High-temperature and high-pressure hanging piece dynamic corrosion instrument

A high-temperature, high-pressure, corrosion instrument technology, applied in the direction of weather resistance/light resistance/corrosion resistance, instruments, scientific instruments, etc., can solve problems that affect mining production, corrosion damage, etc., and achieve the effect of prolonging the service life and avoiding failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

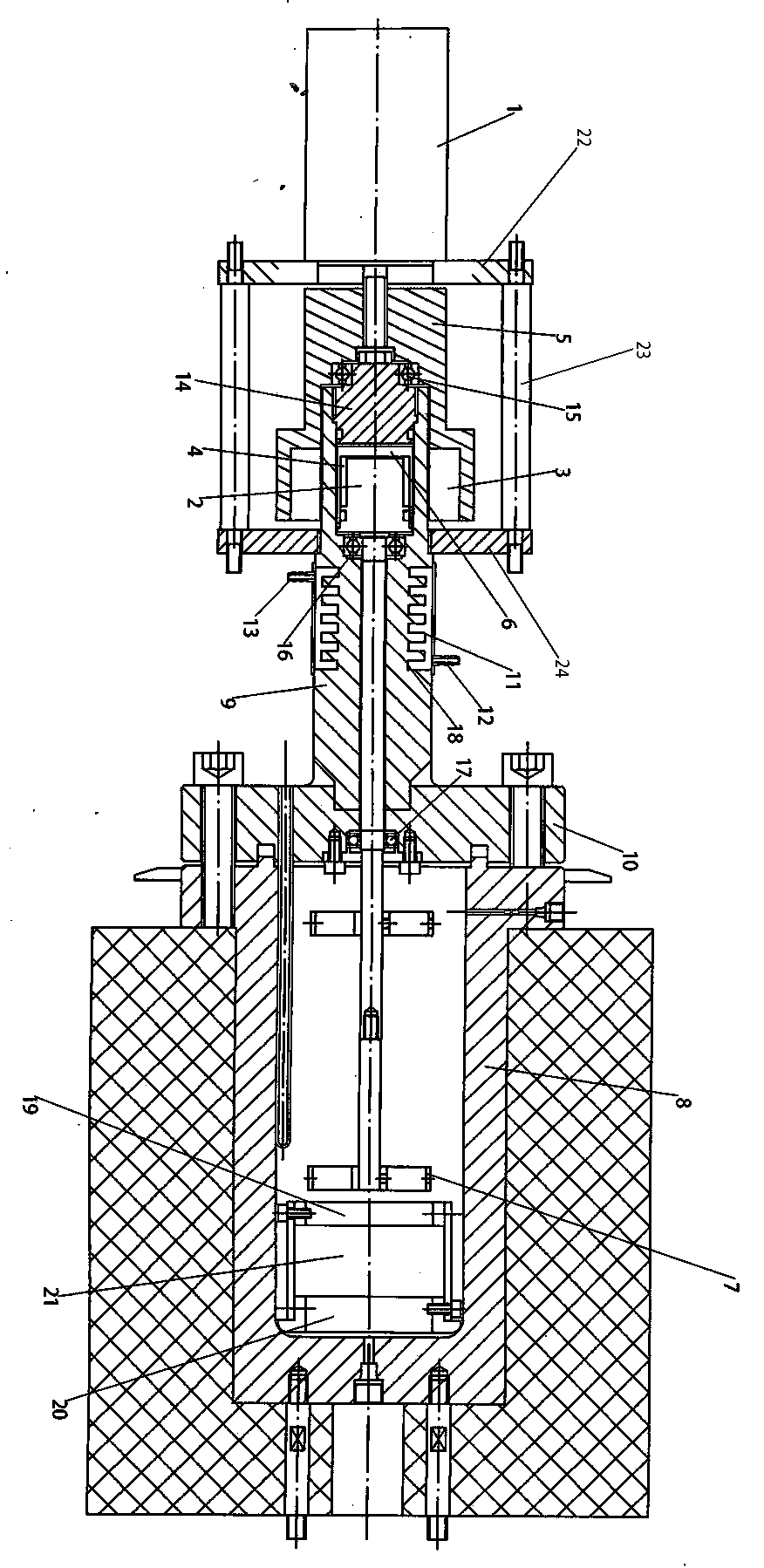

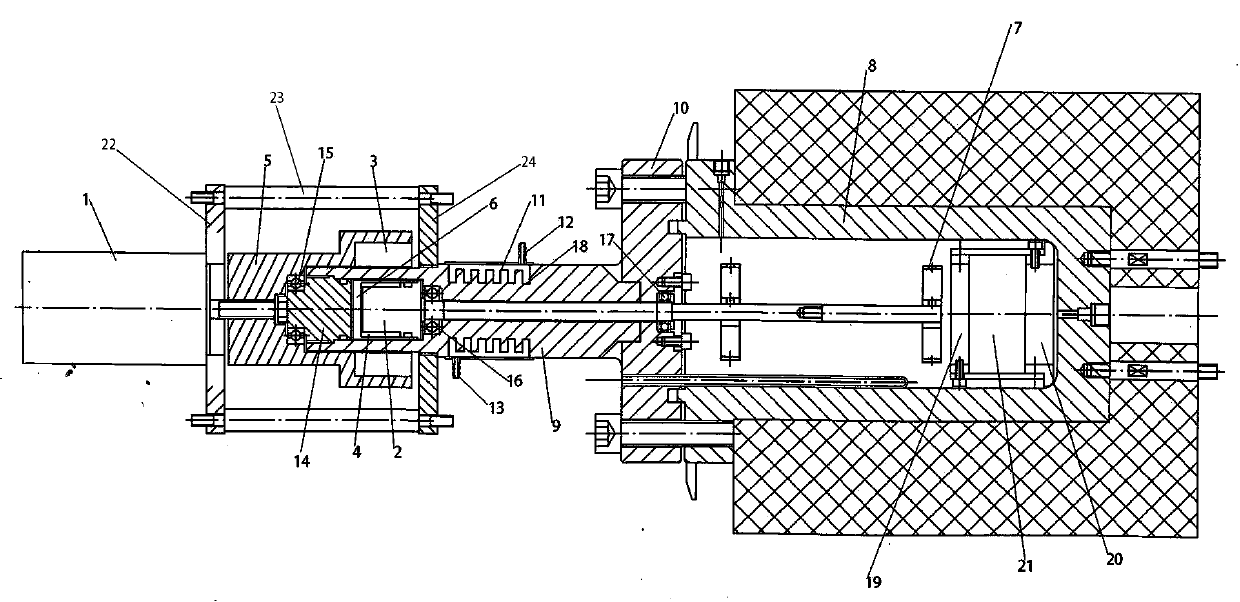

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0011] figure 1 Middle: stirring motor 1, stirring shaft 2, outer magnet 3, inner magnet 4, outer magnet seat 5, inner magnet seat 6, stirring paddle 7, kettle body 8, cover neck 9, cover body 10, cooling cavity 11, Water inlet 12, water outlet 13, plug 14, first bearing 15, second bearing 16, third bearing 17, fold 18, upper connecting plate 19, lower connecting plate 20, hanging piece sample 21, upper fixing plate 22 , support rod 23, lower fixed plate 24.

[0012] The high-temperature and high-pressure coupon corrosion tester is a small acid-resistant high-temperature and high-pressure reaction kettle. It uses the weight loss method to test the corrosion rate of the coupon in the acid solution without and with corrosion inhibitors, and is used to evaluate the corrosion ability of the acid solution. Corrosion resistance and the corrosion in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com