Electric connecting fitting and method thereof

A technology of electrical connection and fittings, applied in the direction of winding connectors, clip-connected conductor connections, overhead line/cable equipment, etc., can solve problems such as far-fetched, achieve high versatility and operability, simple selection and structural design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

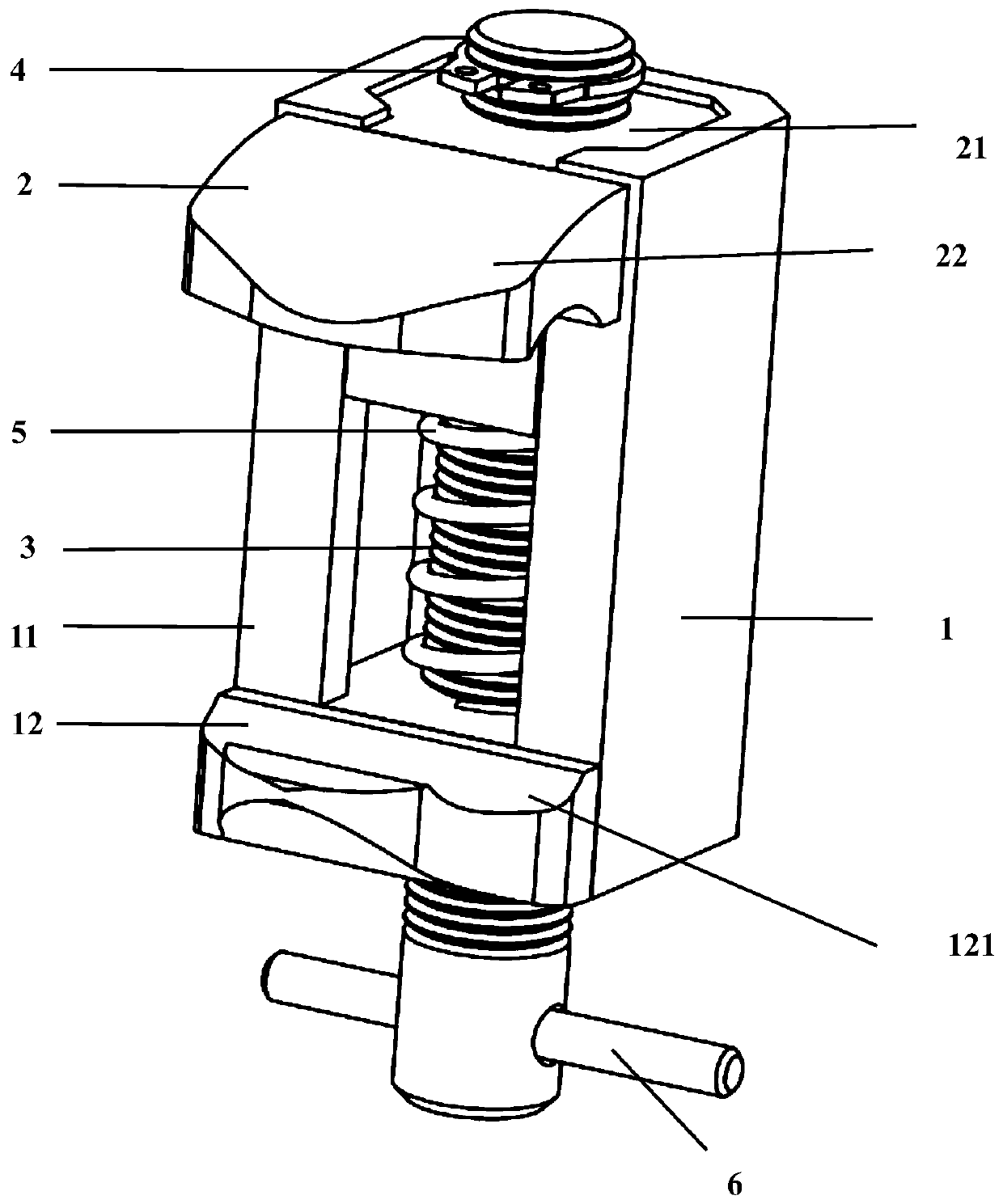

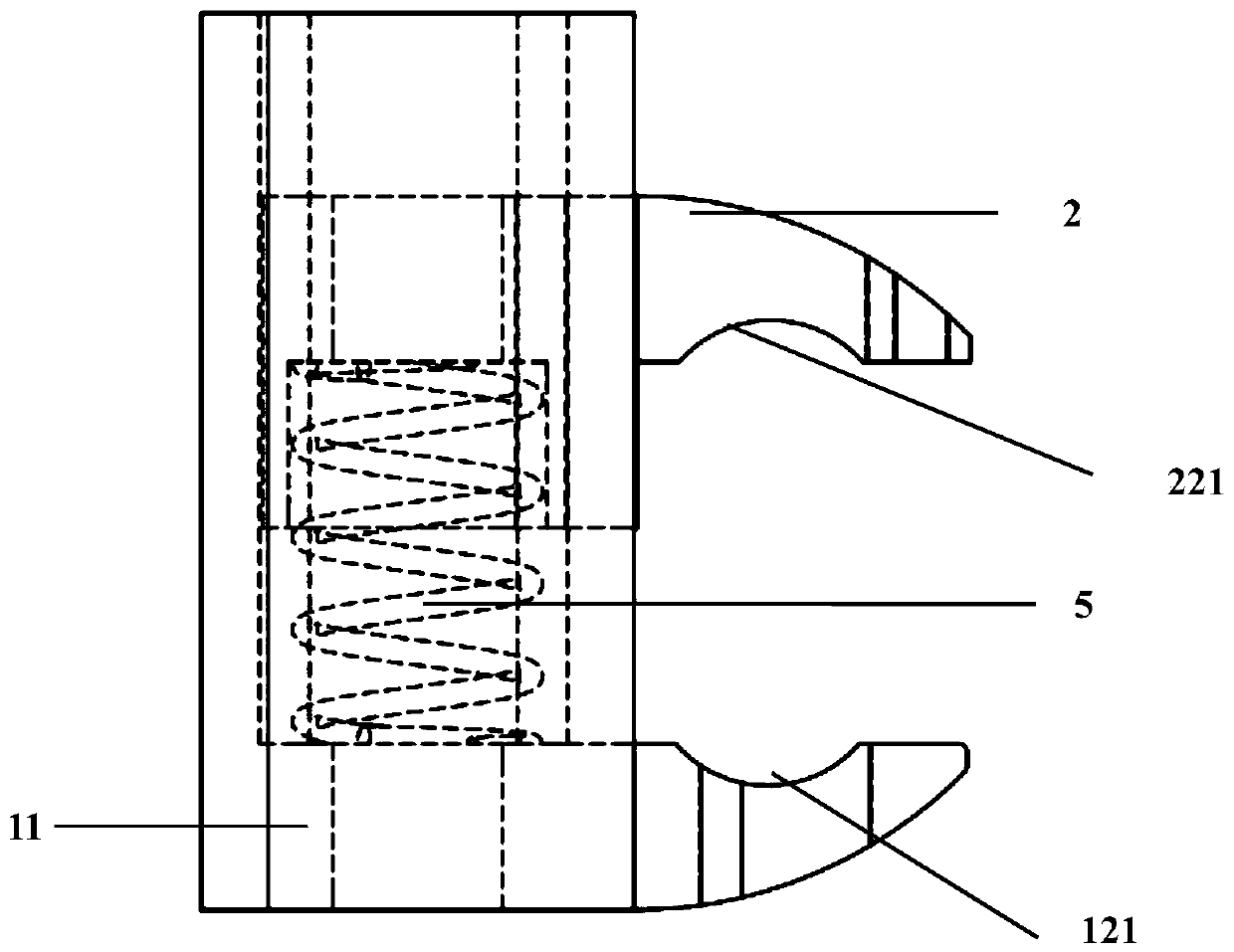

