H-bridge circuit with current limiting function

A bridge circuit and functional technology, applied in the field of H bridge circuit, can solve the problems such as difficulty in adjusting parameters, inapplicability of direct drive, small output current, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

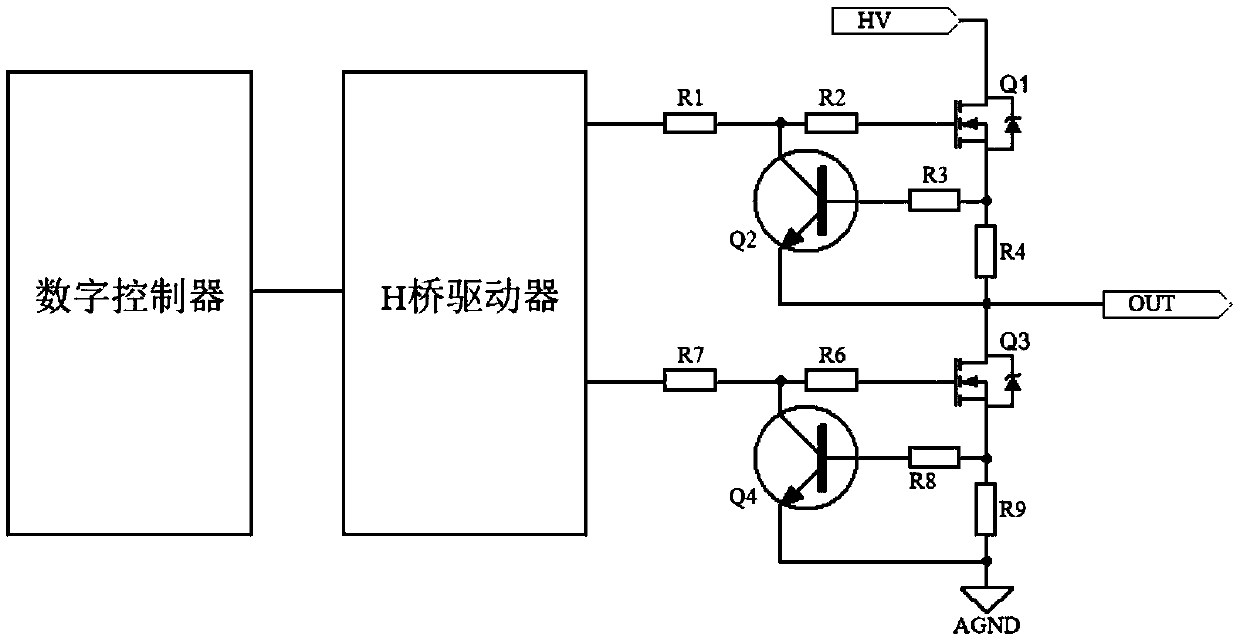

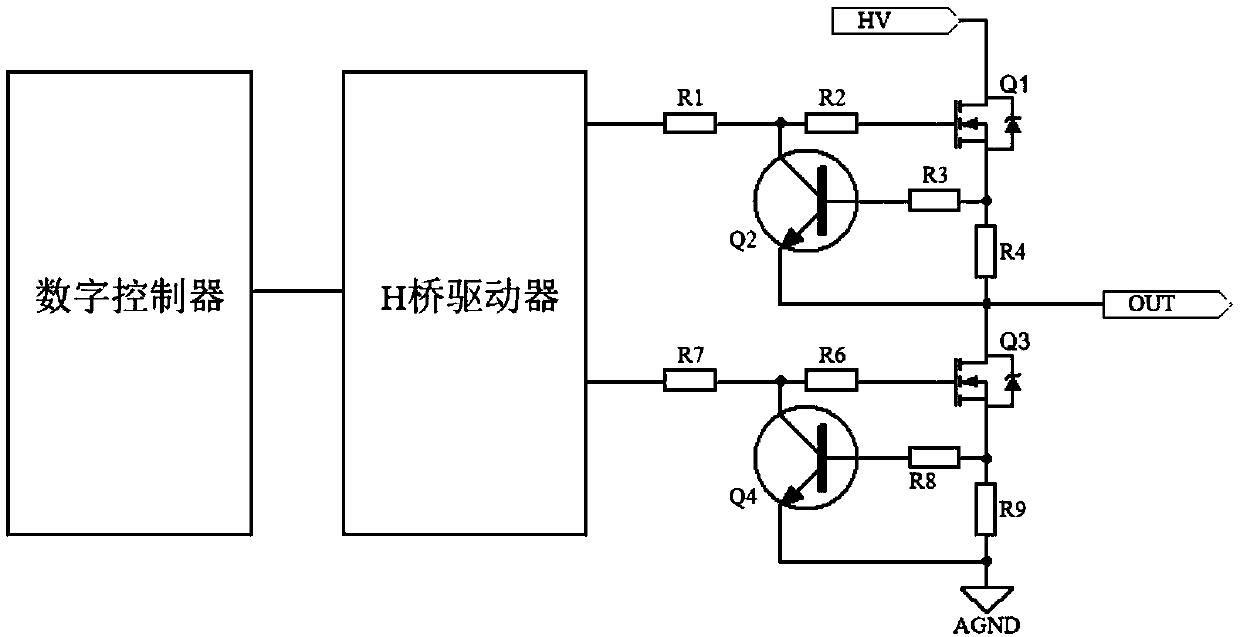

[0021] like figure 1 Shown is the block diagram of the circuit structure of the present invention.

[0022] The H-bridge drive circuit with current limiting function includes an H-bridge, an H-bridge driver, and a current-limiting unit; the H-bridge includes MOS transistors