Split type easy-to-clean chute for highway engineering

A split-type, easy-to-clean technology, applied in the direction of roads, roads, cleaning of sewer pipes, etc., can solve the problems of fixed structure, inconvenient adjustment of activities, unfavorable drainage use, lack of sewage discharge mechanisms, etc., to avoid blockage, facilitate cleaning, and quickly discharge sewage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

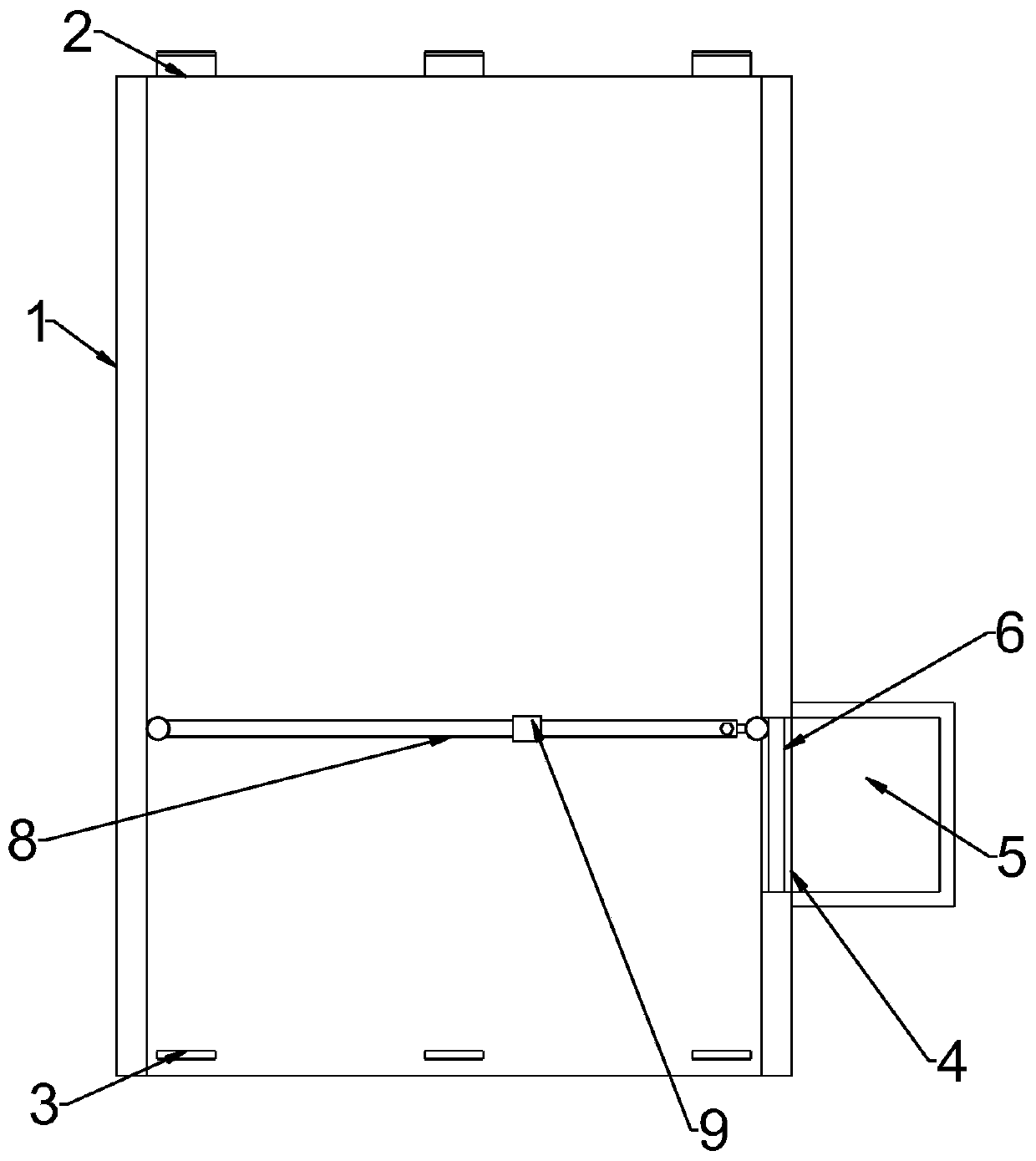

Method used

Image

Examples

Embodiment 2

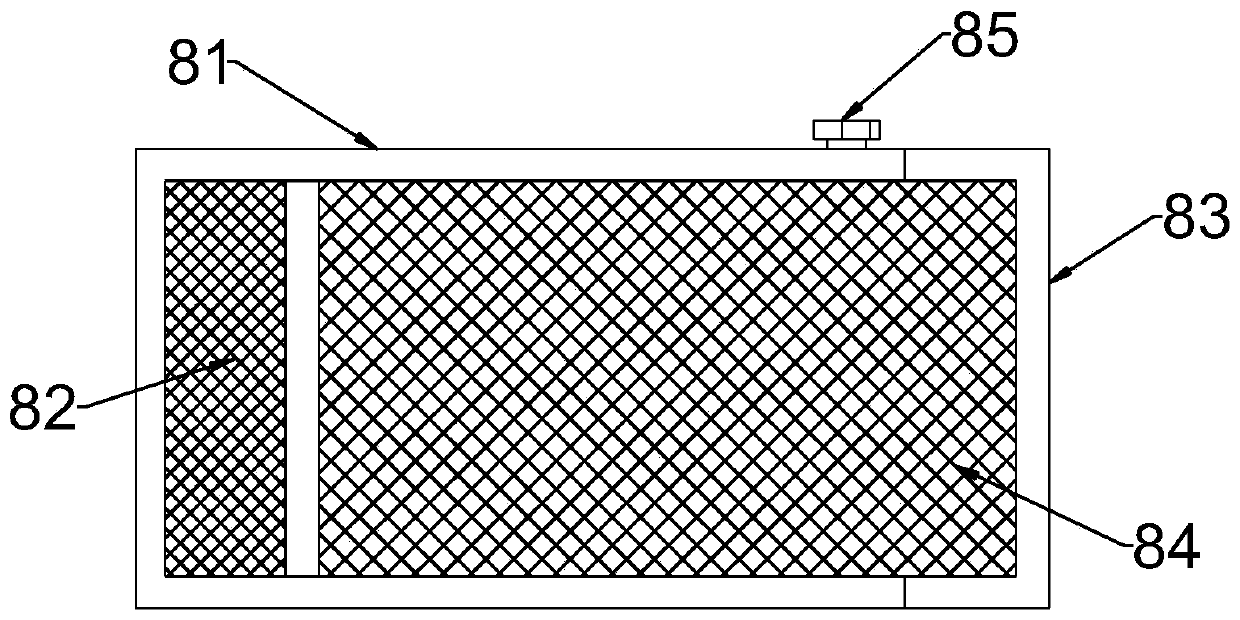

[0025] see Figure 4 , in an embodiment of the present invention, a split-type easy-to-clean jet trough for highway engineering, on the basis of Embodiment 1, the cleaning brush 9 includes a bottom plate 91 that is slidably fitted and arranged on the upper end of the grille 8, and a sliding connection arrangement The sliding brush 92 and the sliding protrusion 94 at the lower end of the base plate 91 and the rotating handle 95 arranged at the upper end of the base plate 91 are rotationally connected. The sliding brushes 92 are welded at the lower end of the sliding protrusions 94, densely covered bristles are symmetrically arranged between the sliding brushes 92, and limit rollers are symmetrically connected between the upper parts of the sliding brushes 92. 93 , a connecting cable 96 is connected between the upper parts of the sliding protrusions 94 , and the connecting cable 96 runs through the lower end of the turning handle 95 . Turning the turning handle 95 can wind the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com