Equipment suitable for online repair of main pump flange sealing surface

A flange sealing and equipment technology, used in metal processing equipment, metal processing mechanical parts, maintenance and safety accessories, etc., can solve the problem of not having special on-site repair equipment, and it is difficult to ensure the smooth repair of the flange sealing surface of the main pump casing. Implementation and other issues, to achieve the effect of automatic and rapid measurement and processing supplement, reducing on-site foreign matter and processing surface quality, and adjustable processing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

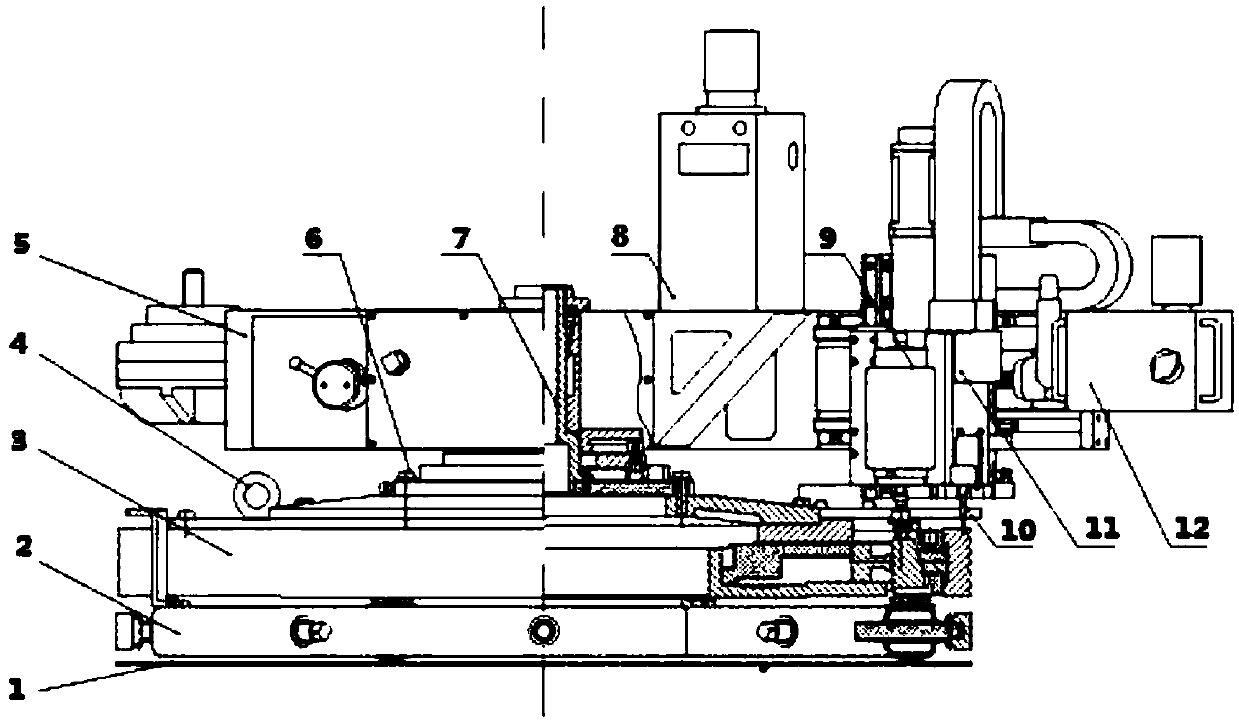

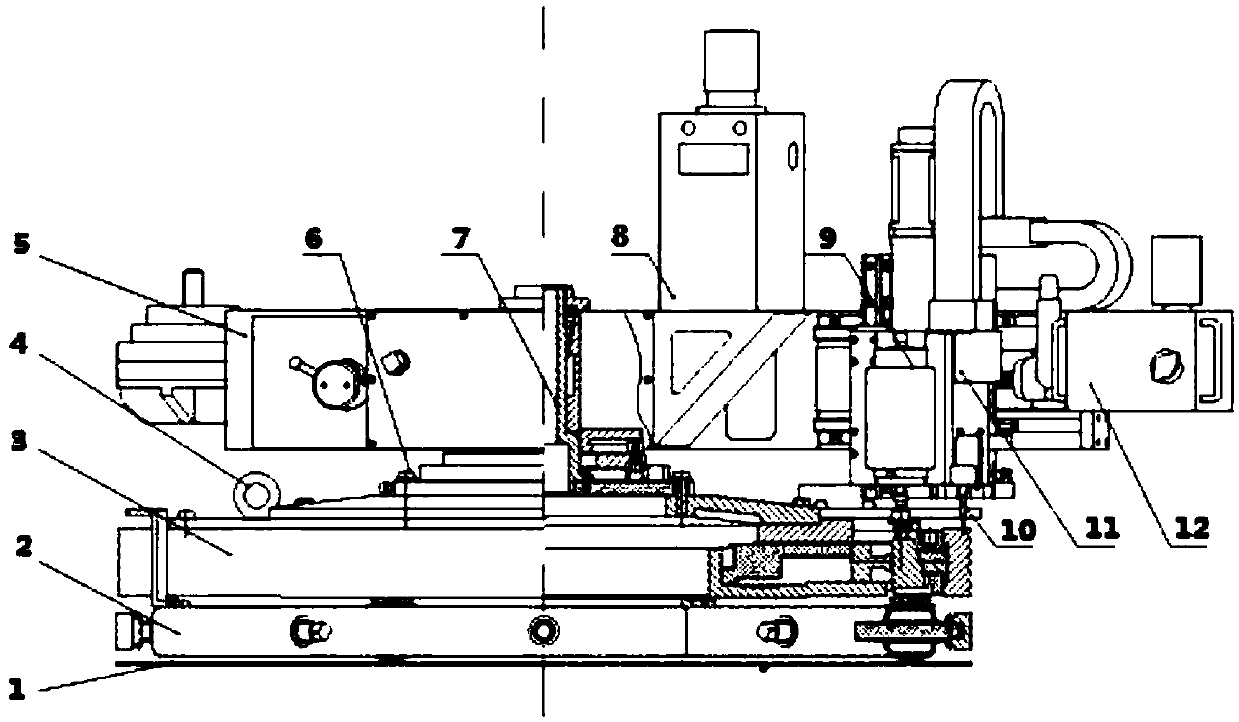

[0013] The invention discloses an on-site on-site repair system for the flange sealing surface of a main pump of a nuclear power plant, which mainly includes four parts: a remote console, a main control device, a monitoring device, and a repair device. After the system is assembled and debugged, the main control device, the repair device and the The detection device is arranged inside the space of the pump room, and the remote control console is arranged outside the space of the pump room for remote monitoring and control, so as to reduce the radiation exposure of the operators.

[0014] The remote console is a mobile control platform, which is connected to the main control device through a data cable, and receives the data information fed back by the main control device in real time and sends control instructions. It is mainly used for status monitoring and safety emergency operations during the stable processing of the repair device. The remote console is equipped with an ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com