Q1, Q3, and gate resistors R1, R2, R6, and R7; the current-limiting unit includes Transistors Q2, Q4, base resistors R3, R8, and sampling resistors R4, R9; the gate resistors R1, R2, R6, and R7 can be zero; HV is the high-voltage side power supply of the H-bridge, and AGND is the high-voltage side of the H-bridge sideways.

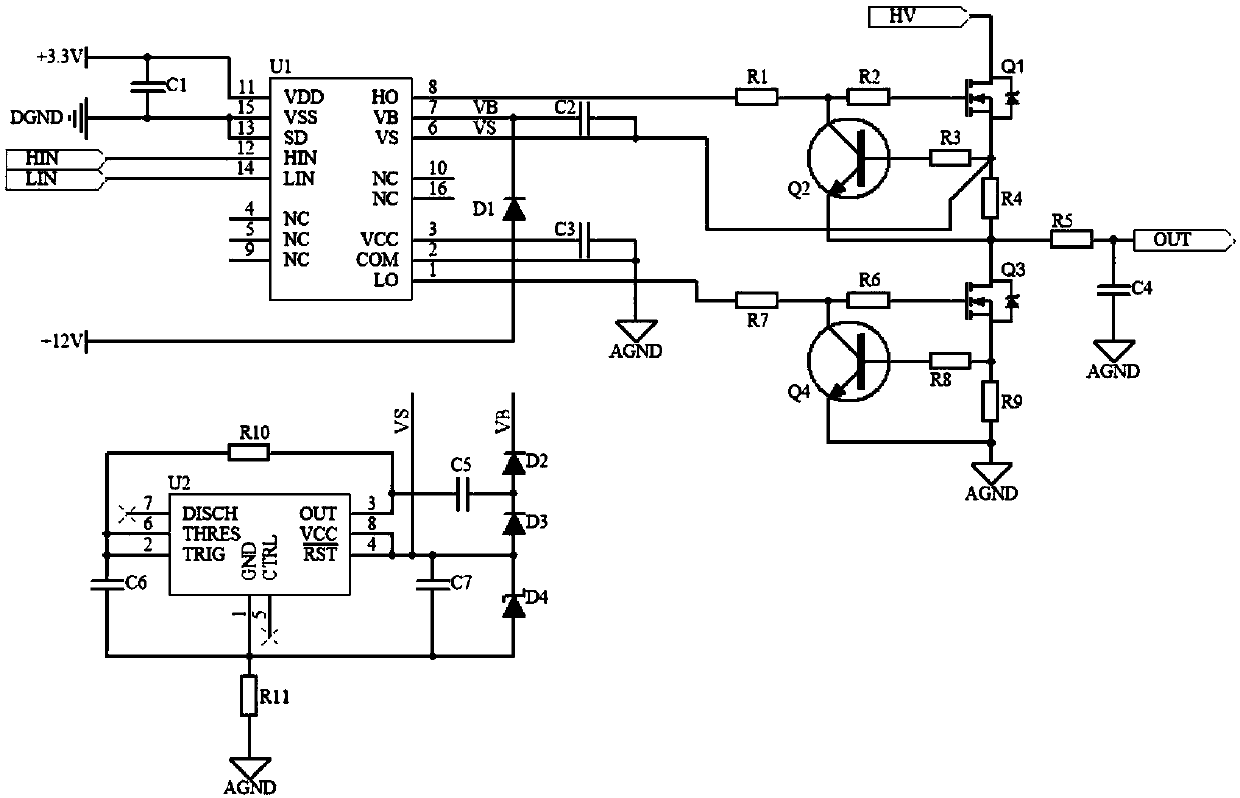

[0023] like figure 2 Shown is the circuit connection diagram of the present invention.

[0024] U1 is the H-bridge driver chip IR2110S, the digital controller is connected to U1 through the HIN and LIN interfaces, and U1 is connected to the H-bridg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com