Energy gathering assembly used for gas stove

A gas stove and energy-gathering technology, applied in the field of gas stoves, can solve the problems of poor energy-gathering effect, excessive heat dissipation, and large surface area, and achieve the effects of reducing heat loss, reducing heat conduction, and promoting combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

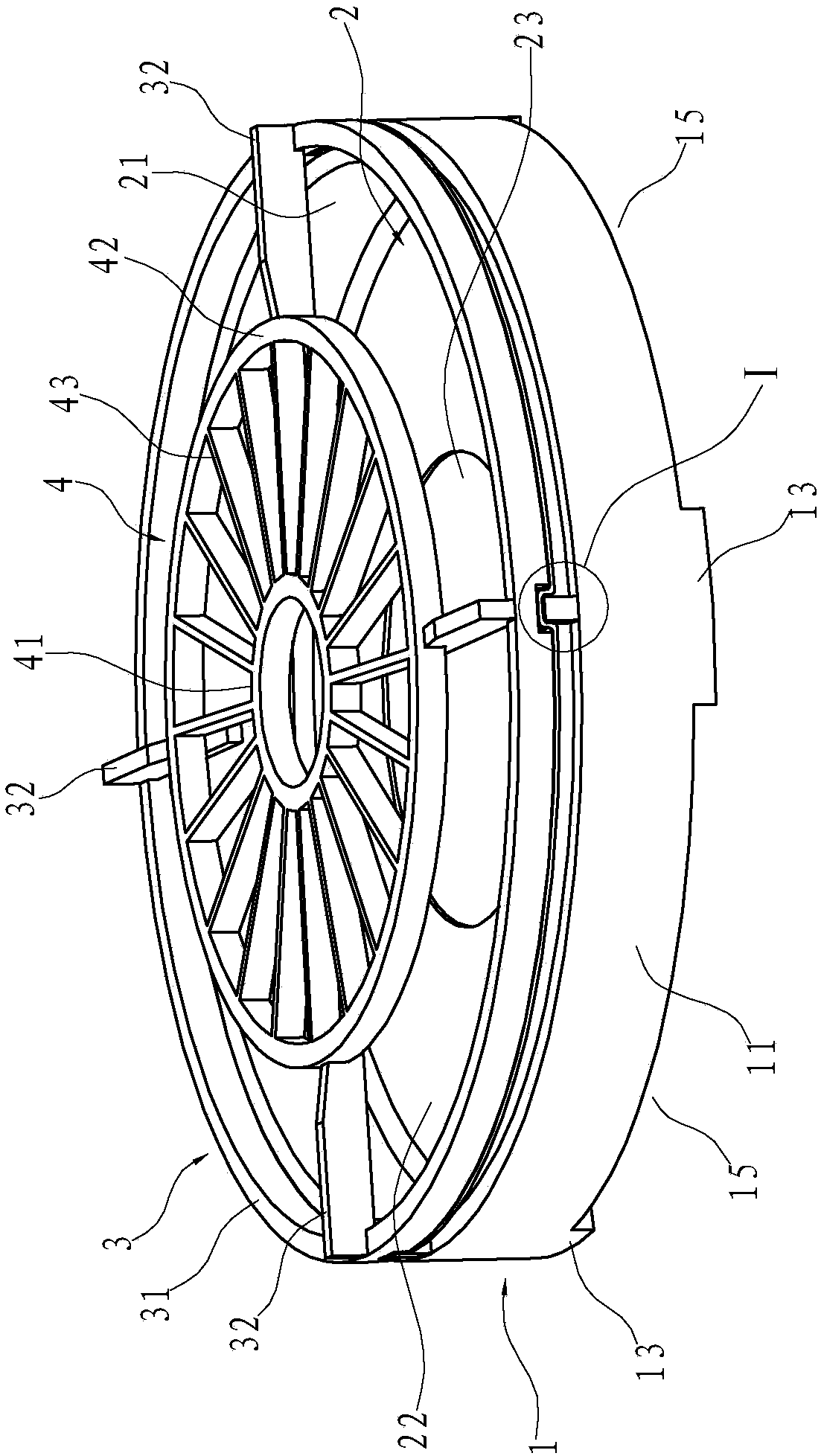

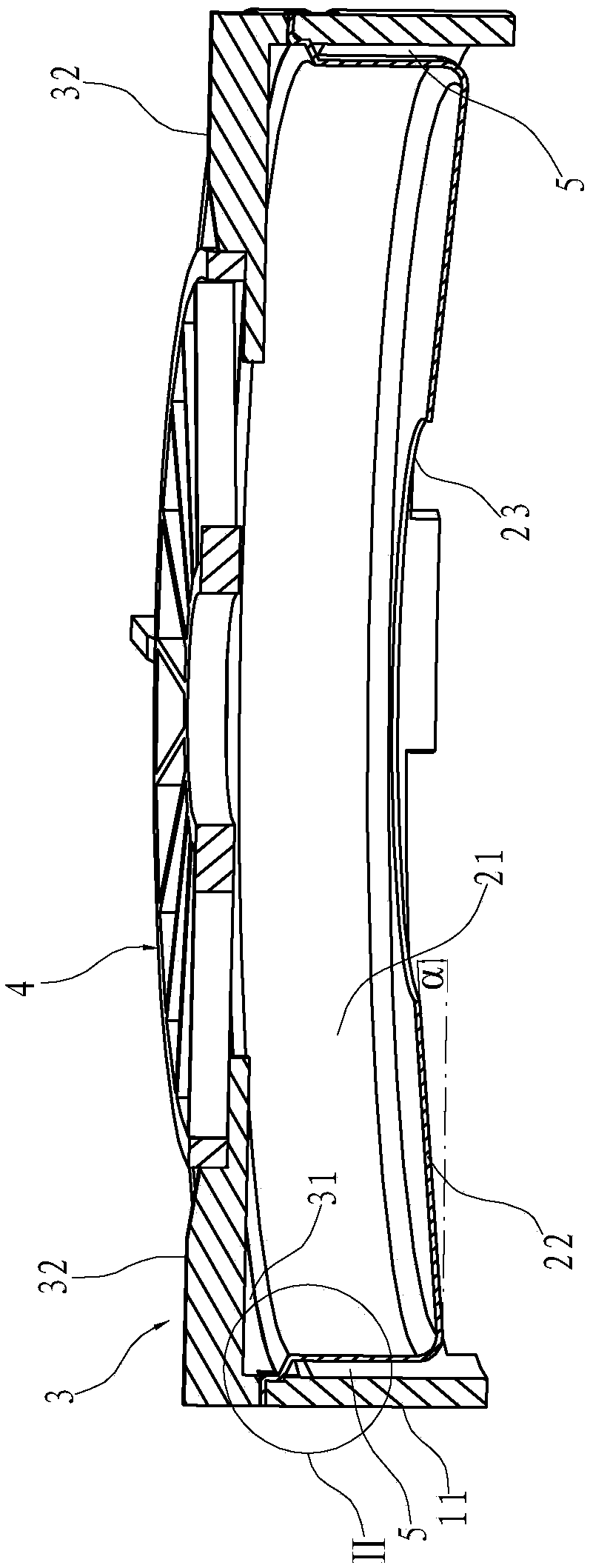

[0024] Such as Figure 1~5 As shown, an energy-gathering assembly for a gas stove includes an inner ring 2, an outer ring 1, a pot support 3, and a heat-collecting fin plate 4. The components are cleaned, wherein the outer ring 1 can support the above-mentioned inner ring 2, pot support 3 and heat collecting fin plate 4.

