Method for repairing heavy metal polluted bottom mud through combination of leaching and stacking

A technology of polluted sediment and joint restoration, applied in chemical instruments and methods, sludge treatment, water pollutants, etc., can solve the problems of increased biological toxicity of heavy metals, reduced humus content, difficult to use microorganisms to degrade organic matter, etc. The effect of chemical utilization, inhibition of organic matter mineralization, and efficient removal of fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

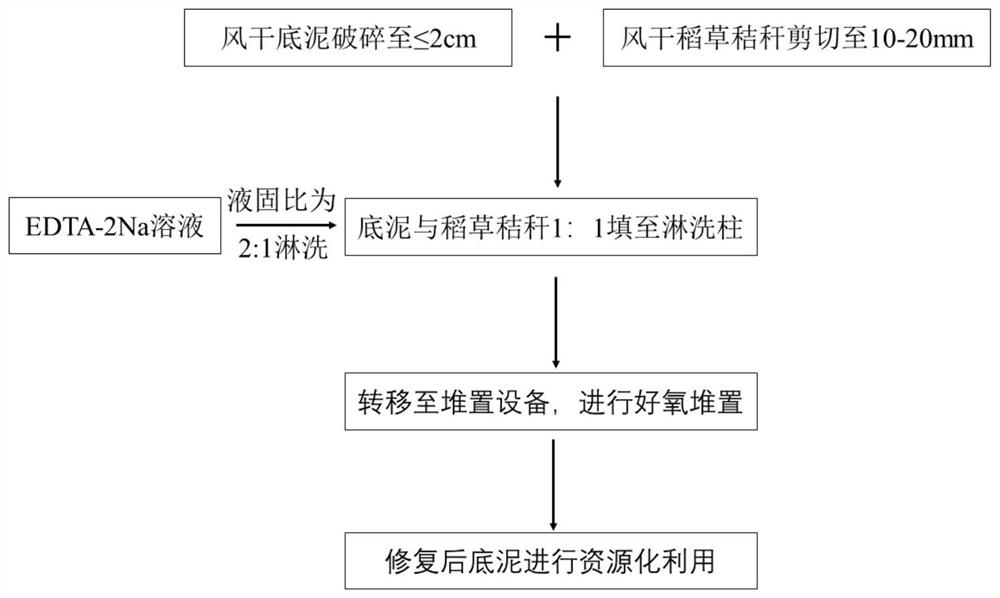

[0037] A method for combined restoration of heavy metal-contaminated sediment by leaching and stacking, such as figure 1 shown, including the following steps:

[0038] S1. Collect the surface sediment of the Changsha section of the Xiangjiang River, air-dry it at room temperature, remove impurities, grind and crush it, and pass through a 10-mesh sieve to obtain sediment with a particle size ≤ 2 cm. The rice straw (commercially purchased) is air-dried and ground (cut) to a length of 10-20 mm. The basic physical and chemical properties and heavy metal content of the sediment and rice straw are shown in Table 1.

[0039] Table 1 Basic physical and chemical properties of sediment and rice straw

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com