Cultivation substrate for ryegrass and preparation method thereof

A technology for cultivation substrate and ryegrass, which is applied in the field of cultivation substrate for ryegrass and its preparation, can solve the problem of less cultivation substrate for ryegrass, achieve the effects of high-quality and rapid growth, save economic resources, and improve the quality of pasture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A cultivation medium for ryegrass, which is made of the following components in volume percentage: 30-60% of decomposed mushroom residue fertilizer, 20% of vermiculite, 20% of perlite, and 0-30% of peat (Northeast peat); The decomposed mushroom dregs fertilizer is made of mushroom dregs, garden soil, bean dregs and microbial bacterial agents at a mass ratio of 750:0-800:0-400:1.

[0030] The preparation method of above-mentioned ryegrass cultivation substrate comprises the following steps:

[0031] Preparation of decomposed fungus dregs fertilizer: Mix the fungus dregs, garden soil, bean dregs and microbial agent (composting rapid decomposing agent of Yichun Qiang Microbial Technology Co., Ltd.) at a mass ratio of 750:0-800:0-400:1, and put it in barrels After stacking, pour water thoroughly, do not cover, turn over once a week, and continue for 40-50 days at an ambient temperature of 20-25°C, spread out and dry in the sun;

[0032] Among them, both the fungus residue ...

