Soil leaching remediation tower

A soil leaching and leaching technology, applied in the field of soil leaching and repairing towers, can solve the problem that the leaching solution cannot be fully leached, etc., so as to speed up the leaching speed, improve the leaching efficiency, and achieve uniform and sufficient leaching. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

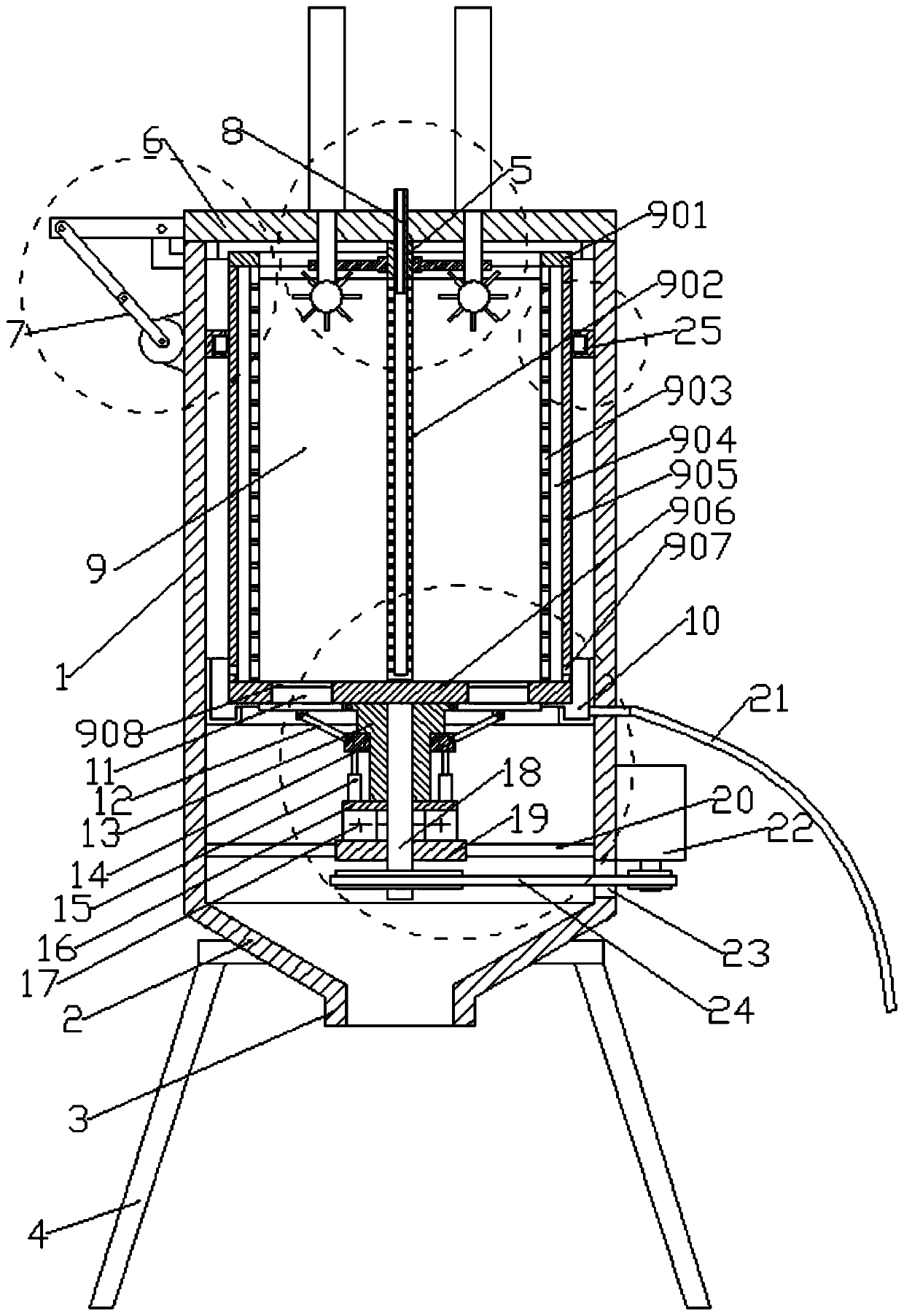

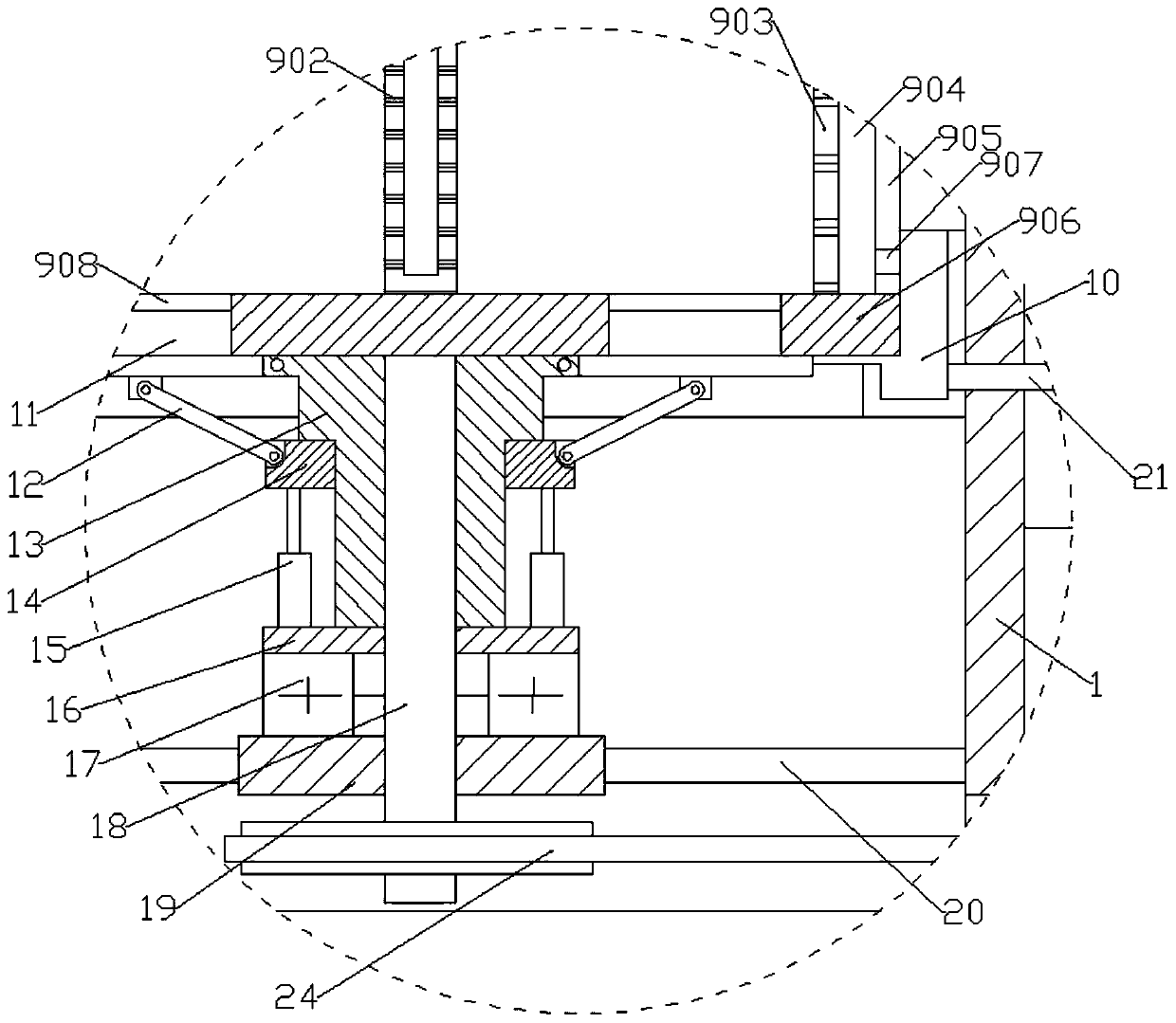

