A Humidifying Baseboard Electric Heater

A baseboard heating and heating technology, applied in the field of baseboard heating, can solve the problems of increasing air humidity, inconvenient fixing, inconvenient air filtration, etc., and achieve the effect of increasing humidity and increasing filtering function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

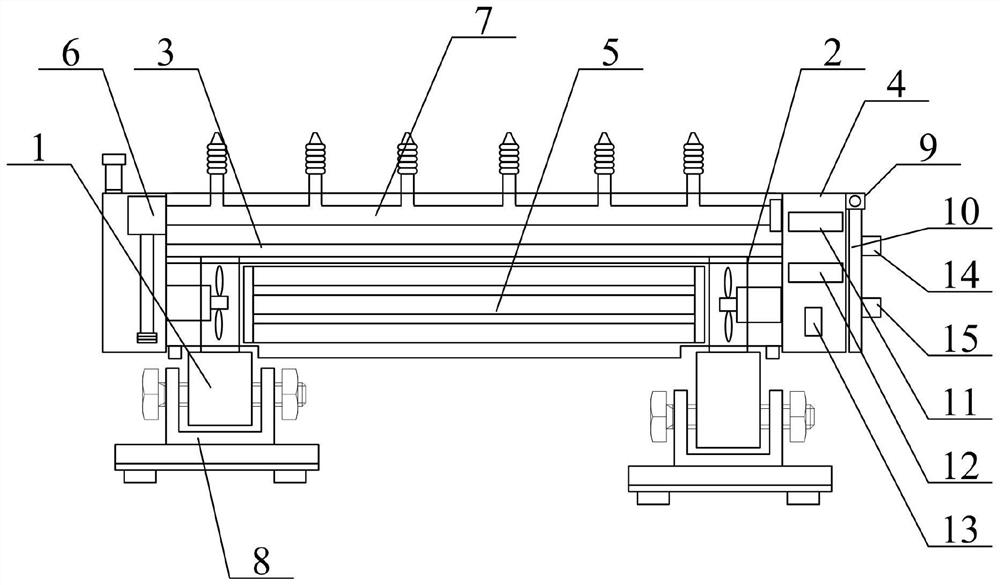

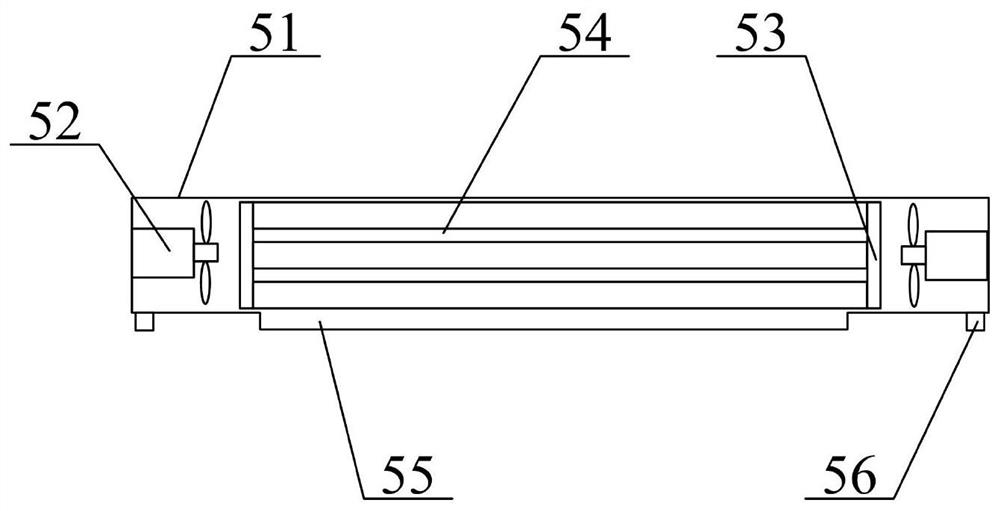

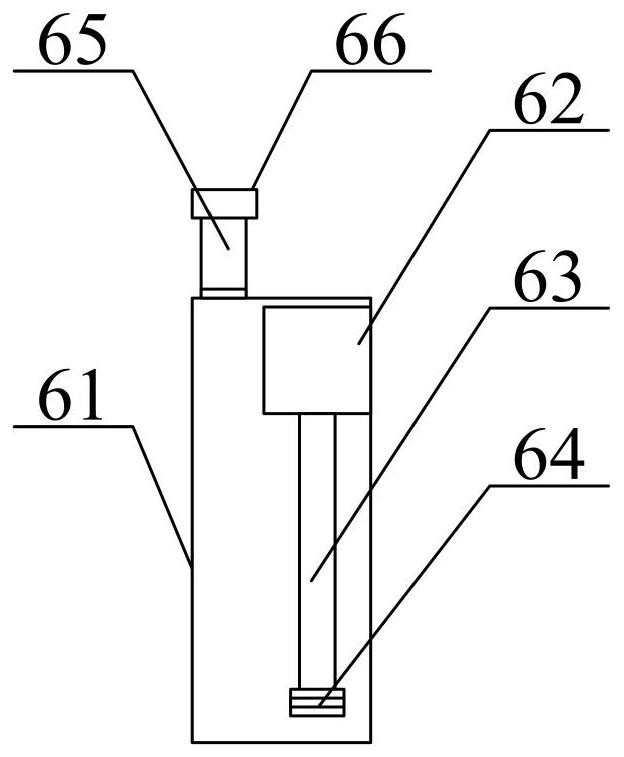

[0046] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, a baseboard electric heater that can be humidified includes a connecting seat 1, a first fixed pipe 2, a support plate 3, a control box 4, a filter heat dissipation bucket structure 5, an observable filter water injection tank structure 6, and can be rotated Spray pipe structure 7, rotatable fixed seat structure 8, U-shaped seat 9, rotating rod 10, PLC11, display screen 12, power switch 13, temperature sensor 14 and humidity sensor 15, the lower ends of the first fixed pipe 2 are respectively Welded on the upper end of the connecting seat 1; the upper ends of the first fixed pipe 2 are respectively welded on the left and right sides of the lower end of the support plate 3; the right end of the support plate 3 is welded on the upper left side of the control box 4; The filterable cooling barrel structure 5 is installed inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com