Remediation device and method for hexavalent chromium contaminated soil

A technology of polluted soil and remediation method, which is applied in the field of remediation devices for hexavalent chromium polluted soil, can solve the problems of increasing the amount of solidified treatment wastewater, many times of rinsing, and many eluents, etc. Good effect and consumption saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The repair process of the existing hexavalent chrome contaminated soil is mainly to repeat the contaminated soil for repeatedly collining through the collections, so that the six-price chromium in the soil is completely collected, and the curing is carried out, and the number of elution is more, efficiency Low, and consumes a lot of elongated liquid, increase subsequent curing treatment waste water.

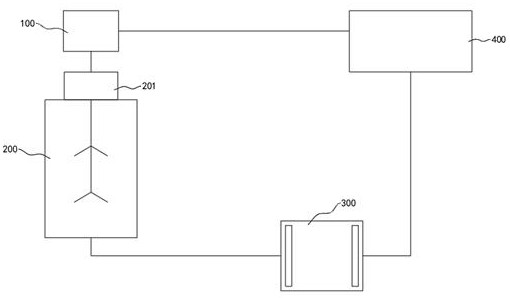

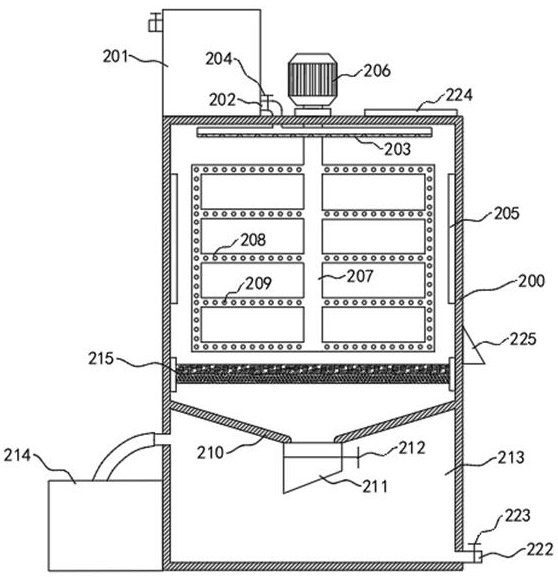

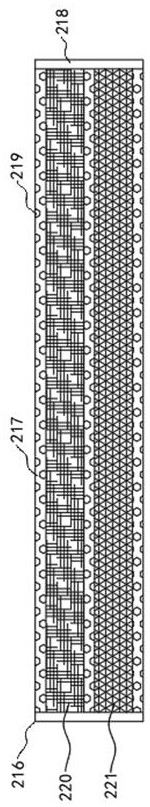

[0047] In order to solve the problem of prior art, the embodiment of the present invention provides a repairing apparatus and method of a six-rate chromium contaminated soil, wherein the repair method comprises the steps of:

[0048]S1. Formulate the collapse, and the illenol is preheated (a preheating temperature is 40 ° C), and the preheated collisher is stirred with the contaminated soil at 60 ° C for 3 h. In heating environments, hexavalent chromium can be increased. The collisher can be a kind of hydrochloric acid, citric acid, oxalic acid, and acetic acid. This example i...

Embodiment 2

[0068] Embodiments of the present invention provide a repair method for a six-rate chrome contaminated soil, including the following steps:

[0069] S1. Formulate the collapsed liquid and preheat the collapse (a preheating temperature of 45 ° C), and the preheated collapsed liquid is stirred at 70 ° C for 4 h at 70 ° C after stirring. The colloration is one of hydrochloric acid, citric acid, oxalic acid, and acetic acid. This example is preferably pH 2.5 citric acid solution.

[0070] After the stirring is completed, the contaminated soil is filtered, and the soil is removed by the preheated straw liquid to obtain the suction filtration.

[0071] S3. The filtration fluid enters an electrochemical reaction tank, and the hexavalent chromium is reduced to trivalent chromium by electrochemical reaction, and chromium hydroxide precipitation is formed.

[0072] S4. The electrolytic filtration liquid enters the precipitated tank, precipitates chromium hydroxide, and recovered the superna...

Embodiment 3

[0074] Embodiments of the present invention provide a repair method for a six-rate chrome contaminated soil, including the following steps:

[0075] S1. Formulate the collapsed liquid, and perform preheating (50 ° C with a preheating temperature), and the preheated collisher is stirred with the contaminated soil at 80 ° C for mixing for 5 h. The colloration is one of hydrochloric acid, citric acid, oxalic acid, and acetic acid. This example is preferably a citric acid solution of pH3.

[0076] After the stirring is completed, the contaminated soil is filtered, and the soil is removed by the preheated straw liquid to obtain the suction filtration.

[0077] S3. The filtration fluid enters an electrochemical reaction tank, and the hexavalent chromium is reduced to trivalent chromium by electrochemical reaction, and chromium hydroxide precipitation is formed.

[0078] S4. The electrolytic filtration liquid enters the precipitated tank, precipitates chromium hydroxide, and recovered th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com