Compression-resistant optical cable

An optical cable and cable core technology, which is applied to insulated cables, communication cables, flat/ribbon cables, etc., can solve the problems of increasing resources and waste, and achieve the effect of simple production process, resource saving and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

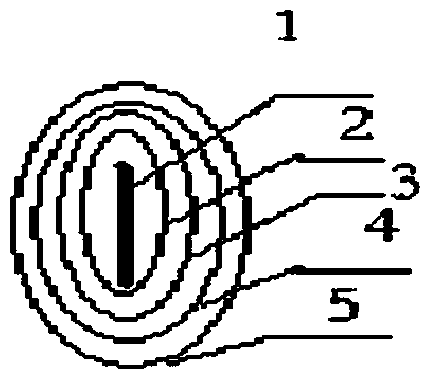

[0019] Such as figure 1 A kind of anti-pressure optical cable shown, it comprises flat cable core 1, insulator 2, inner sheath 3, armouring 4, outer sheath 5, wherein, flat cable core comprises optical fiber and metal wire, described optical fiber and The metal wires are interwoven and pressed into a flat shape; the flat cable core 1 is wrapped by the insulator 2, the inner sheath 3 is wrapped on the surface of the insulator 2, and the armor 4 is arranged on the inner sheath 3 and the outer sheath 5; the inner sheath, the armor, and the outer sheath are all set to a flat shape matched with the cable core, and the outer sheath 5 is a thin copper strip, which is connected with the armor 4 Form an integrated shielding layer.

[0020] The present invention when making, its concrete steps are as follows:

[0021] a. First, the optical fiber and the metal wire are twisted through a stranding machine, and then pressed into a flat cable core 1 through an extrusion machine;

[0022]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com