Clamping nail of heat preservation board

A technology of board clip nails and backing plates, which is applied in the directions of thermal insulation, building components, construction, etc., can solve the problem that the EPS thermal insulation board of the grid frame cannot be fixed, and the thickness of the EPS thermal insulation board of the grid frame and the protective layer of the shear wall steel bar cannot be guaranteed. The problem of large damage to the grid EPS insulation board can improve stability and position accuracy, improve construction efficiency, and prevent dumping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

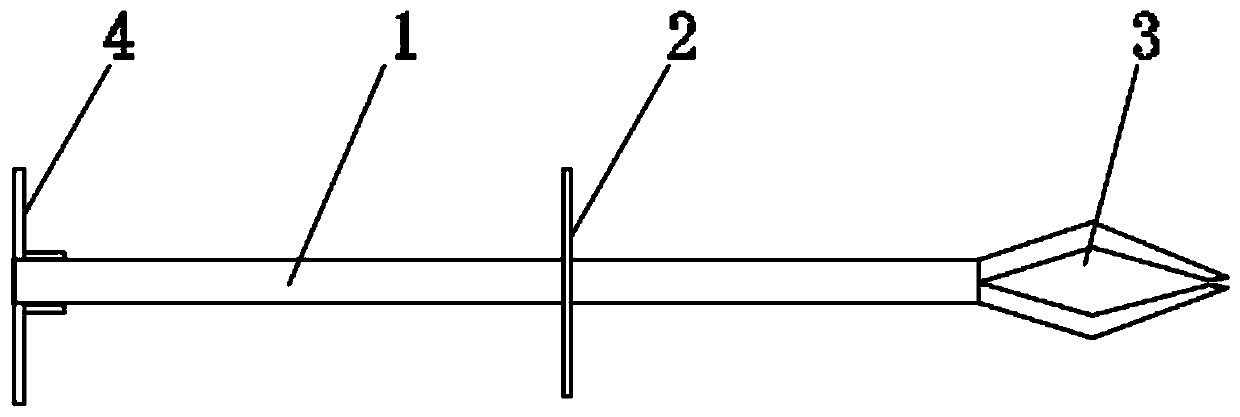

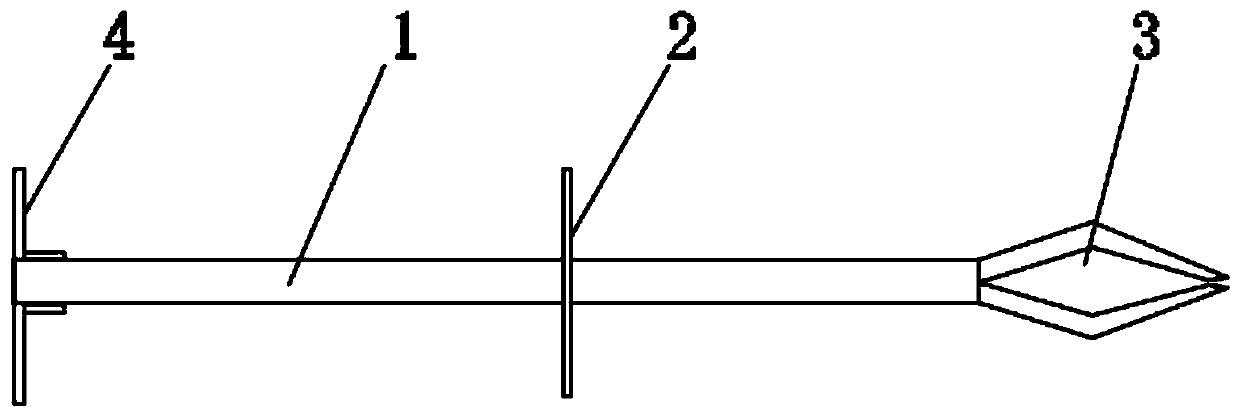

[0015] Such as figure 1 As shown, in this embodiment, an insulation board staple includes a nail body 1, a backing plate 2 arranged in the middle of the nail body 1, and a connecting structure 3 arranged at one end of the nail body 1 and used to connect with the steel bar of the shear wall. And the position-limiting structure 4 that is arranged on the other end of the nail body 1.

