Method for solid stowing of underground roadway and filling system

A dense filling and roadway technology, which is applied in the direction of filling, earthwork drilling, safety devices, etc., can solve the problems of uncompacted gaps, low filling efficiency, and insufficient topping of the upper triangle of the filling roadway, so as to enhance the filling strength and improve Filling efficiency, effect of achieving filling compactness and compression resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

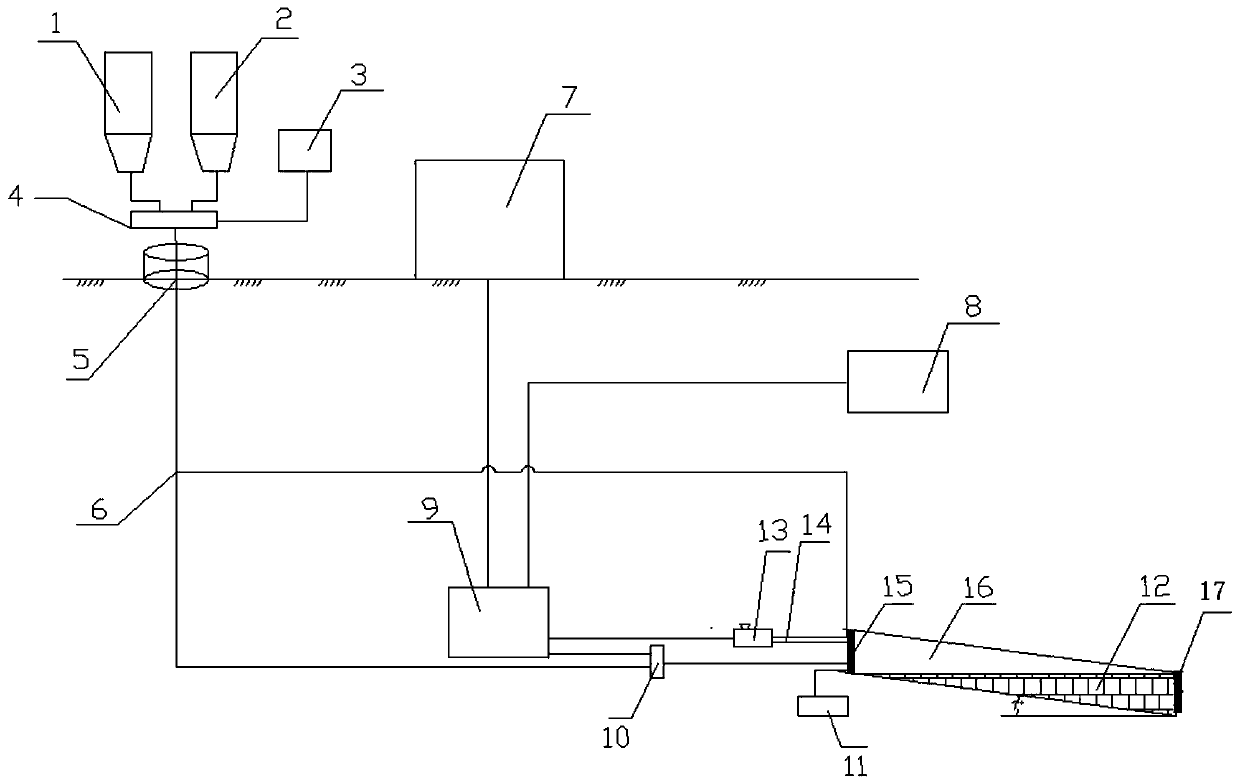

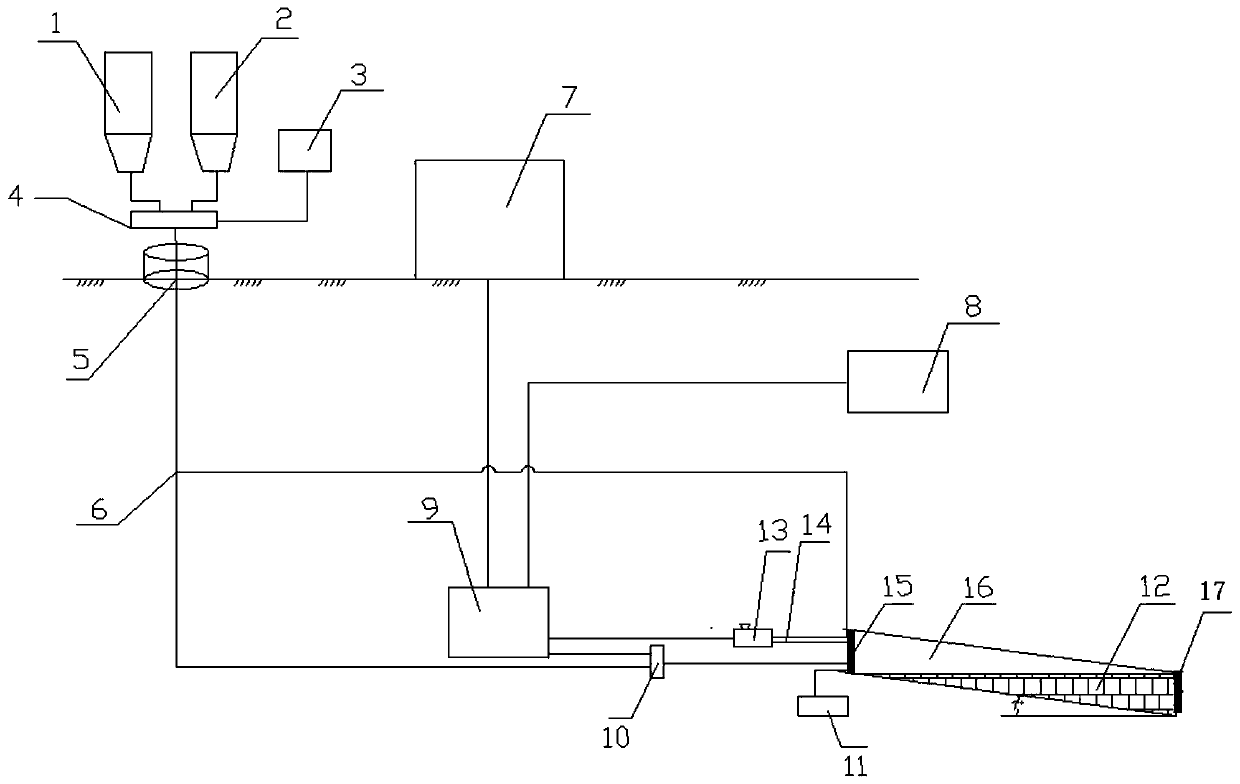

[0025] In order to explain the embodiments of the present invention or the technical solutions in the prior art more clearly, the following briefly introduces the accompanying drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description are only These are some embodiments of the present invention. For those of ordinary skill in the art, other drawings can also be obtained according to these drawings without creative efforts.

[0026] like figure 1 , the filling system of the present invention includes a downhole part and a downhole two parts, wherein:

[0027] The upper part of the well comprises cement tank 1, fly ash tank 2, pool 3, well mixer 4, slurry storage tank 5 and gangue bunker 7;

[0028] The underground part includes a slurry conveying pipeline 6, a gangue separation gangue buffer bin 8 set on the coal mining face, a coal gangue buffer bin 9 set on the filling working face, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com