Dyeing technology of heavy twisting polyester fabrics

A polyester fabric and process technology, which is applied in the field of textile processing, can solve the problems of poor coloring rate, difficult dyeing of dyes, low dyeing rate of strongly twisted polyester cloth, etc., and achieves the effect of improving the dyeing rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

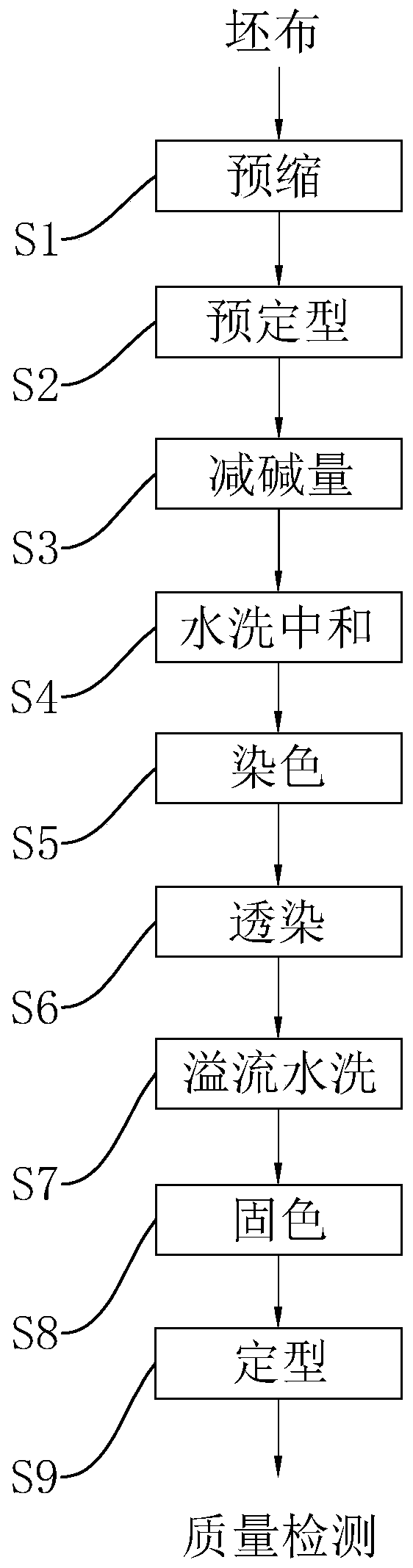

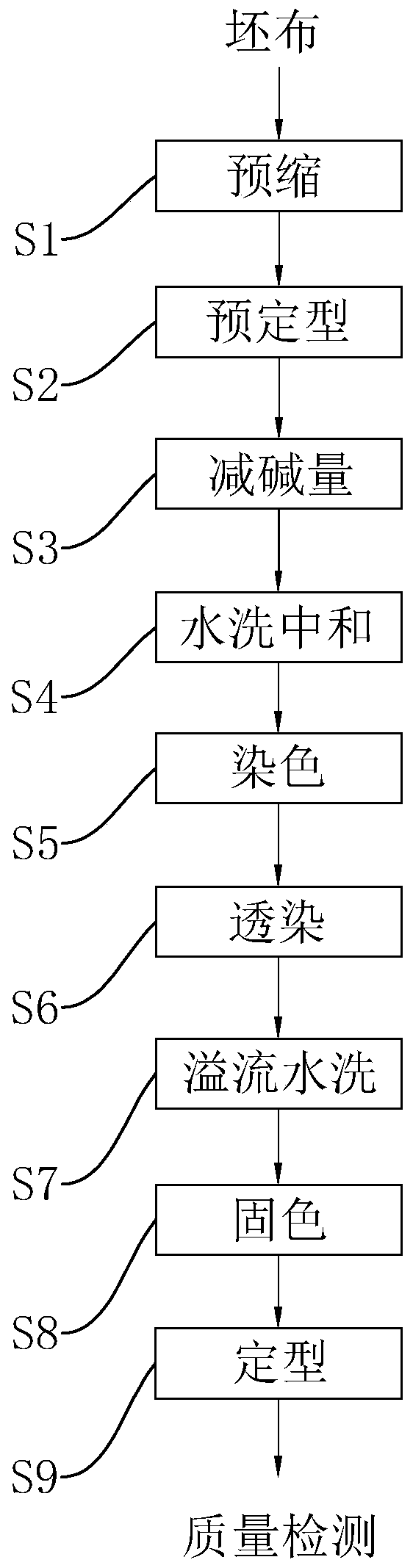

[0046] refer to figure 1 , a dyeing process of strong-twisted polyester cloth, the selected strong-twisted polyester gray cloth (hereinafter referred to as gray cloth) is processed in the following steps:

[0047] S1: Preshrink the gray fabric to be dyed. Place the gray cloth in the high temperature and high pressure overflow dyeing machine, and then add sodium hydroxide solution in the high temperature and high pressure overflow dyeing machine for pre-shrinking treatment. The concentration of sodium hydroxide is 4-6g / L, and the temperature is controlled at 110°C. The time is 40 minutes. Wash twice after shrinking.

[0048] S2: Presetting the gray cloth after S1 treatment. Put the gray cloth into the heat-setting machine, adjust the temperature in the heat-setting machine to 180°C for 5 minutes, and then wait for the gray cloth to cool to room temperature (25°C).

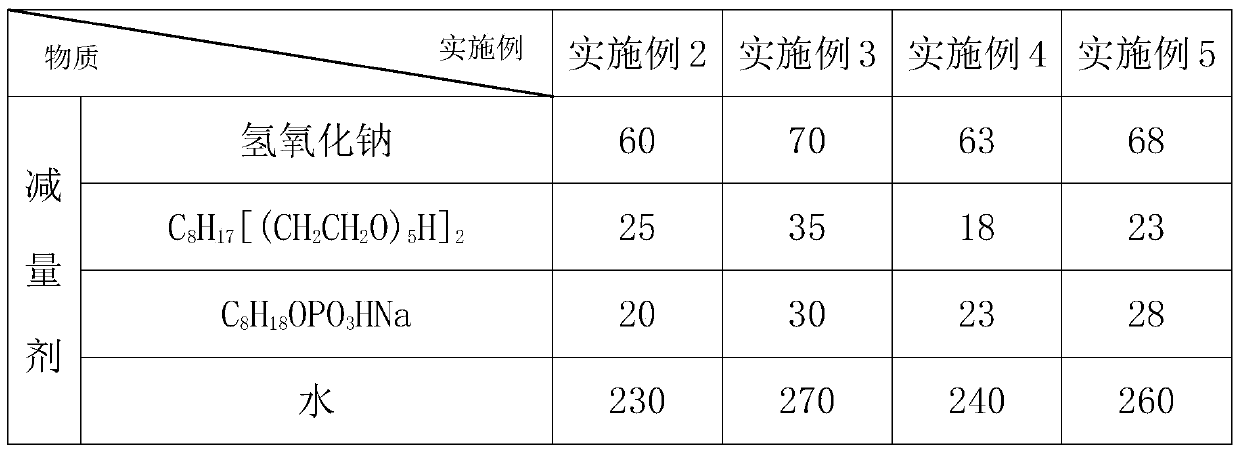

[0049] S3: reducing the amount of alkali on the gray cloth after S2 treatment. The gray cloth is put into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com