Curing process of ten key temperature-stabilizing points for a honey-sweet flavor tobacco leaf

A baking process and key point technology, which is applied in the ten key point tobacco baking process fields of Honey Sweet Fragrance "442", can solve the problems of insufficient material conversion, stiffness of tobacco leaves, insufficient aroma, etc., to enhance chroma, avoid Stiffness, softness-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The verification test was carried out in Fenggang County, Guizhou Province in 2017, and the tested flue-cured tobacco variety: Yunyan 87. The tested tobacco leaves were cultivated and managed according to the standardized production of local high-quality tobacco leaves, and harvested according to the maturity standard. The test barn is a standard dense barn.

[0052] 1.1 Experimental design

[0053] Taking the main local baking process as the control, and using the "Ten Key Stable Temperature Points of Honey Sweet Fragrance 442" as the treatment, a comparative experiment was carried out.

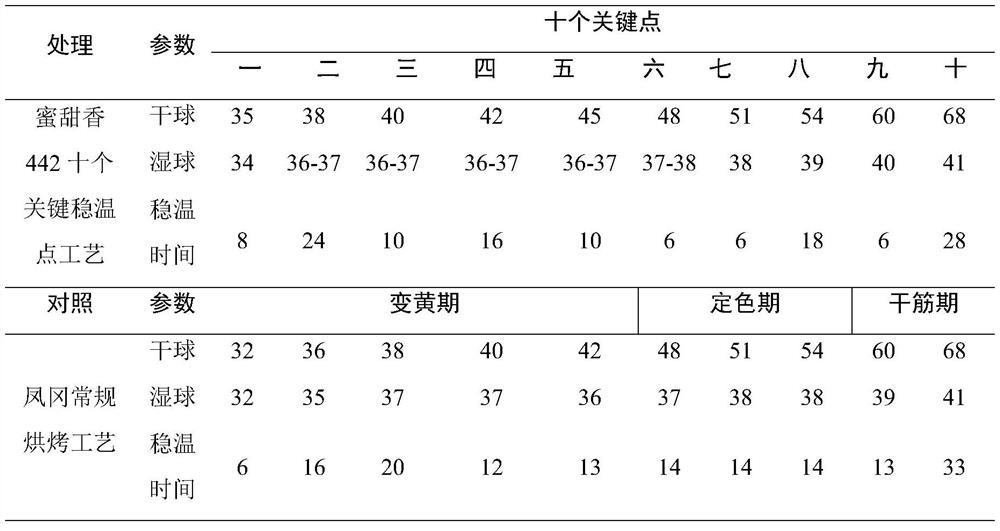

[0054] Table 1 Experimental Design Unit ℃, h

[0055]

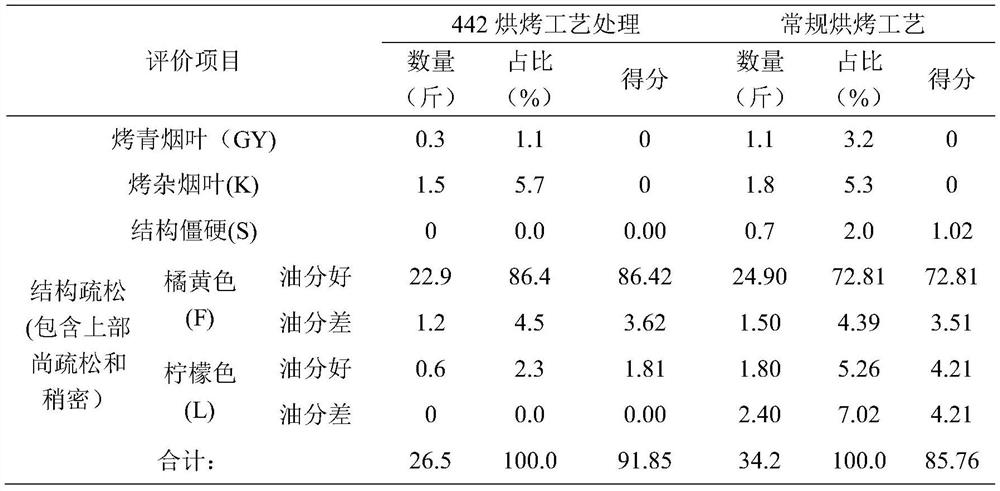

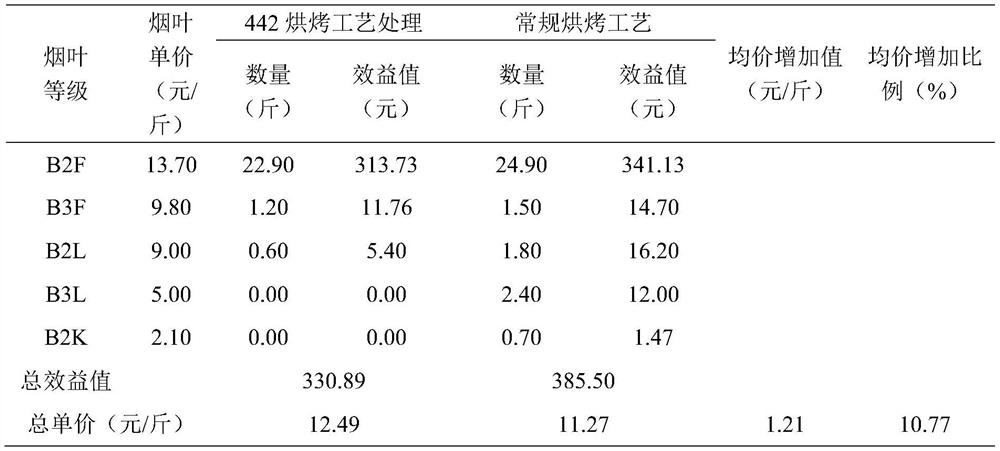

[0056] 1.2 Evaluation method of cured tobacco leaves

[0057] Randomly select the rehydrated tobacco leaves from the lower kang, untie the stems, mix them evenly, and classify them according to the evaluation criteria. After classification, calculate the proportion of each type of tobacco leaves according to the weight of e...

Embodiment 2

[0083] The verification test was carried out in Qianxi County, Guizhou Province in 2017, and the tested flue-cured tobacco variety: Yunyan 87. The tested tobacco leaves were cultivated and managed according to the standardized production of local high-quality tobacco leaves, and harvested according to the maturity standard. The test barn is a standard dense barn.

[0084] 2.1 Experimental design

[0085] Taking the main local baking process as the control, and using the "Ten Key Stable Temperature Points of Honey Sweet Fragrance 442" as the treatment, a comparative experiment was carried out.

[0086] Table 6. Experimental Design Unit ℃, h

[0087]

[0088] 2.2 Evaluation method of cured tobacco leaves

[0089] Randomly select the rehydrated tobacco leaves from the lower kang, untie the stems, mix them evenly, and classify them according to the evaluation criteria. After classification, calculate the proportion of each type of tobacco leaves according to the weight of ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com