Granulator with automatic feeding

A ball forming machine and feeding technology, which is applied in mixers, mixers with rotary stirring devices, and smoke removal, etc., can solve the problems of no auxiliary stirring and feeding function, inconvenient adjustment of the use height, and easy to be affected by dust. , to achieve the effect of increasing the auxiliary stirring and feeding function, increasing the spraying function, and ensuring the convenience of operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

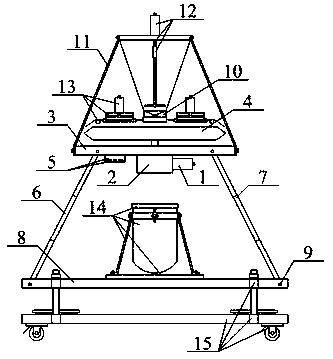

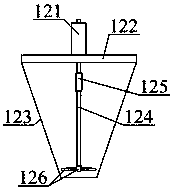

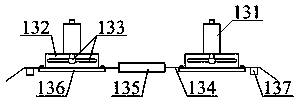

[0044] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, a kind of automatic feeding type ball forming machine comprises a ball forming motor 1, a reducer 2, a frame 3, a ball forming plate 4, an automatic control switch 5, a main telescopic adjustment rod 6, a slave telescopic adjustment rod 7, a bottom Frame 8, movable bolts and nuts 9, control valve 10 for feeding, support frame 11, auxiliary stirring feeder 12, dust-proof self-adsorption processor 13, temporary storage tank structure 14 for materials after forming balls, and height rotation adjustment The mobile frame 15, the horizontal left end bolt of the ball forming motor 1 is installed in the middle position of the right end of the reducer 2; the bolt of the reducer 2 is installed in the bottom middle position of the frame 3; the middle position of the ball forming disc 4 The key is connected to the upper end of the outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com