Embodiment 2

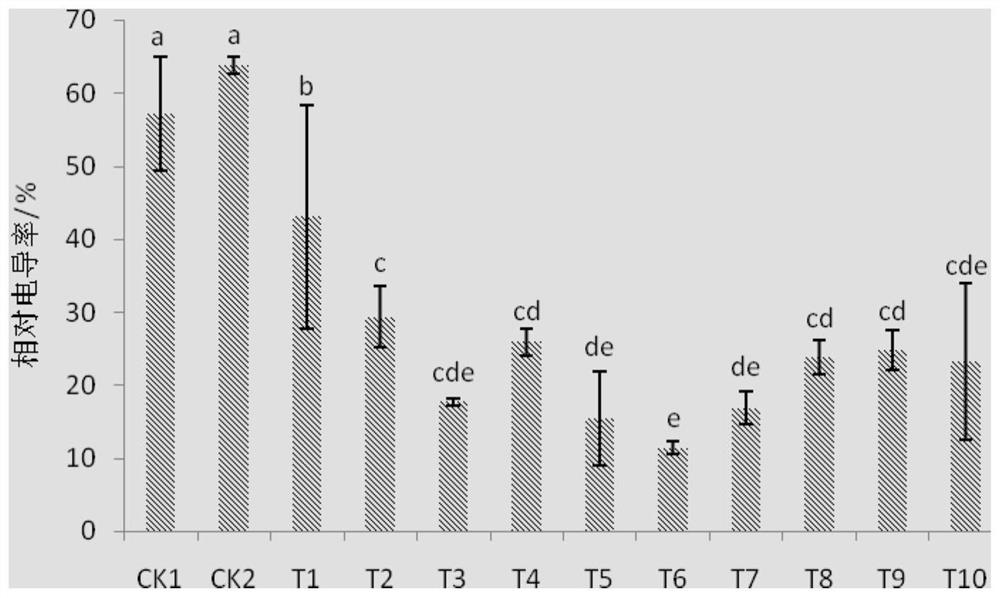

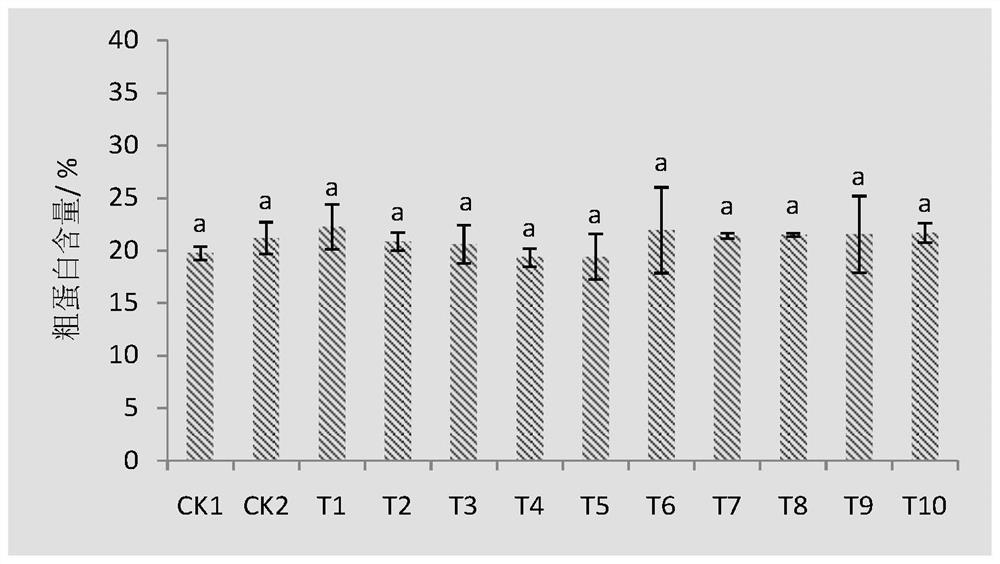

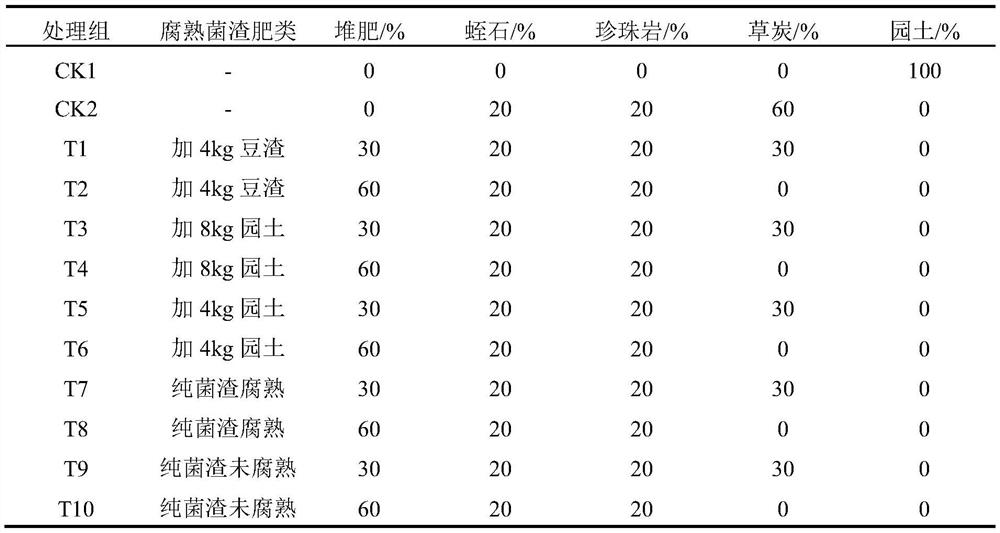

[0037] 1.1 In order to explore the optimal formulation of the cultivation substrate for ryegrass, multiple groups of cultivation substrates with different formulations were set up, and the corresponding cultivation substrate for ryegrass was prepared using the preparation method in Example 1. Wherein, the cultivation matrix formula is shown in Table 1, the decomposed bacteria residue fertilizer formula is shown in Table 2, the physical properties of each group of matrix formulas are shown in Table 3, and the chemical properties of each group of matrix formulas are shown in Table 4:

[0038] The volume percentage of the cultivation matrix formula of different treatments in table 1

[0039]

[0040] Table 2 Decomposed bacteria slag fertilizer formula

[0041]

[0042] The physical property of each group matrix formula of table 3

[0043]

[0044] The chemical properties of each group of matrix formulations in table 4

[0045]

[0046] It can be seen from Table 3 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com