High-precision self-matching boundary dimension measurement method applied to high-speed condition

A technology of external dimensions and measurement methods, which is applied in the direction of measuring devices, instruments, and the use of ultrasonic/sonic/infrasonic waves, etc., can solve problems such as mechanical installation deviation, deviation value amplification, and probe axis deviation, so as to eliminate influence and eliminate mechanical installation errors and the effect of acquisition system error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

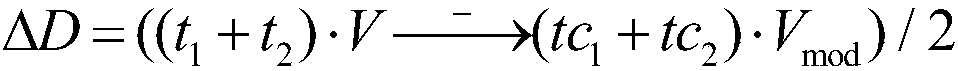

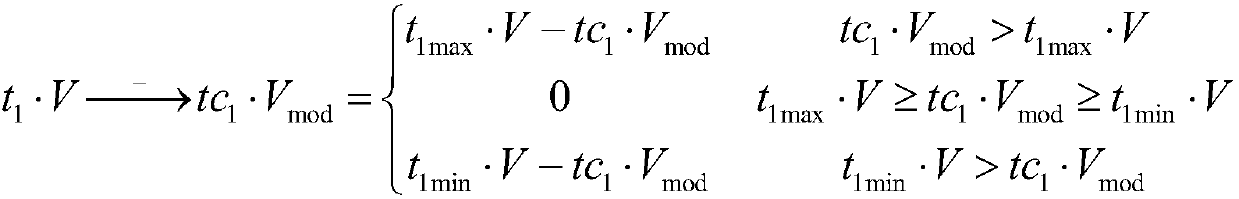

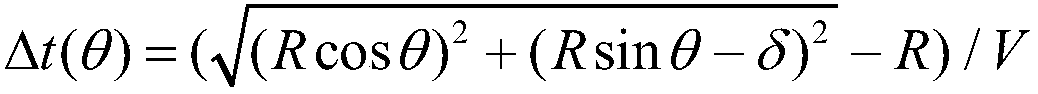

[0061] A method for measuring high-precision self-matching external dimensions under high-speed conditions, the method specifically includes:

[0062] Step 1. Calibrate the collected data of the inspected pipe;

[0063] Place the calibrated pipe in the detection system, and use two probes to collect the external dimension data of the inspected pipe, where the length of the collected signal is greater than 20 cycles, and the data collected by the two probes are respectively recorded as t 1 and t 2 ; Among them, the probe rotates one week as a cycle;

[0064] Step 2. Perform periodic analysis on the collected calibration signals of the inspected pipes;

[0065] Step 2.1, perform signal preprocessing, and filter out abnormal signals;

[0066] Use methods such as frequency domain filtering, median filtering or median filtering to filter out abnormal signals such as high frequency bands and burrs in the collected signal;

[0067] Step 2.2, calculating and obtaining the flag bit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com