Service aid of air-assisted type urea metering pump

A technology of service tools and metering pumps, which is applied in the field of air-assisted SCR post-processing systems, can solve problems that cannot be effectively solved, complex structures, high costs, etc., achieve good economy and practicability, low computer requirements, and realize The effect of fault diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific drawings and embodiments.

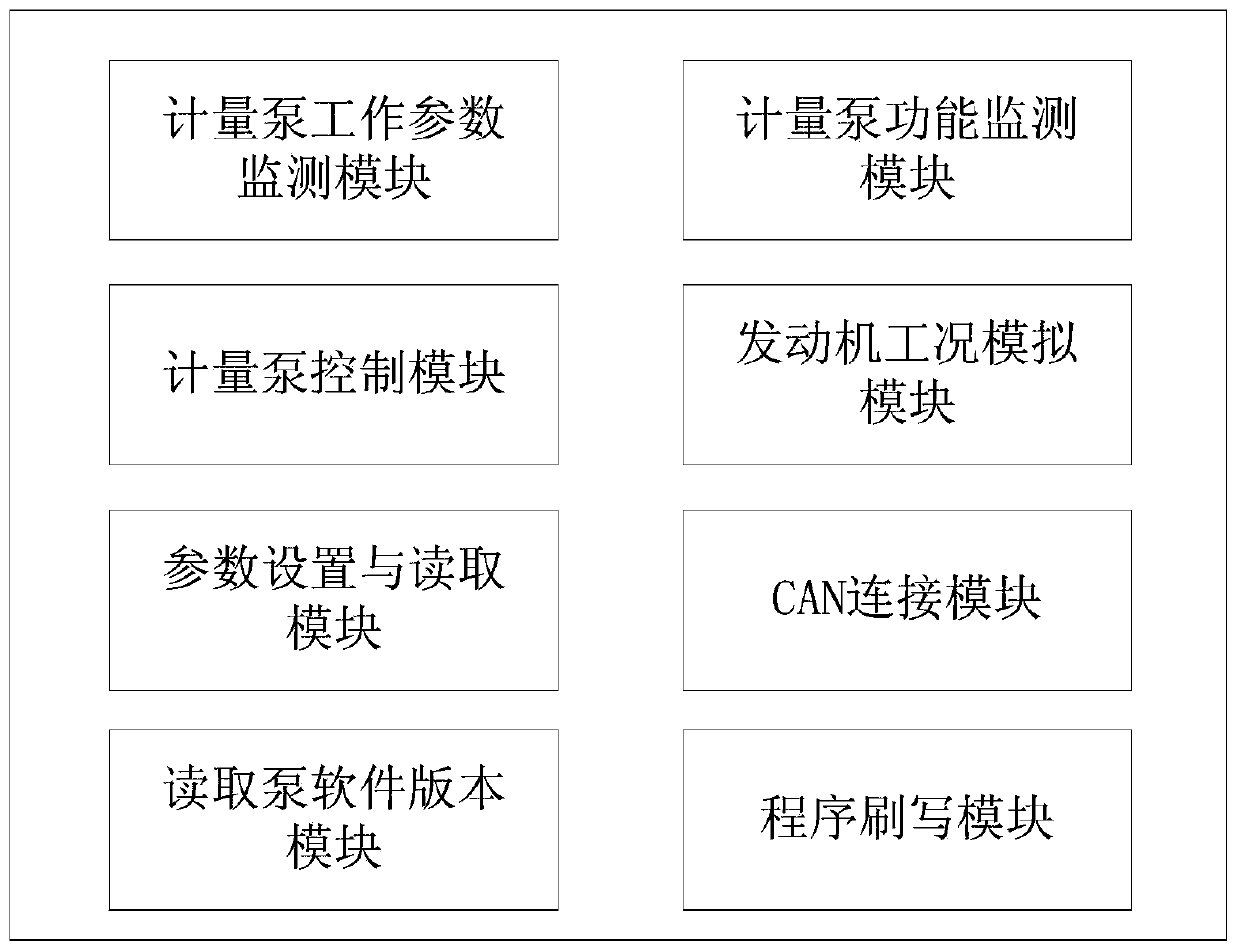

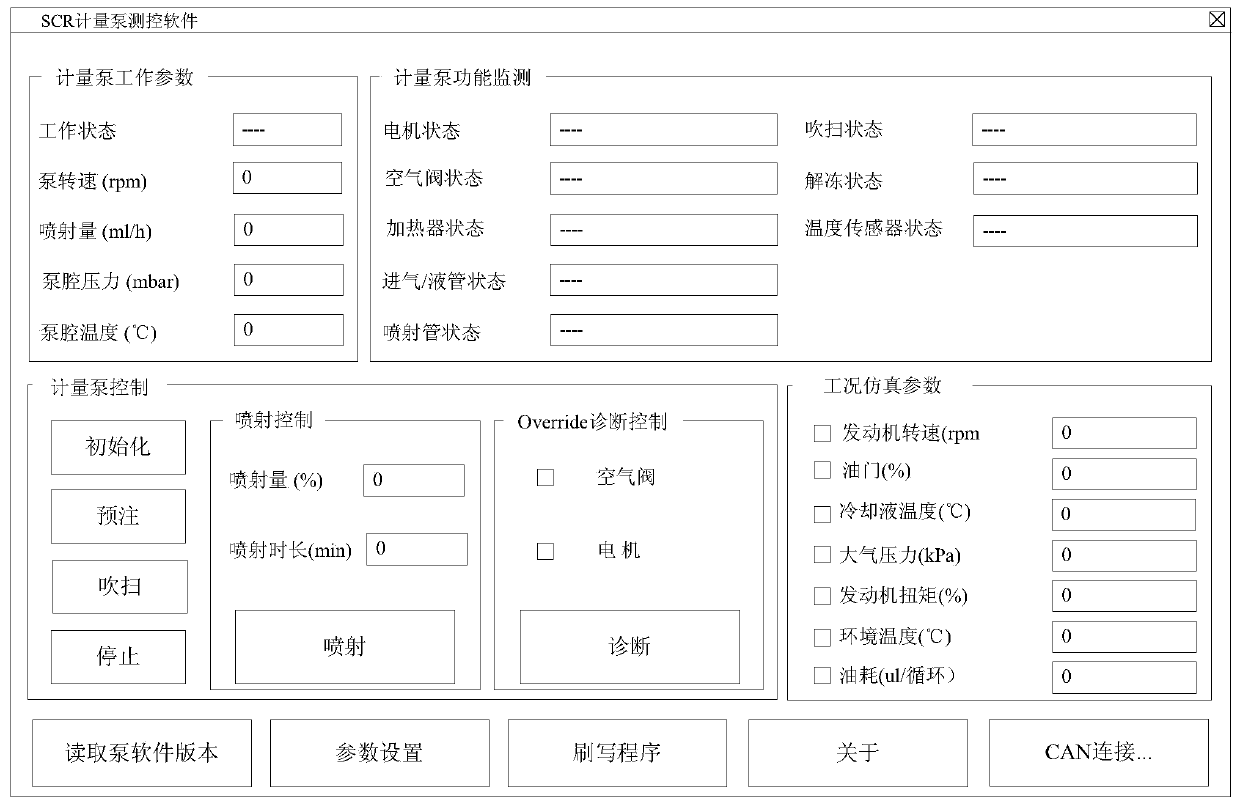

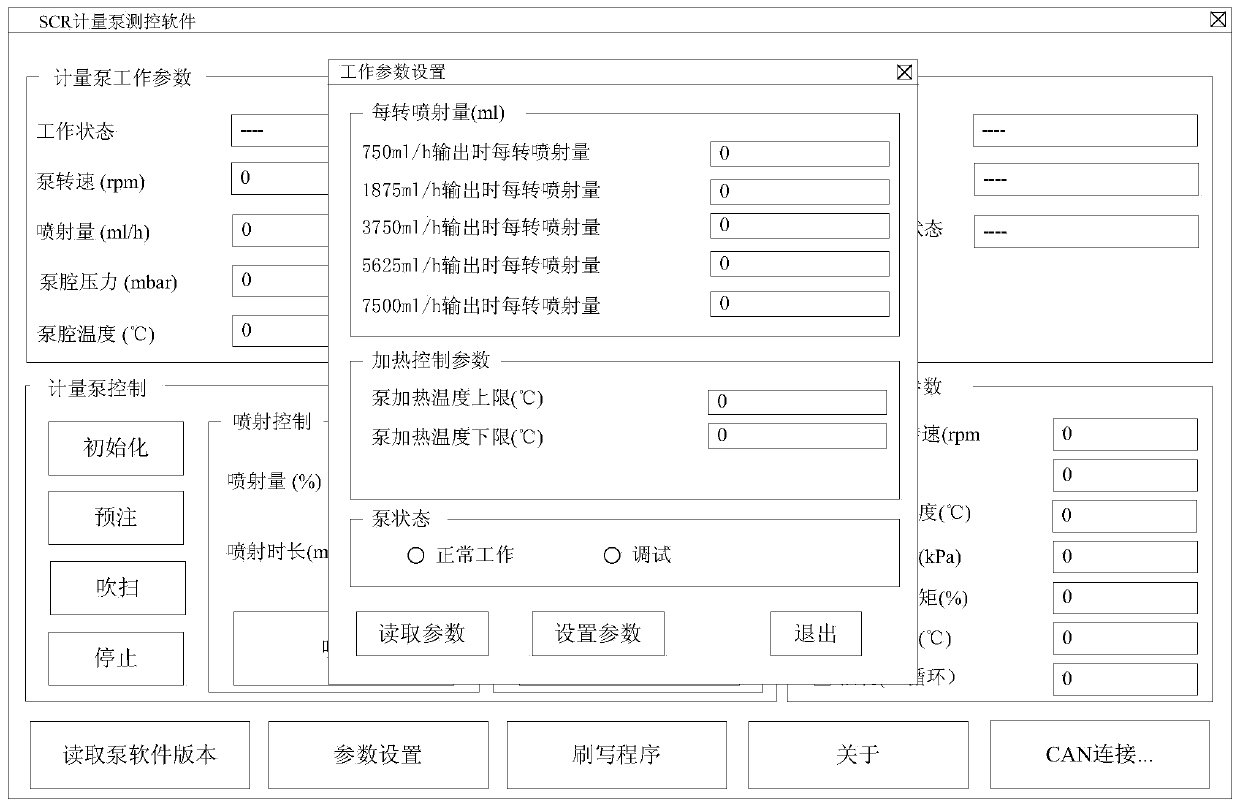

[0025] Such as figure 1 As shown, the present invention proposes an air-assisted urea metering pump service tool (hereinafter referred to as the service tool), including: a metering pump working parameter monitoring module, a metering pump function monitoring module, a metering pump control module, an engine operating condition simulation module, and a parameter Setting and reading module, CAN connection module;

[0026] The service tool is a software installed on the computer. When in use, the computer installed with the service tool is connected to the air-assisted urea metering pump (hereinafter referred to as the metering pump) through the CAN bus; various information and data of the urea metering pump are passed through the CAN bus. send to computer;

[0027] The working parameter monitoring module of the metering pump is used to monitor the working stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com