Gas burner

A gas burner and gas technology, which is applied to burners, burners, gas fuel burners, etc., can solve the problems of affecting the combustion performance of the burner, insufficient mixing of gas and air, and uneven gas flow, so as to avoid gas flow. uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

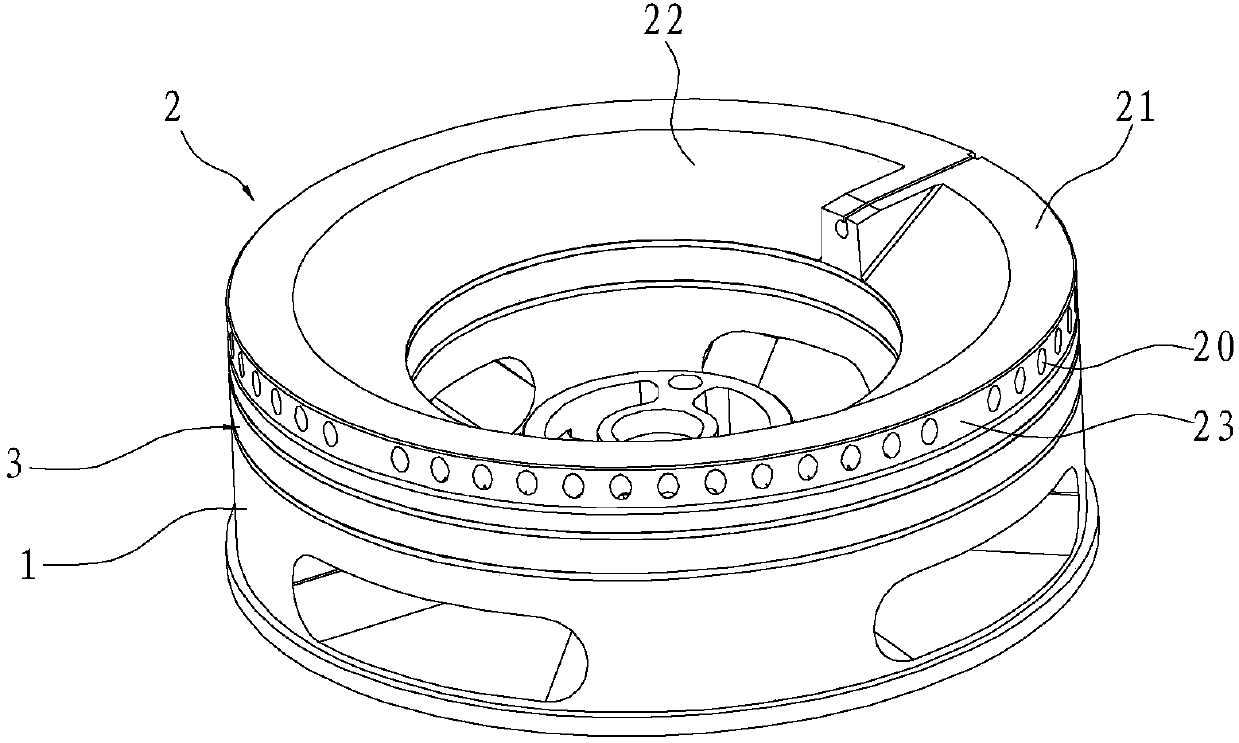

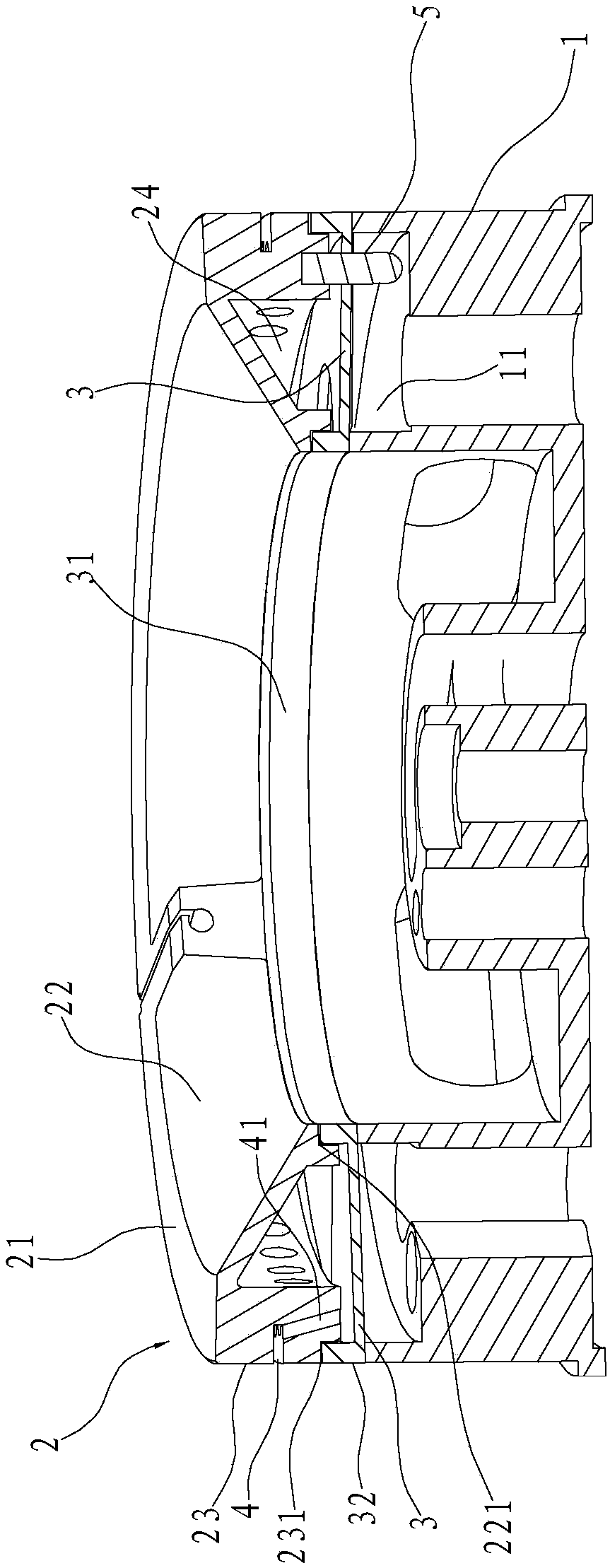

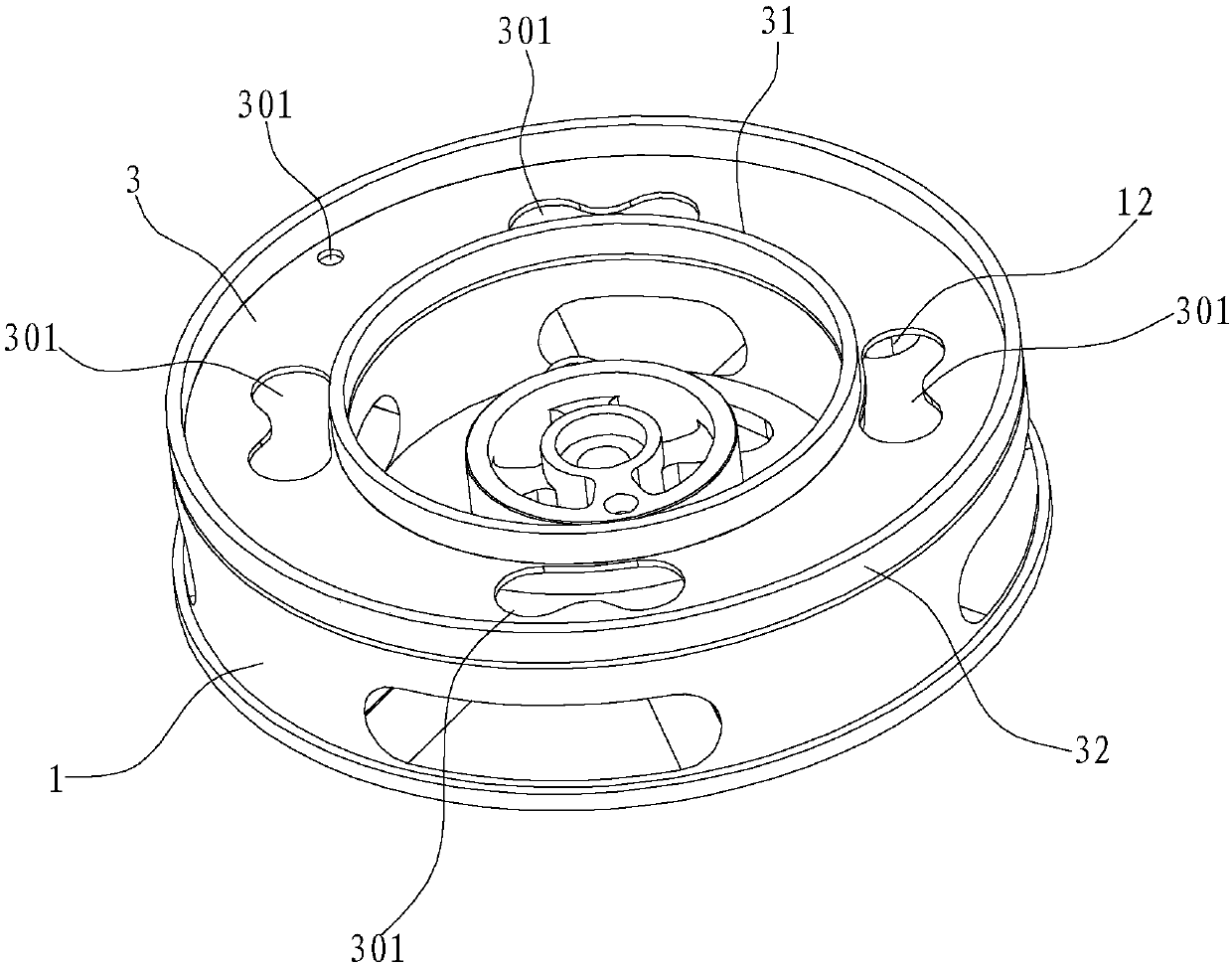

[0026] Such as Figure 1~5 As shown, a gas burner includes a gas mixing chamber 1 and an outer ring fire cover. The top of the gas mixing chamber 1 is provided with an annular cavity 11 opening upwards, and the bottom wall of the annular cavity 11 is provided with circumferential intervals. There is a gas outlet 12, and the above-mentioned outer ring fire cover is arranged on the annular cavity 11, and the outer ring fire cover includes an annular fire cover body 2, and the fire cover body 2 includes an annular top wall 21 and an inner wall of the top wall 21. The inner ring wall 22 and the outer ring wall 23 extending vertically or obliquely downwards from the outer edge respectively, the top wall 21, the inner ring wall 22 and the outer ring wall 23 are surrounded to form an air mixing chamber 24, the outer ring A fire hole 20 communicating with the gas mixing chamber 24 is provided on the wall 23 .

[0027] Further, an annular interlayer 3 is arranged circumferentially bet...

Embodiment 2

[0032] Such as Figure 6 As shown, the difference from Embodiment 1 is that the bottom surface of the interlayer 3 in this embodiment protrudes upwards at the positions opposite to the gas outlets 12 to form impact grooves 33, and the impact grooves 33 have a round surface, so that The flow of gas on the lower surface of the interlayer 3 is made more gentle, so that the mixing effect of gas and air is better. Preferably, the cross section of the impact groove 33 is arc-shaped, so that the groove surface of the impact groove 33 can better exert the Coanda effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com