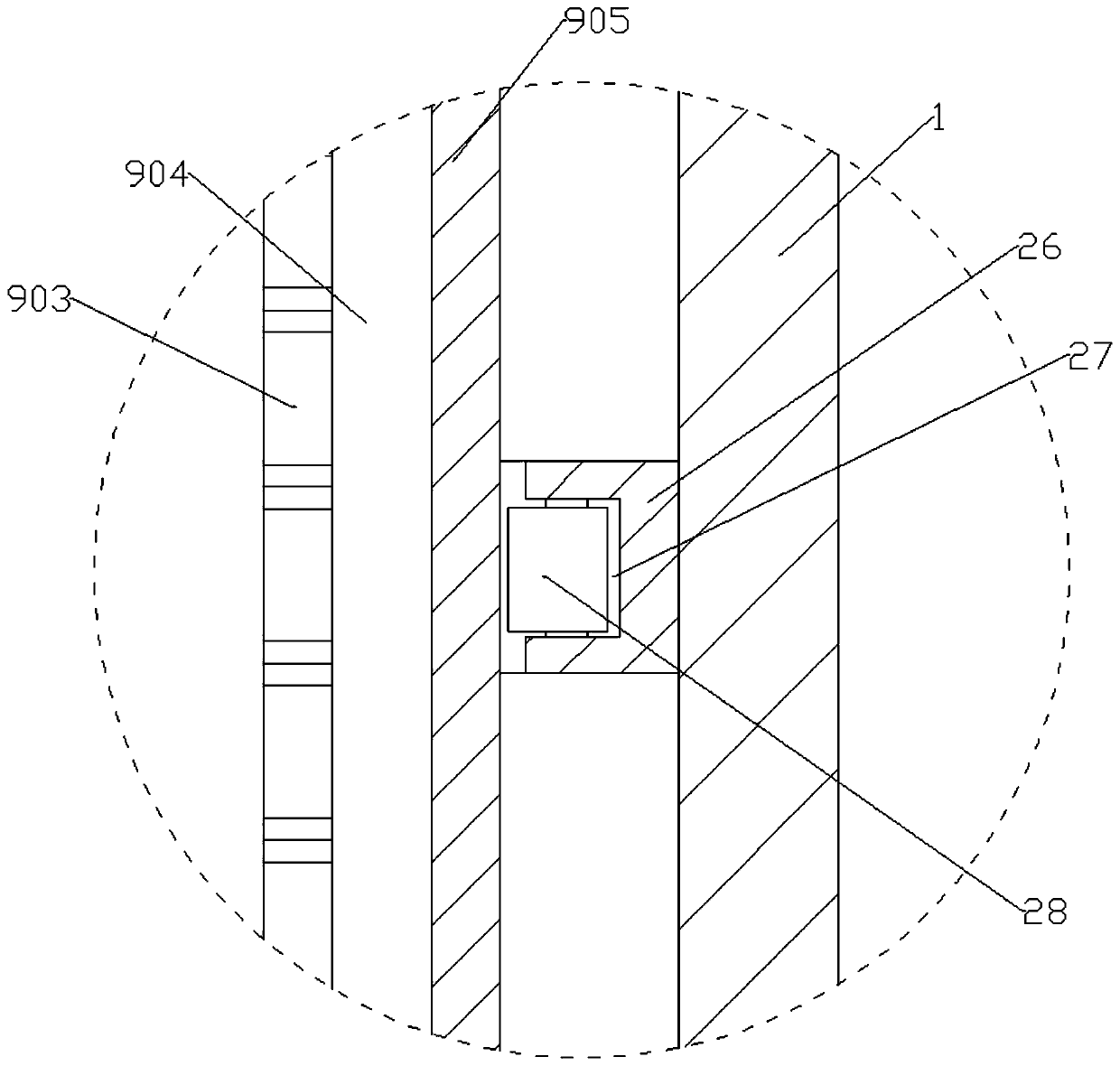

[0020] Referring to the accompanying drawings: a soil washing repair tower in the present embodiment includes a tower cover 6, a cylindrical tower body 1 and a conical tower bottom 2, and the center of the tower cover 6 is provided with a drain for accessing the eluent. The water inlet pipe 8, the tower body 1 is provided with a rinsing rotary bucket 9 for rinsing the soil, and the leaching rotary bucket 9 is composed of a barrel body, a barrel bottom plate 906 and a eluent diffusion pipe 902 in the center of the barrel. The barrel body is composed of a filter cartridge 903 and an outer cylinder 905, a drainage interlayer 904 is provided between the filter cartridge 903 and the outer cylinder 905, a circle of drainage holes 907 is provided on the bottom side wall of the outer cylinder 905, and a drainage hole 907 is arranged outside the drainage hole 907. An annular sump 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com