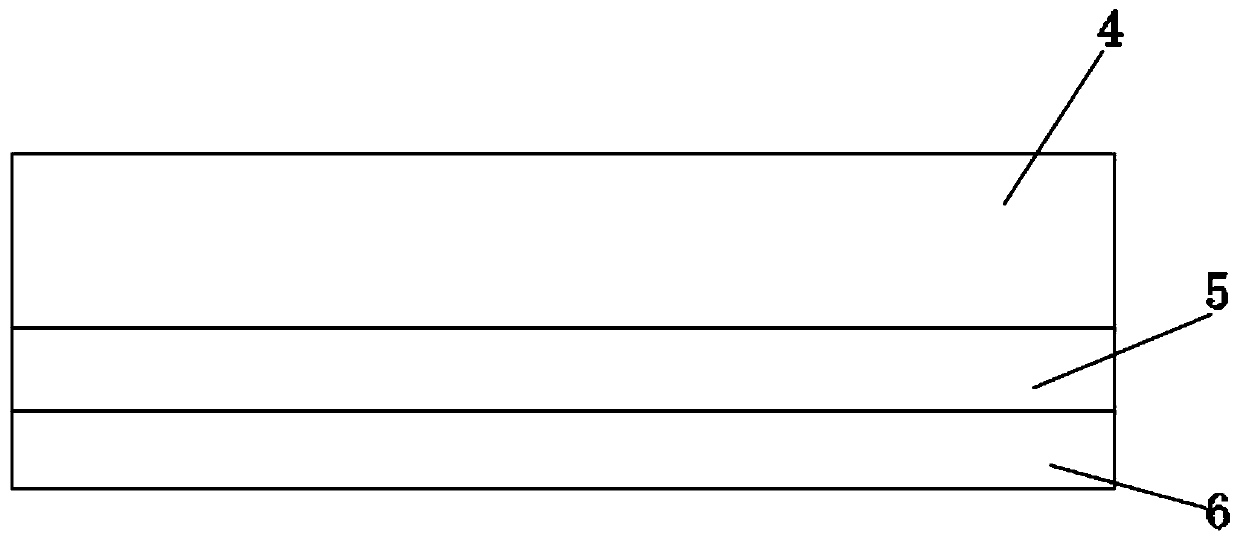

[0016] Such as figure 2 As shown, when constructing the shear wall 5, first set up the steel structure of the shear wall, install the insulation board 7 around the reinforcement of the shear wall, and then pour concrete into the insulation board 7 to form the shear wall 5 and the protective layer 6. Under the existing technical conditions, when installing the insulation board 7, a U-shaped card made of bent iron wire is usually used to pass through the insulation board 7, so that the part of the U-shaped card passing through the insulation board 7 is connected to the steel structure of the shear ...

Embodiment 2

[0019] On the basis of the above embodiments, in this embodiment, the connection structure 3 is a clamping groove capable of clamping with a steel bar. In this way, the clamping groove can be used to directly clamp the steel bar, which is beneficial to improving the construction efficiency, simplifying the structure and reducing the construction cost. In order to improve the stability, it is also possible to use steel wires to wrap around the slot and the steel bar to lock the slot. In this embodiment, other contents not described are the same as those in the foregoing embodiments, so details are not repeated.

Embodiment 3

[0021] Based on the above embodiments, in this embodiment, the limiting structure 4 is detachably connected to the nail body 1 . The detachable connection between the position-limiting structure 4 and the nail body 1 is convenient for loading and unloading the position-limiting structure 4 . In this embodiment, the detachable connection is selected as one of threaded connection and clamping connection. For example, an external thread is provided on the nail body 1, and a threaded hole connected with the external thread is provided on the plate-shaped limiting structure 4. , the connection mode of the detachable connection is the common knowledge and common means of those skilled in the art, and the specific structure and working principle of the detachable connection will not be repeated here. In this embodiment, other contents not described are the same as those in the foregoing embodiments, so details are not repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com