Black garlic fermentation machine

A technology of fermenter and black garlic, which is applied in bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical instruments, etc., can solve the problems of low reliability and complicated operation of black garlic, and achieve The effect of reducing adverse effects and high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further explain the technical means and functions adopted by this application to achieve the predetermined purpose, the specific implementation, structure, features and functions according to this application will be described in detail below in conjunction with the drawings and preferred embodiments. In the following description, different "one embodiment" or "embodiment" do not necessarily refer to the same embodiment. Furthermore, the particular features, structures, or characteristics of one or more embodiments may be combined in any suitable manner.

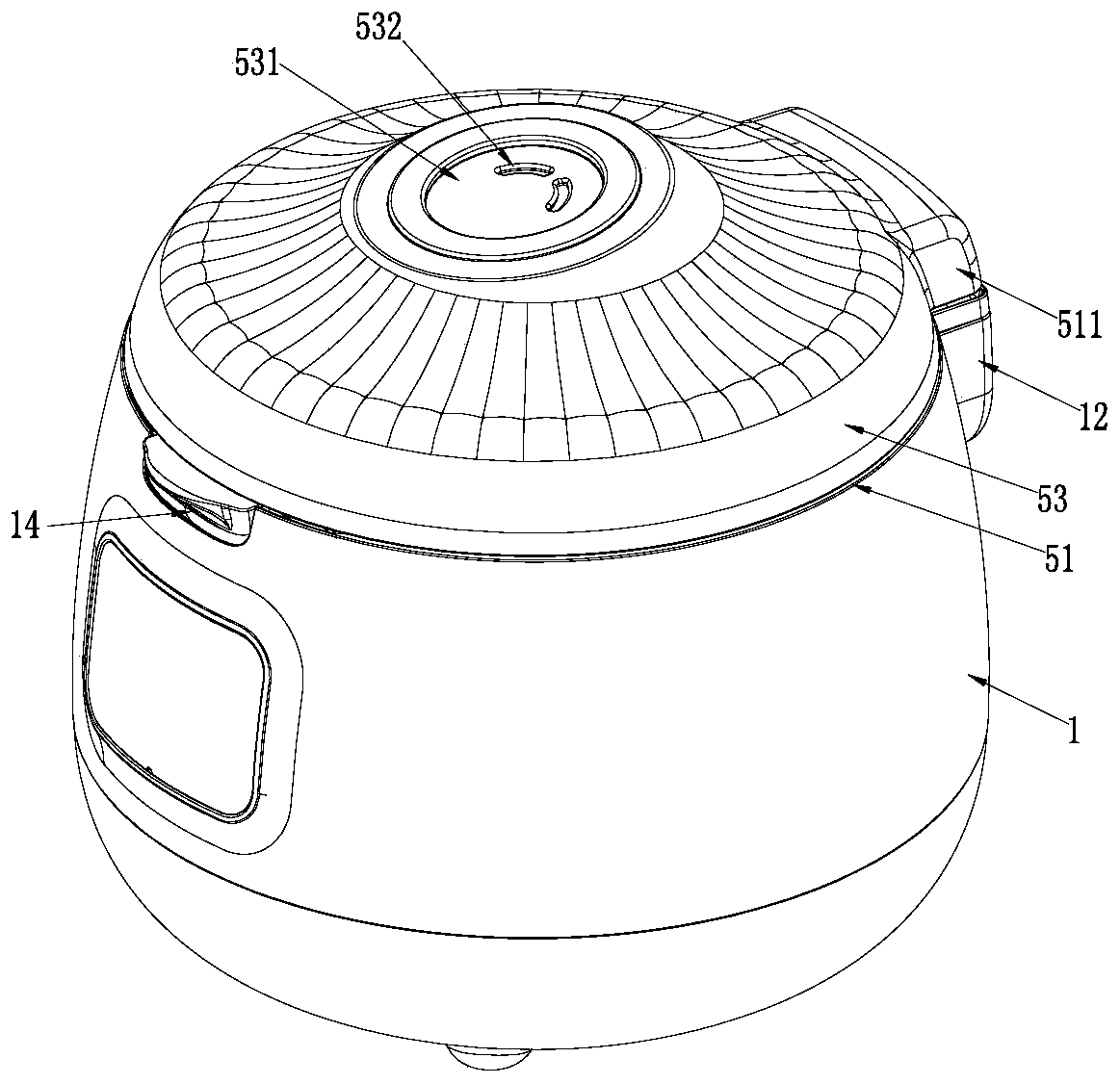

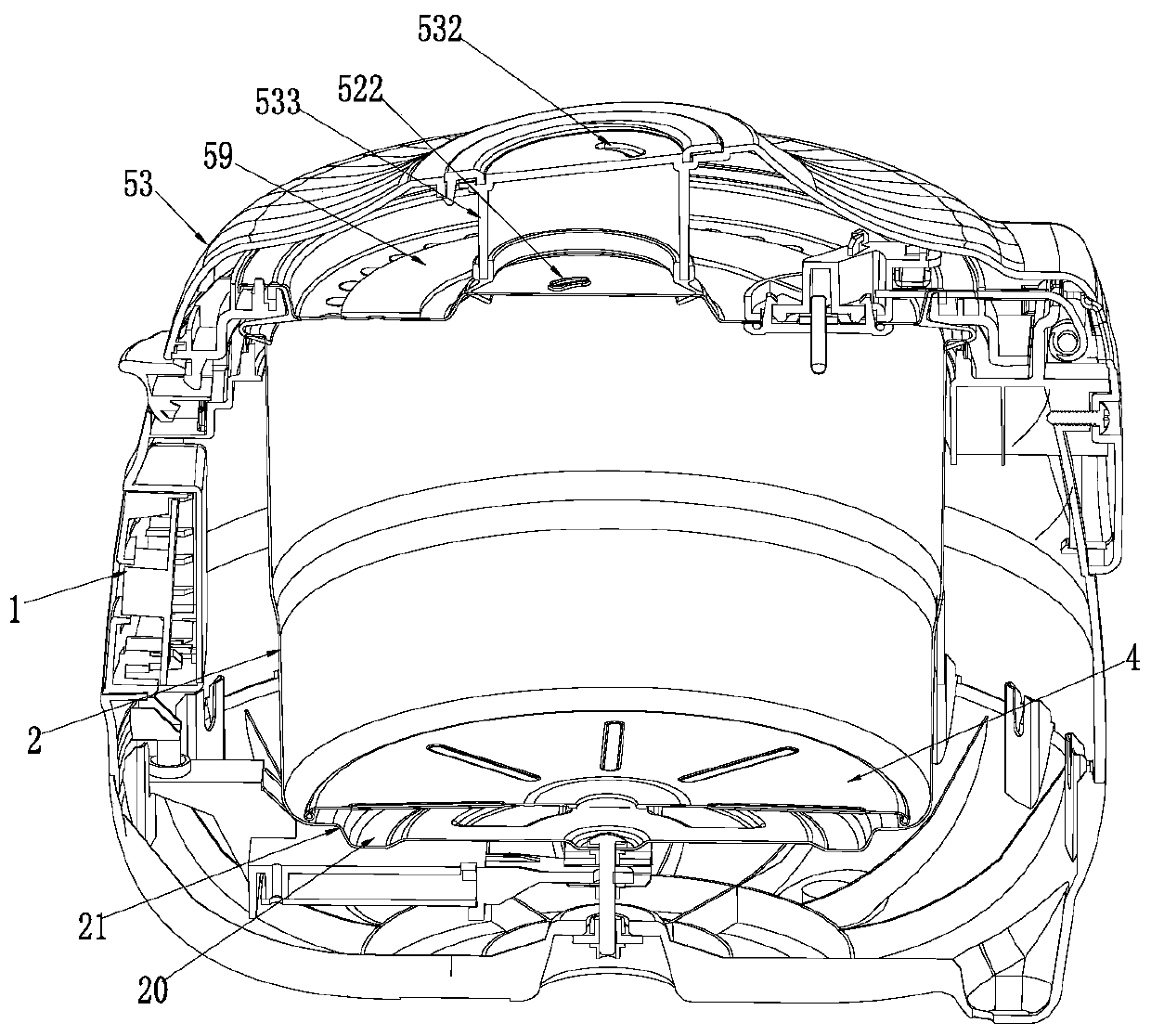

