A friction coefficient detection device

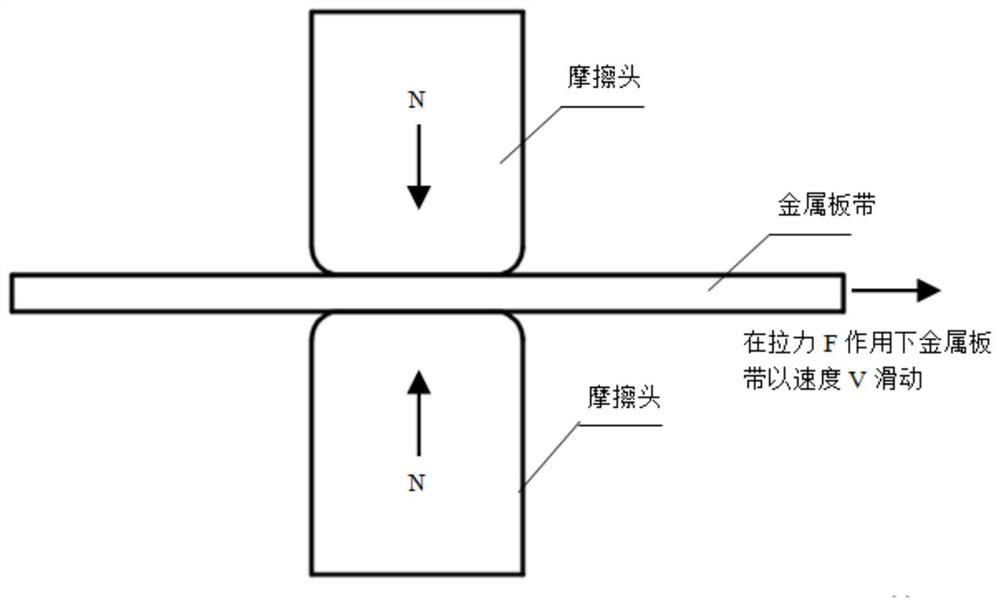

A detection device and a friction coefficient technology, applied in the field of detection devices, can solve the problems of not considering the influence of pressure N and sliding speed V detection results, and achieve the effect of increasing stability and accuracy and preventing displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

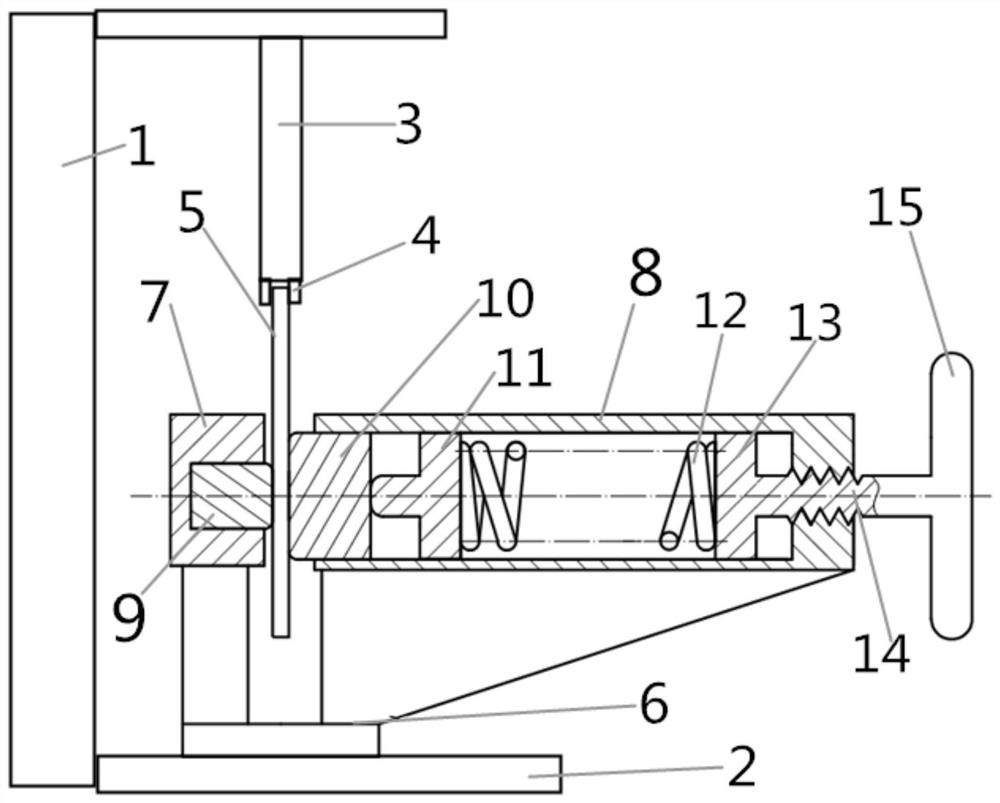

[0040] The present invention provides a friction coefficient detection device, which includes a base 6 connected to the test bench 2 of the universal tensile testing machine 1, a first sleeve 7 and a second sleeve respectively connected to the base 6 with openings facing each other Barrel 8;

[0041] The first sleeve 7 is provided with a first friction head 9;

[0042] A second friction head 10, a pressure sensor 11 and a pressure adjustment assembly are sequentially provided in the second set 8 from the opening to the bottom;

[0043] The outer wall of the first friction head 9 is connected to the inner wall of the first sleeve 7, and the outer wall of the second friction head 10 is connected to the inner wall of the second sleeve 8;

[0044] The first friction head 9 and the second friction head 10 are coaxial; the gap between the first friction head 9 and the second friction head 10 is used to set the sample 5; the sample 5 and the second friction head 10 are coaxial; The...

Embodiment 2

[0055] The present invention provides a friction coefficient detection device, which includes a base 6 connected to the test bench 2 of the universal tensile testing machine 1, a first sleeve 7 and a second sleeve respectively connected to the base 6 with openings facing each other Barrel 8;

[0056] The first sleeve 7 is provided with a first friction head 9;

[0057] A second friction head 10, a pressure sensor 11 and a pressure adjustment assembly are sequentially provided in the second set 8 from the opening to the bottom;

[0058] The outer wall of the first friction head 9 is connected to the inner wall of the first sleeve 7, and the outer wall of the second friction head 10 is connected to the inner wall of the second sleeve 8;

[0059] The first friction head 9 and the second friction head 10 are coaxial; the gap between the first friction head 9 and the second friction head 10 is used to set the sample 5; the sample 5 and the second friction head 10 are coaxial; The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com