Coated paper and preparation method thereof

A technology of coated paper and coating liquid, applied in the field of quantum dots, which can solve the problems of complex process of quantum dot anti-counterfeiting paper and low utilization rate of quantum dots, and achieve remarkable anti-counterfeiting effect, simple anti-counterfeiting effect and good printing suitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

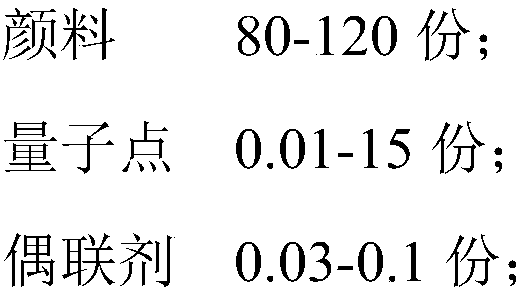

[0023] An embodiment of the present invention also provides a method for preparing the above-mentioned coated paper, comprising the following steps:

[0024] S01: Provide base paper, prepare a coating solution, and the coating solution contains pigments, quantum dots, coupling agents, and adhesives;

[0025] S02: apply the coating liquid on the surface of the base paper and perform drying treatment to form a coating layer to obtain the coated paper.

[0026] The preparation method of the coated paper provided by the embodiment of the present invention has a simple process, is a low-cost, suitable for mass production of a coating paper preparation process with anti-counterfeiting properties. Coated paper with anti-counterfeiting properties.

[0027] Further, in the above-mentioned step S01: the acquisition of the base paper is very conventional, and the base paper can be purchased or obtained by papermaking according to a specific production process. The specific papermaking p...

Embodiment 1

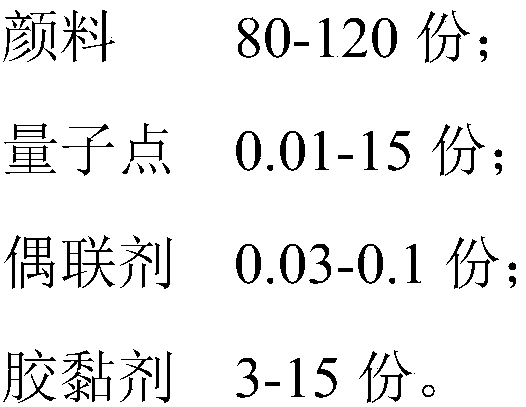

[0039] A kind of coated paper, comprises base paper, and one side of described base paper has coating layer, and described coating layer is made of the coating solution that contains the following components by weight:

[0040]

[0041] The preparation method of this coated paper comprises the steps:

[0042] S11: providing base paper and preparing the coating solution;

[0043] S12: Coating the coating solution on the surface of the base paper for drying treatment to form a coating layer to obtain the coated paper; wherein, the coating amount of the coating solution is 5-60 g / m 2 , the temperature of the drying treatment is 80-170° C., and the time is 5-20 minutes.

Embodiment 2

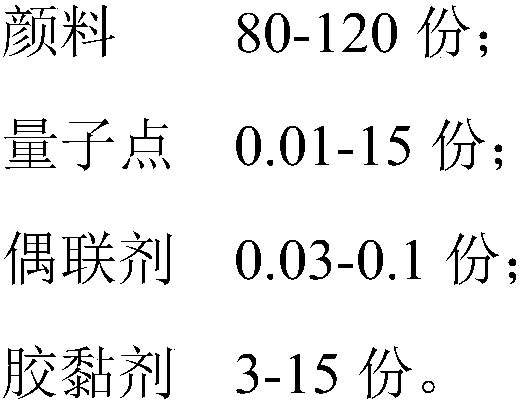

[0045] A kind of coated paper, comprises base paper, and one side of described base paper has coating layer, and described coating layer is made of the coating solution that contains the following components by weight:

[0046]

[0047] The preparation method of this coated paper comprises the steps:

[0048] S21: providing base paper and preparing the coating solution;

[0049] S22: apply the coating liquid on the surface of the base paper and perform drying treatment to form a coating layer to obtain the coated paper; wherein, the coating amount of the coating liquid is 5-60 g / m 2 , the temperature of the drying treatment is 80-170° C., and the time is 5-20 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com