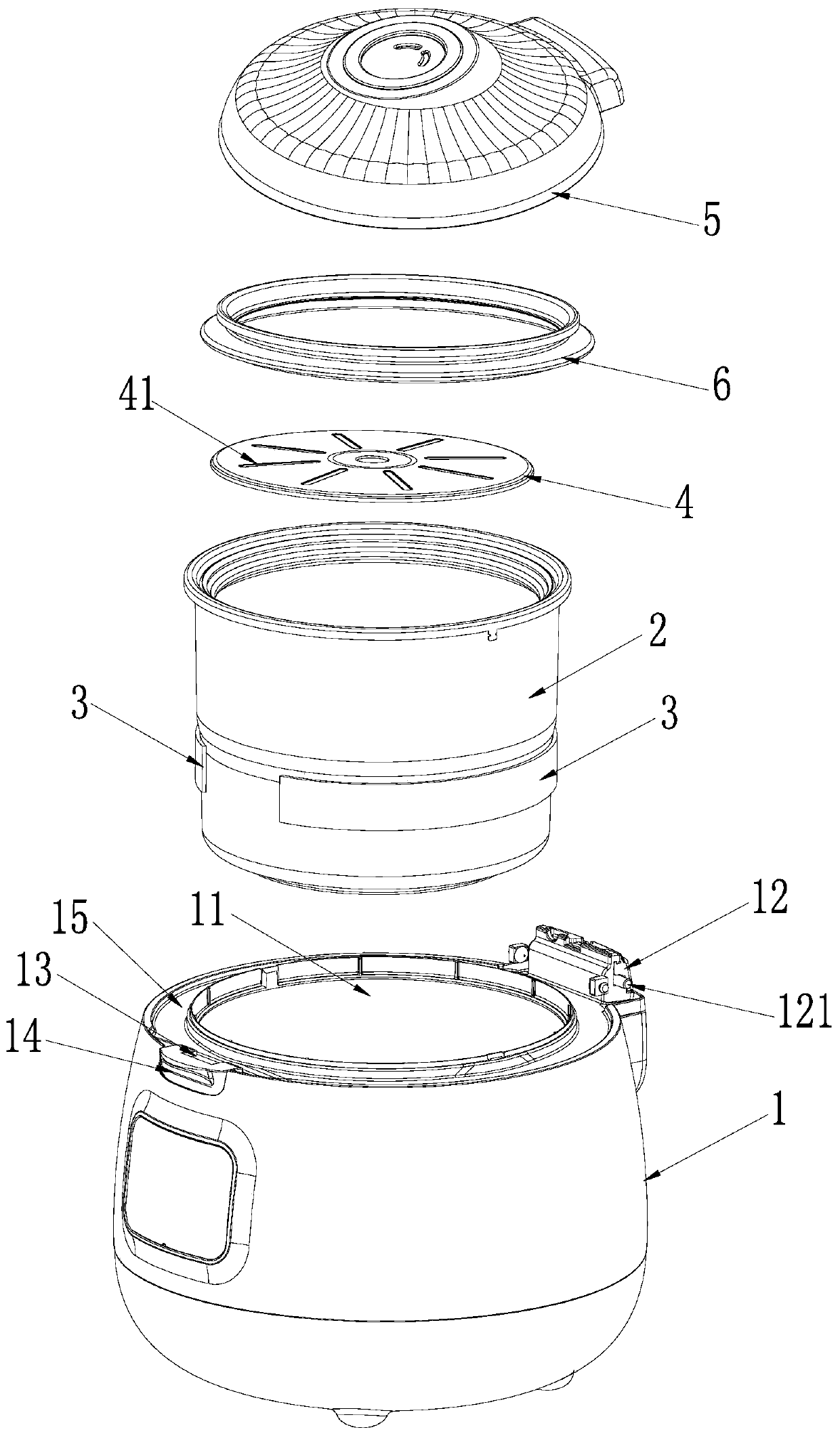

[0026] combine Figure 1-Figure 3 As shown, the present invention discloses a black garlic fermenter, which includes a body 1 with an accommodation cavity 11, a fermentation pot 2 placed in the accommodation cavity 11, a heating device arranged in contact with the fermentation pot 2, and a cover on the body 1 is used to seal the fermenter 2 in the accommodating cavity 11. The heating device is set away fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com