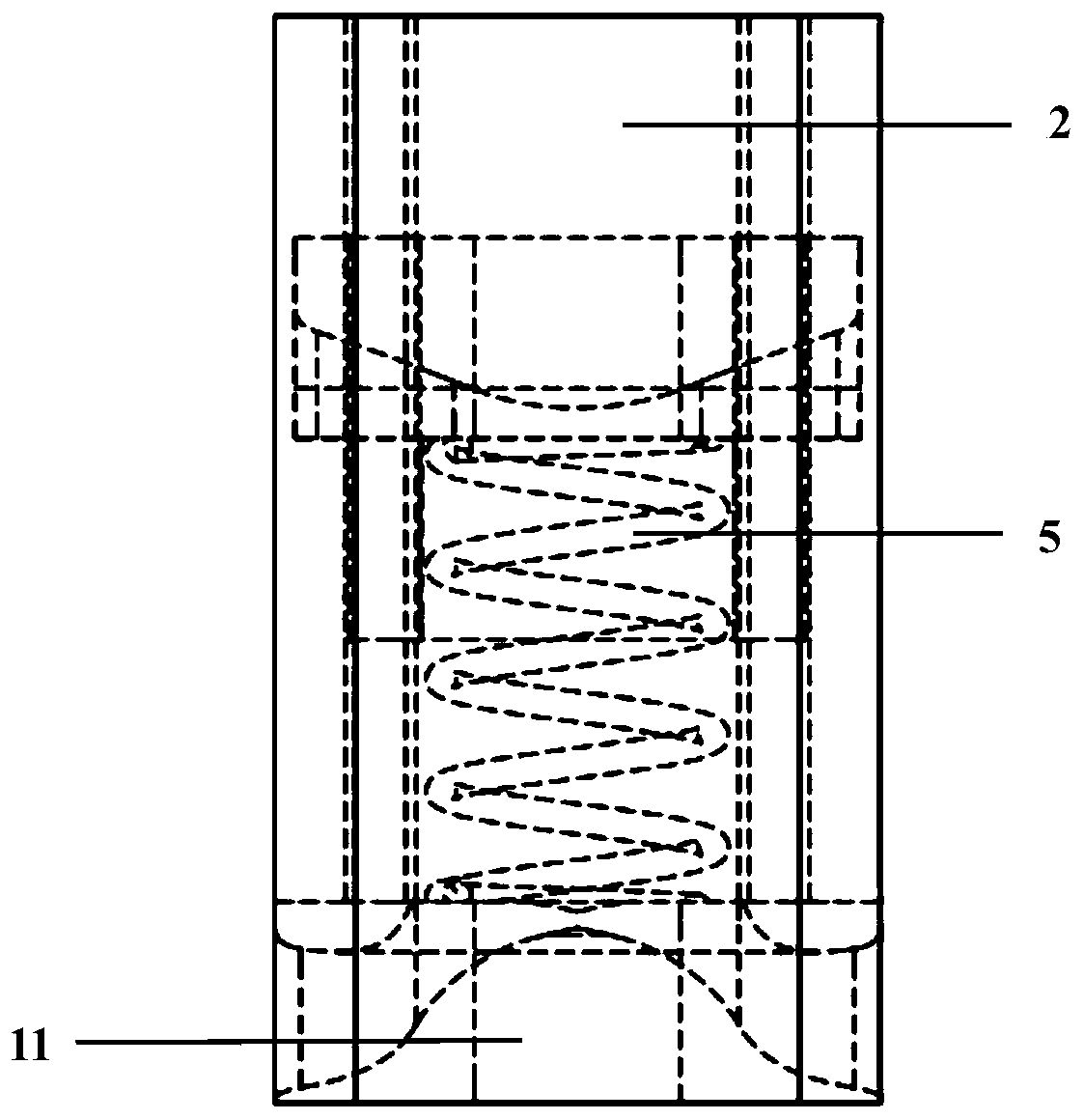

[0037] by reading reference Figure 1-Figure 10 The features, objects and advantages of the present invention will become more apparent from the detailed description of non-limiting examples. See the illustration of an embodiment of the invention Figure 1-Figure 10 , the present invention will be described in more detail below. However, this invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein.

[0038] Such as Figure 1-Figure 10 As shown, the electrical connection fitting of the present invention includes a fitting body 1 , a bolt 3 , a compression spring 5 and a clip 2 for clamping wires. The bottom of the fitting body 1 is a fitting base 11, and the lower end of the fitting base 11 is provided with a first bolt hole 111 for the bolt 3 to penetrate from bottom to top.

[0039] Such as figure 1 , Figure 5 with Figure 8 As shown, the inner wall of the hardware body 1 is provided with an "I"-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com