Quasi-zero-stiffness vibration isolator with horizontal damper

A technology of quasi-zero stiffness and horizontal damping, which is applied in the direction of shock absorbers, spring/shock absorber functional characteristics, shock absorbers, etc., can solve the problem that linear vibration isolators cannot have high load-bearing capacity and low-frequency vibration isolation performance, etc. Achieve the effect of suppressing system resonance, wide application and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

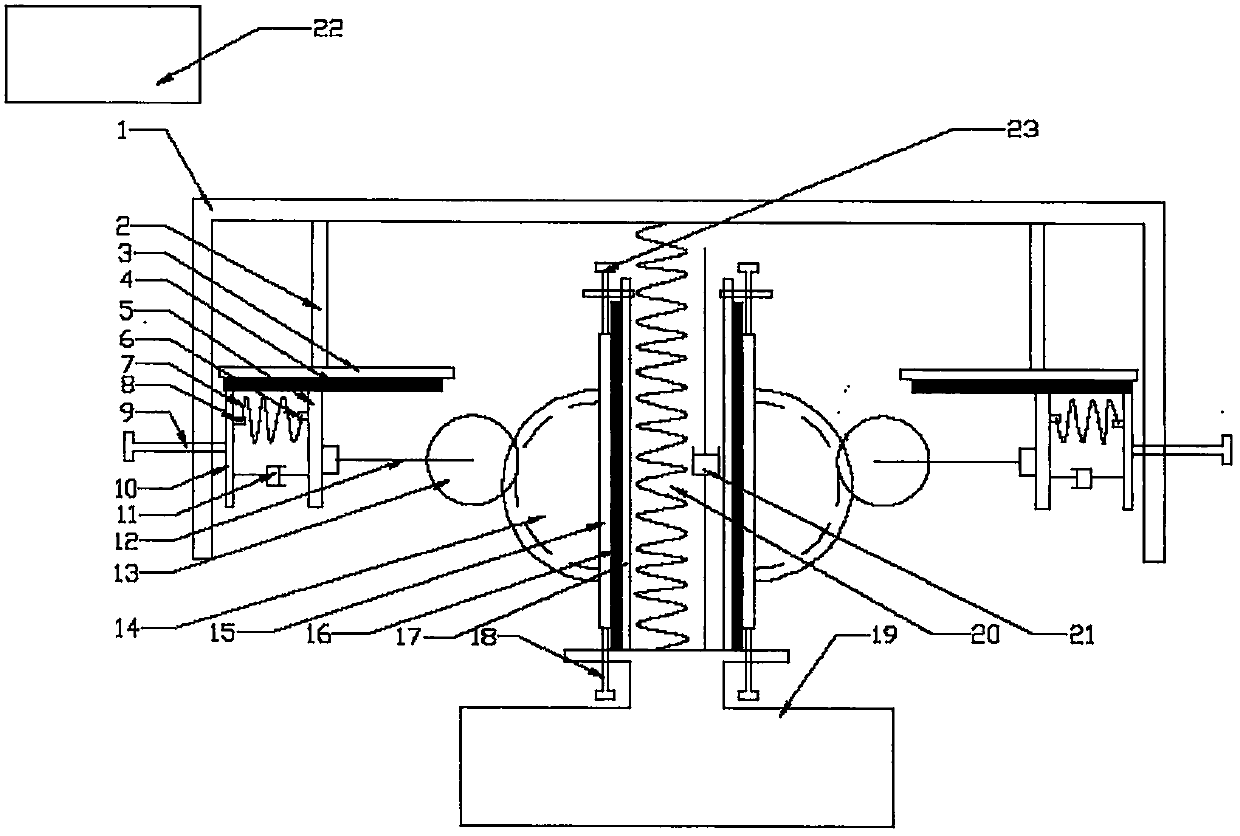

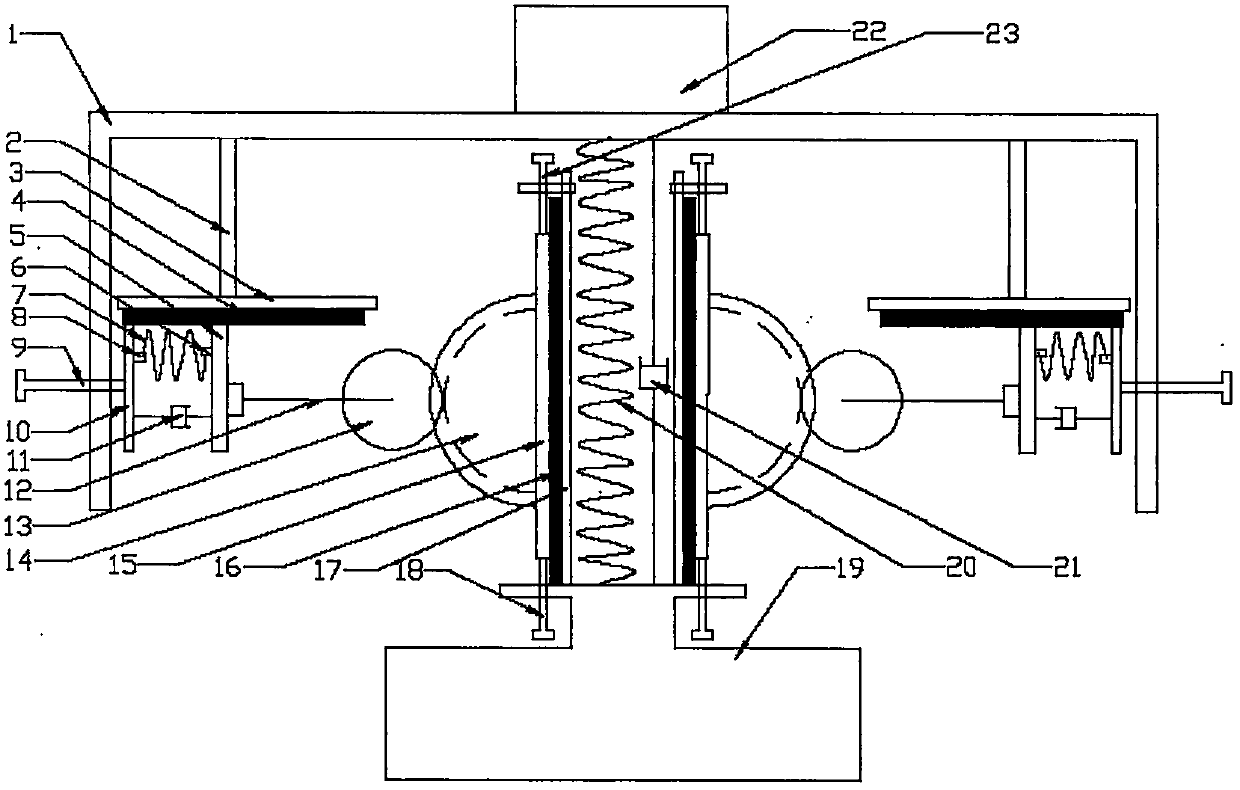

[0018] like figure 1 and figure 2 As shown, an embodiment of the present invention includes a support platform 1, the support platform 1 is supported by a base 19 through a vertical spring 20, the support platform 1 is connected to the upper end of the vertical spring 20, and the lower end of the vertical spring 20 is fixed on the base 16 The upper surface of the upper surface; between the base 16 and the support platform 1 is provided with a vertical damper 21; under the support platform 1 is provided with a boom 2, and the bottom end of the boom 2 is fixed with a horizontal plate 3 with a linear guide rail 4 ; Linear guide rail 4 is provided with fixed block 10 near one end of support platform 1; Connect by horizontal spring 7 and damper 11; The right side of sliding block 5 is equipped with connecting rod 12; Connecting rod 12 is equipped with roller 13 near the side of vertical spring 20; Install baffle plate 17 on the left side of vertical spring 20 , the lower surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com