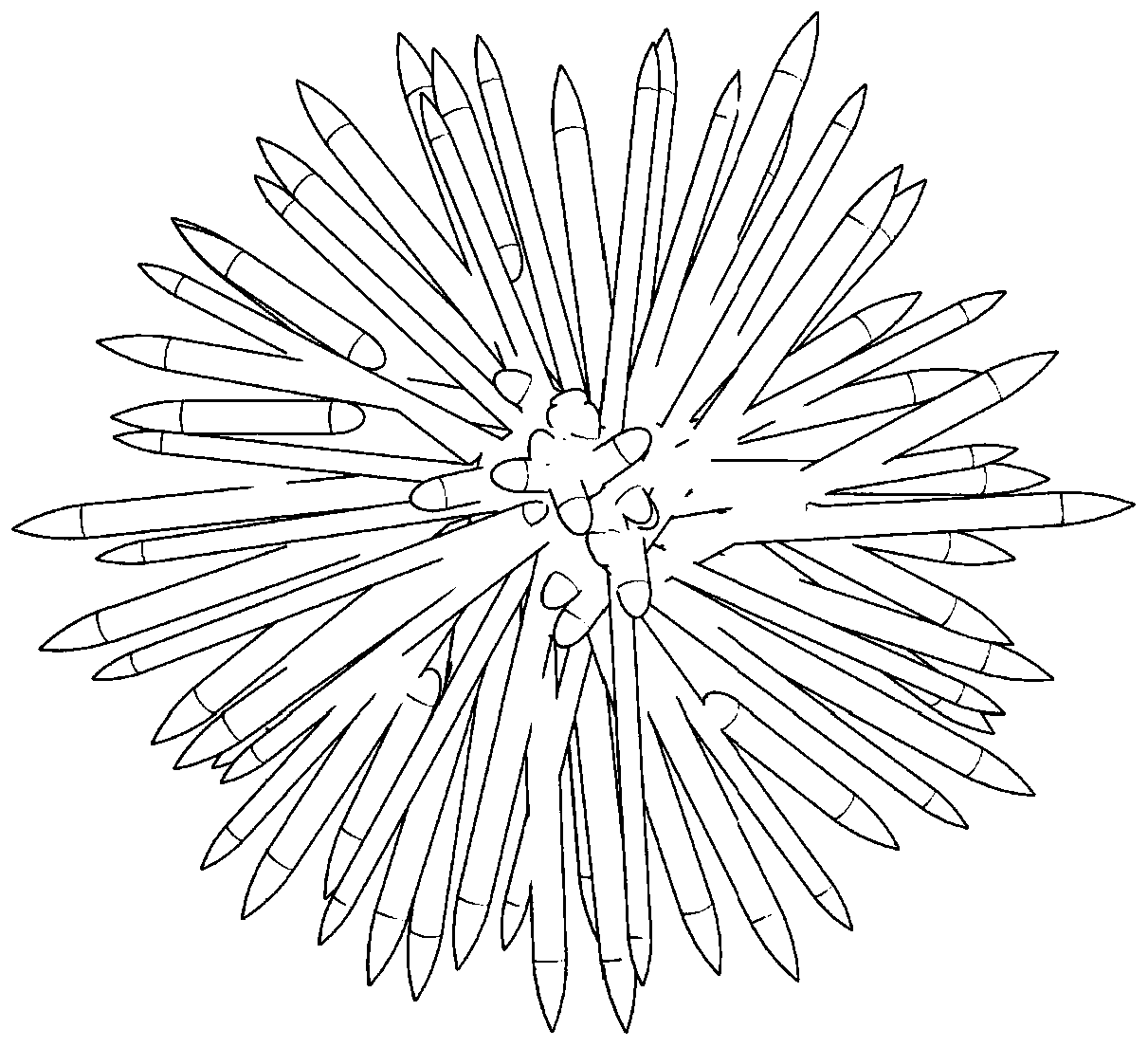

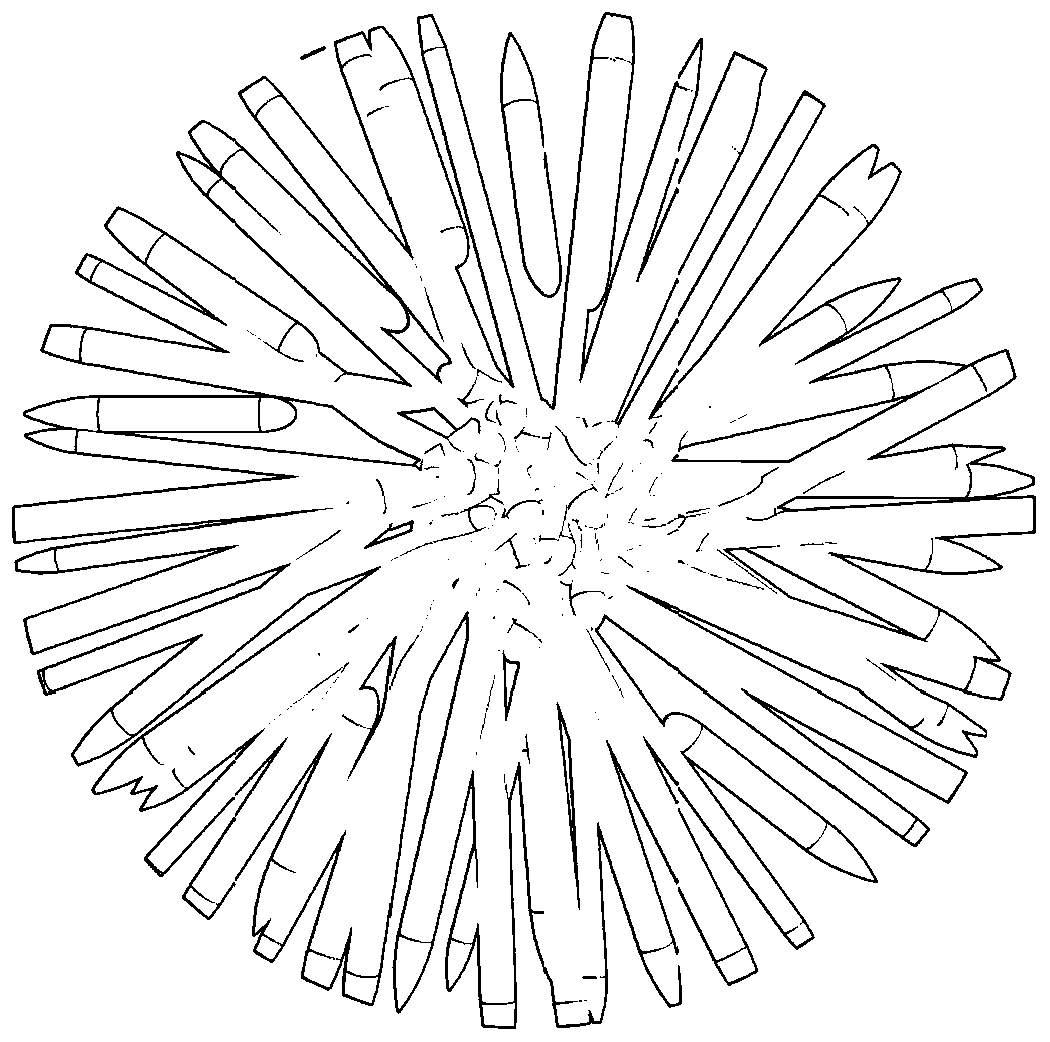

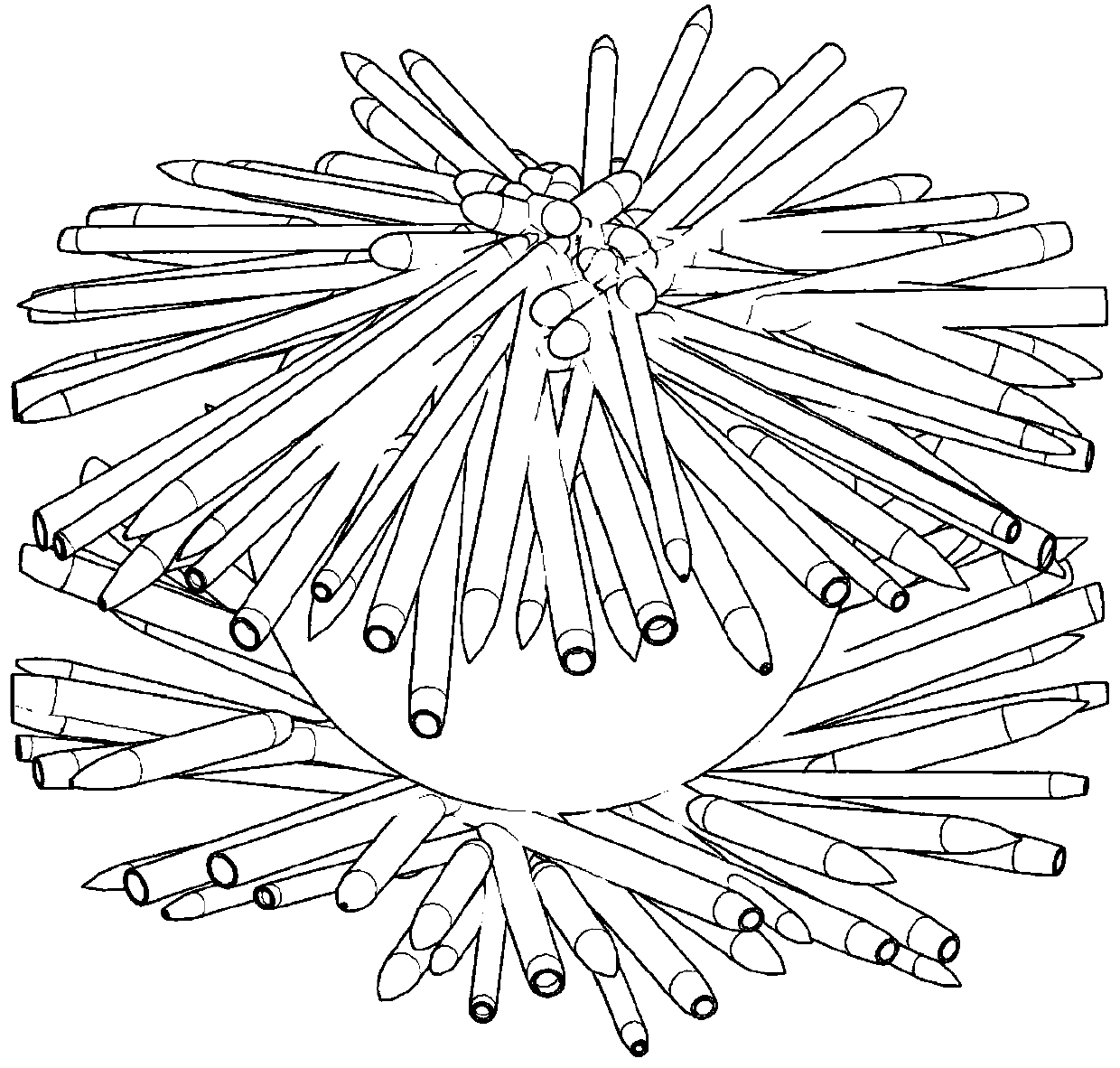

[0020] The arc discharge method uses a graphite rod as the anode, the deposition atmosphere is 50kPa argon, and the DC arc discharge current is 120A; figure 1 As shown, the prepared "Dahlia-shaped" carbon nanohorn particle size is 80nm. The carbon nanohorns prepared above were subjected to instantaneous oxidation treatment, the oxidation atmosphere was 80kPa oxygen, the oxidation temperature was 800°C, and the oxidation time was 5min; figure 2 As shown, the prepared open-pore carbon nanohorn particle size is 70nm. Prepare carbon nanohorn-nano zinc mixed ethanol slurry, wherein the solid content of carbon nanohorn is 1%, the solid content of nano zinc is 0.5%, and the particle size of nano zinc is 50nm. The above mixed ethanol slurry is subjected to supercritical fluid treatment at a temperature of 300 °C, a pressure of 8 MPa, and a treatment time of 1 h; image 3 As shown, the particle size of the prepared carbon nanohorn-nano-zinc composite material is 80nm.

