Aircraft long rod part assembling equipment and using method thereof

A technology for parts assembly and aircraft assembly, applied in the direction of hand-held tools, manufacturing tools, etc., can solve the problem that if the parts cannot be lifted, one end of the parts may be tilted and rolled to the ground, which will affect the personal safety of the aircraft production cycle and installation workers. Safety impact and other issues, to achieve the effect of novel mechanical structure, clear division, and prevent industrial accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

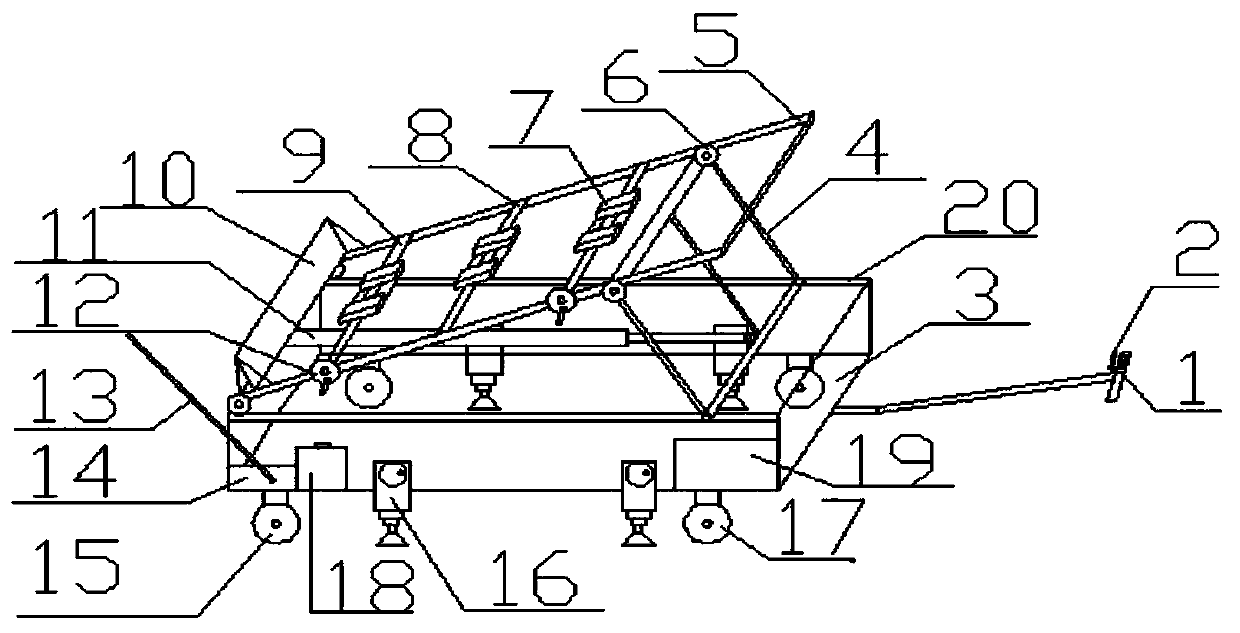

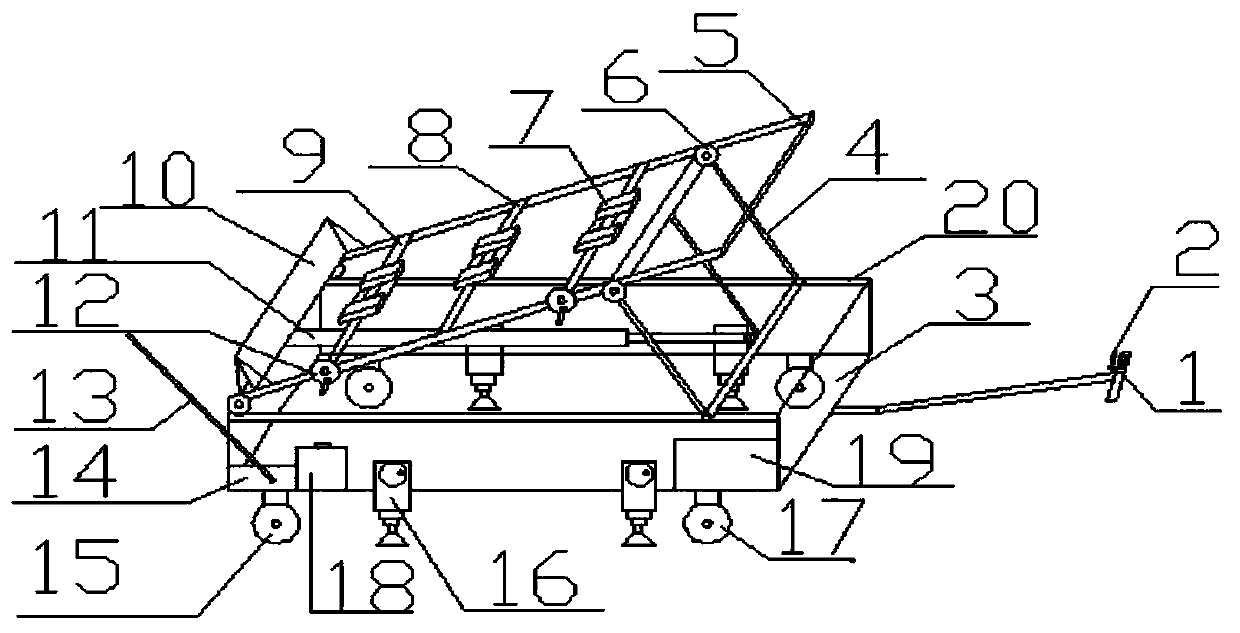

[0025] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0026] Such as figure 1 Shown, a kind of aircraft long pole parts assembly equipment, comprises automatic consignment drive system, hydraulic drive system and mechanical adjustment system; Automatic consignment drive system comprises universal handle 1, driving handle 2, electric wheel 15, universal roller 17 and The electric control device 19 is used to provide the propulsion force; the hydraulic drive system includes the base bracket 3, the sliding support device 4, the hydraulic strut device 11, the pressure rod 13, the manual hydraulic pump 14, the oil tank 18 and the grooved slide rail 20, It is used to lift one end of long rod parts and adjust them in the inclination angle and up and down direction, so that long rod parts can reach the designated installation position, replacing the installation inconvenience ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com