Material lifting device for construction industry

An industry and material technology, applied in the field of material lifting devices in the construction industry, can solve the problems of user effort, poor stability of lifting sliders, high failure rate, etc., and achieve labor-saving use, improve shock absorption and buffering effects, and increase transmission ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

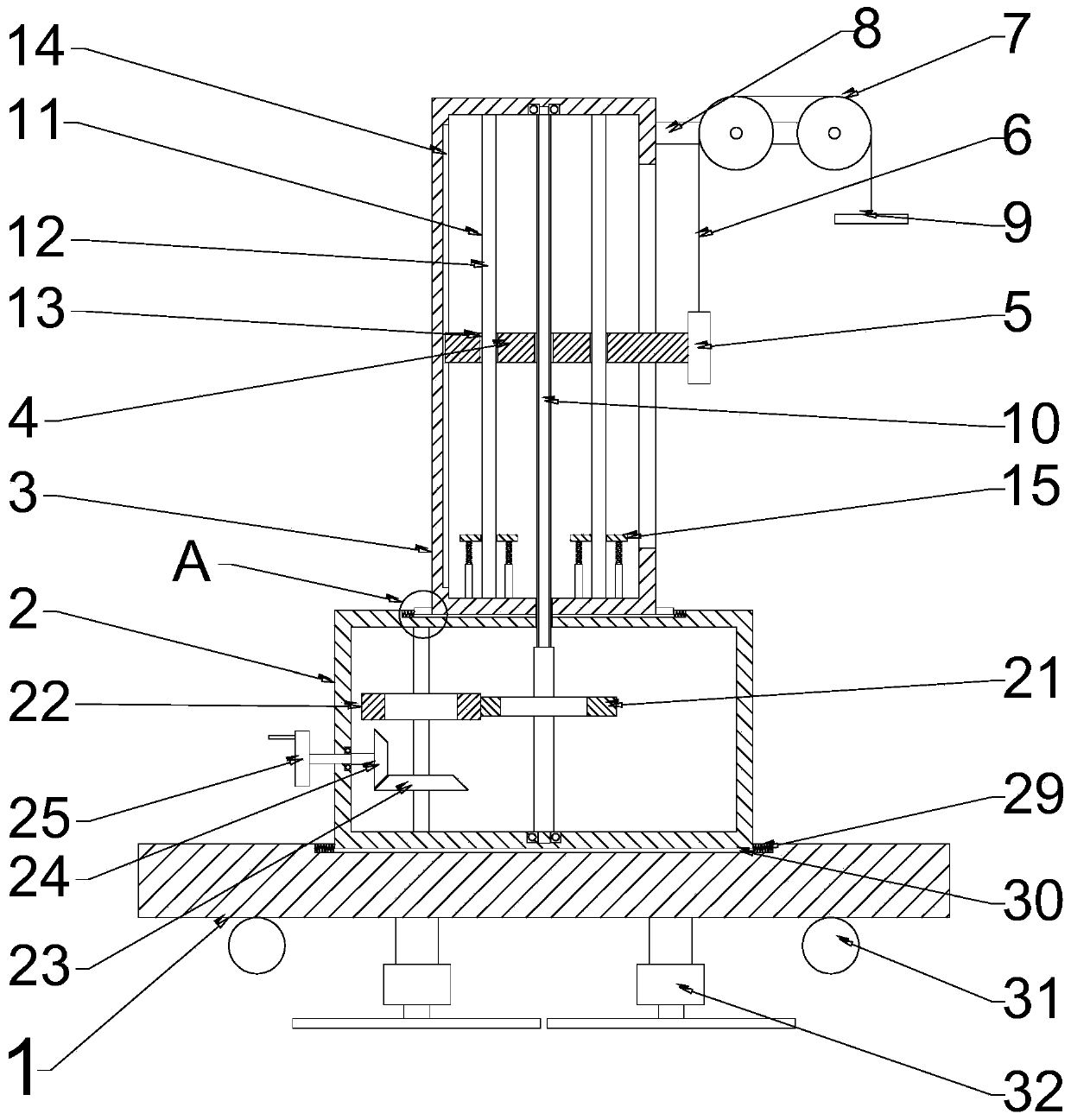

[0019] see figure 1 with figure 2 , a material lifting device for the construction industry, comprising a base 1, a transmission box 2, a control box 3, a lifting block 4, a connecting block 5, a steel wire rope 6, a pulley 7, a pulley frame 8 and a hook 9, the base 1 is provided with The transmission box 2, the control box 3 is arranged above the transmission box 2, the lifting block 4 is arranged inside the control box 3, and the connecting block 5 is welded and fixed on the right end of the lifting block 4, so The upper end of the connection block 5 is welded and fixed with the steel wire rope 6, the steel wire rope 6 is installed on the pulley 7 and the end is connected with the hook 9, and the pulley 7 is bolted on the pulley frame 8; the lifting The block 4 is slidably installed in the chute 14, and the chute 14 is opened on the inner wall of the left side of the control box 3, and the center of the lifting block 4 is threaded with a rotating shaft 10, and the upper en...