Embodiment 2

[0022] The arc discharge method uses a graphite rod as the anode, the deposition atmosphere is 70kPa argon, and the DC arc discharge current is 200A; the obtained "Dahlia-shaped" carbon nanohorns have a particle size of 100nm. The carbon nanohorns prepared above were subjected to instantaneous oxidation treatment, the oxidation atmosphere was 100 kPa oxygen, the oxidation temperature was 900° C., and the oxidation time was 5 minutes; the particle size of the prepared open-pore carbon nanohorns was 80 nm. Prepare carbon nanohorn-nano zinc mixed ethanol slurry, wherein the solid content of carbon nanohorn is 3%, the solid content of nano zinc is 2%, and the particle size of nano zinc is 50nm. The mixed ethanol slurry was subjected to supercritical fluid treatment at a temperature of 350° C., a pressure of 35 MPa, and a treatment time of 5 hours; the particle size of the prepared carbon nanohorn-nano-zinc composite material was 100 nm.

Embodiment 3

[0024] The arc discharge method uses a graphite rod as the anode, the deposition atmosphere is 70kPa nitrogen, and the DC arc discharge current is 200A; the obtained "Dahlia-shaped" carbon nanohorns have a particle size of 100nm. The carbon nanohorns prepared above were subjected to instantaneous oxidation treatment, the oxidation atmosphere was 100 kPa oxygen, the oxidation temperature was 850° C., and the oxidation time was 5 minutes; the particle size of the prepared open-pore carbon nanohorns was 80 nm. Prepare carbon nanohorn-nano zinc mixed ethanol slurry, wherein the solid content of carbon nanohorn is 3%, the solid content of nano zinc is 1%, and the particle size of nano zinc is 50nm. The above mixed ethanol slurry was subjected to supercritical fluid treatment at a temperature of 270° C., a pressure of 12 MPa, and a treatment time of 2.5 hours; the particle size of the prepared carbon nanohorn-nano-zinc composite material was 100 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com