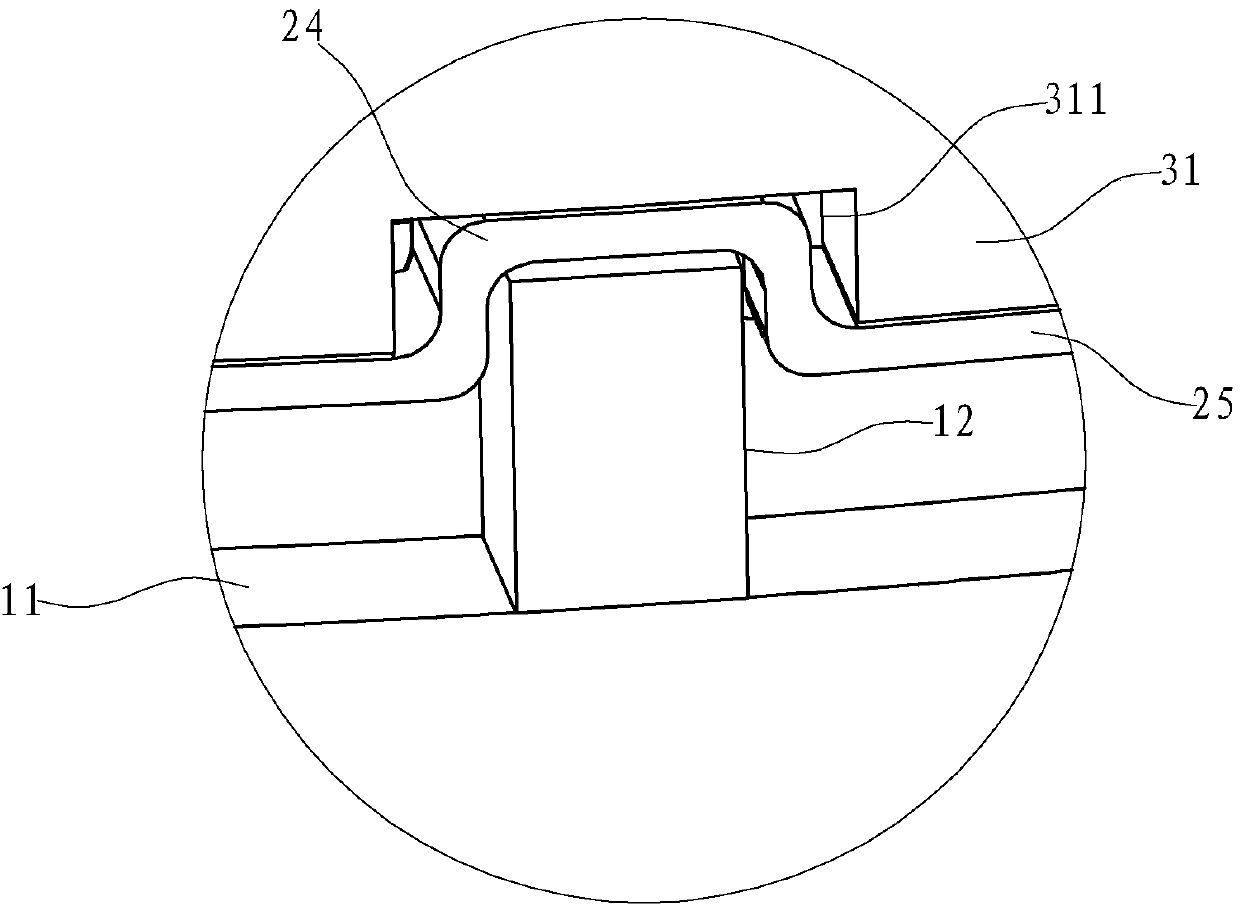

[0025] The above-mentioned outer ring 1 has a vertically extending first annular wall 11, the top edge of the first annular wall 11 is provided with vertically upwardly extending limiting protrusions 12 at intervals along the circumferential direction, and the bottom edge of the first annular wall 11 is circumferentially spaced. Support pads 14 are arranged at intervals, and secondary air gaps 15 for secondary air to enter are formed between adjacent support pads 14 . In this embodiment, the above-mentioned limiting protrusions 12 and supporting pads 14 are four pieces, and they are arranged opposite to each other up and down. In this embodiment, setting t...

Embodiment 2

[0031] Such as Image 6 As shown, the difference from Embodiment 1 is that in this embodiment, the above-mentioned energy-gathering gap 5 is filled with thermal insulation material 6 with a thermal conductivity lower than that of air. heat loss. Preferably, the thermal insulation material 6 is thermal insulation cotton.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com