Embodiment 2

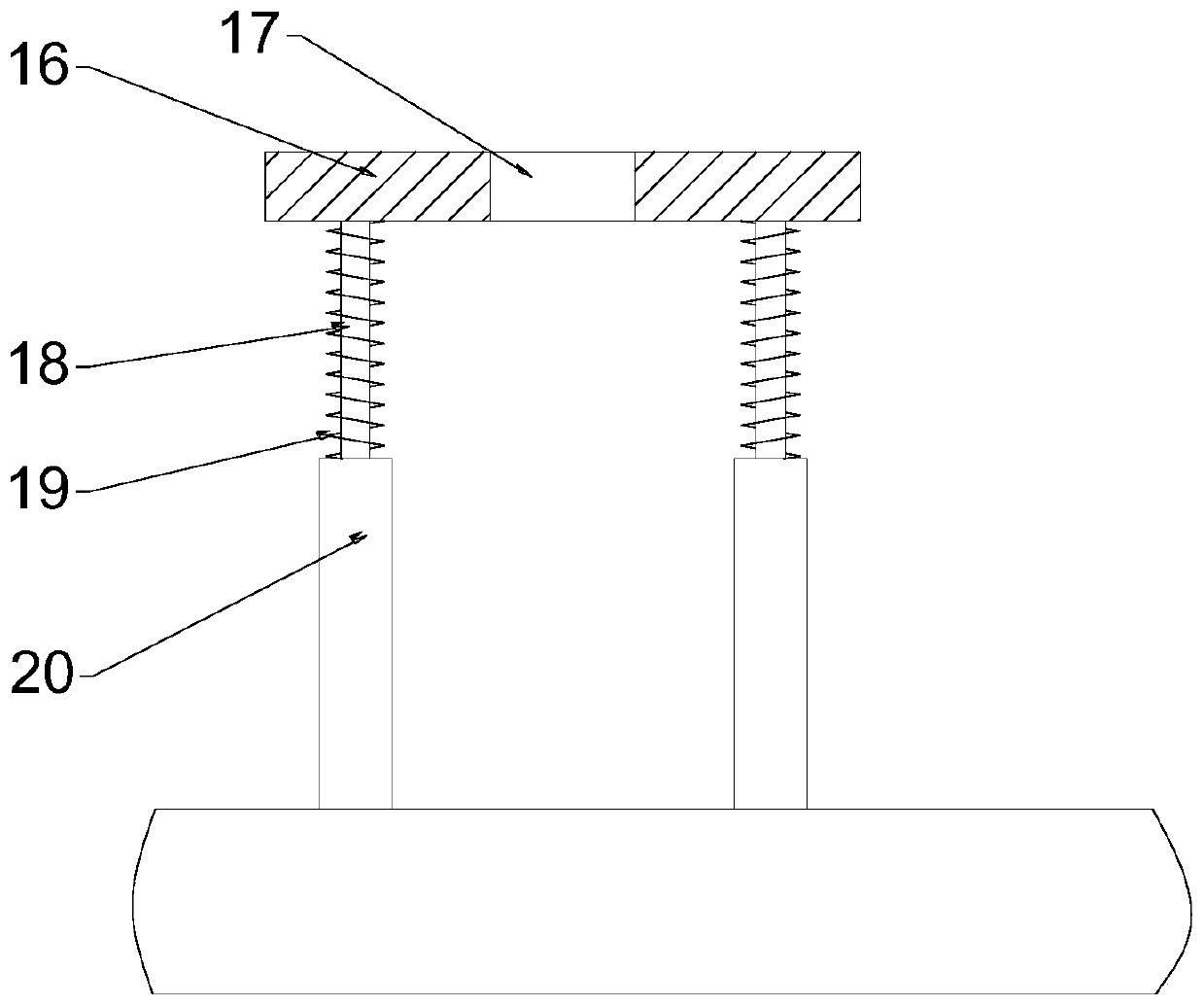

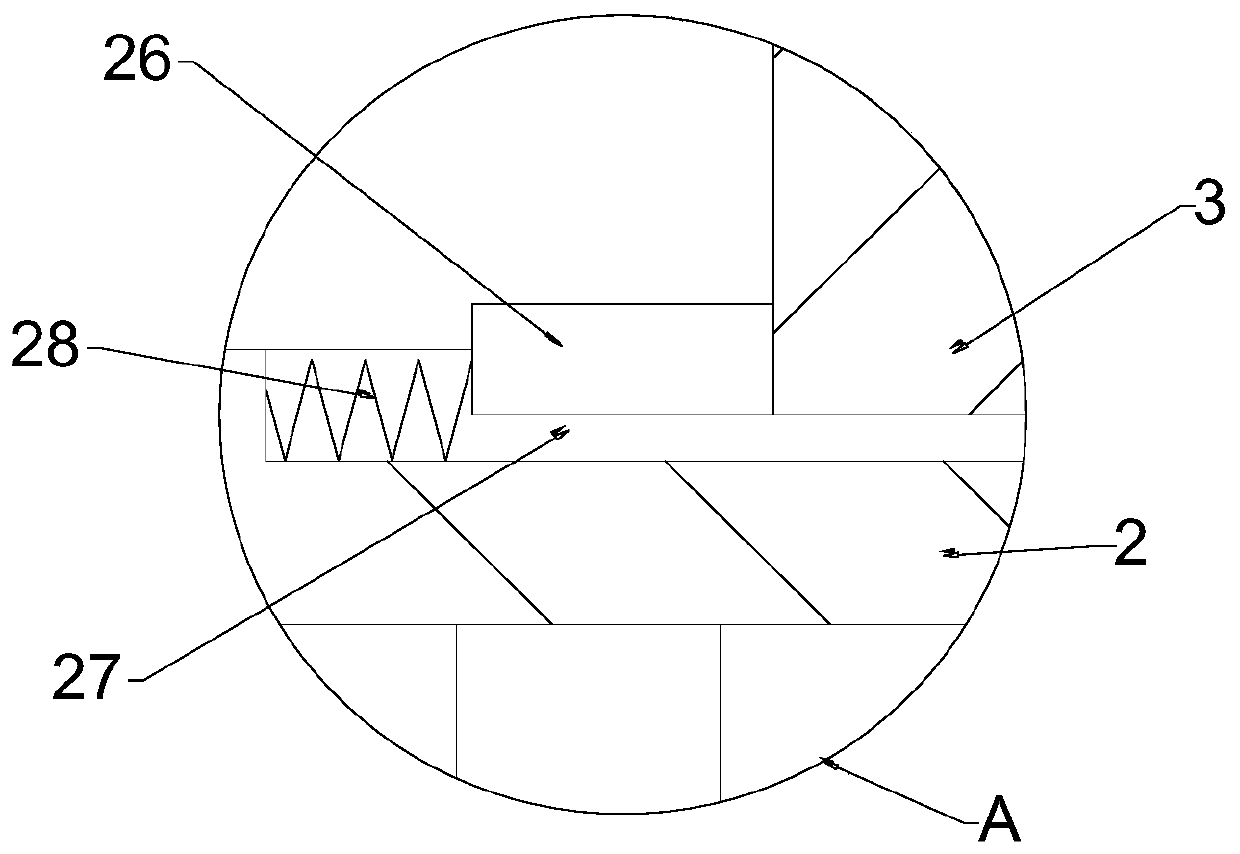

[0021] see figure 1 with image 3 , the left and right sides of the bottom of the control box 3 are welded with stoppers 26, and the stoppers 26 are slidably installed in the notch 27, and the notch 27 is opened on the top of the transmission box 2, and the notch 27 A spring B28 is also placed, which can greatly improve the buffer performance between the transmission box 2 and the control box 3; On the upper end surface, a spring C29 is also placed in the positioning groove 30 to play a buffering and shock-absorbing effect; the bottom bolt of the base 1 is fixed with a universal wheel 31 and a hydraulic support seat 32 .

[0022] The working principle of the present invention is: the material is hung on the hook 9, and then the worker lifts the material by rotating the turntable shaft 25. Since two pairs of gears are used in the transmission box 2, the transmission ratio of the device is greatly improved. It makes it more convenient and labor-saving for workers to turn the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com