Magnetostriction ultrasonic cleaning valve

A technology of ultrasonic cleaning and magnetostriction, applied in the field of cleaning valves, can solve the problems of difficult high-speed water flow output, poor maneuverability, weak and popular application, etc., and meet the needs of engineering applications, high magnetic-machine coupling characteristics, easy to install and disassemble Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

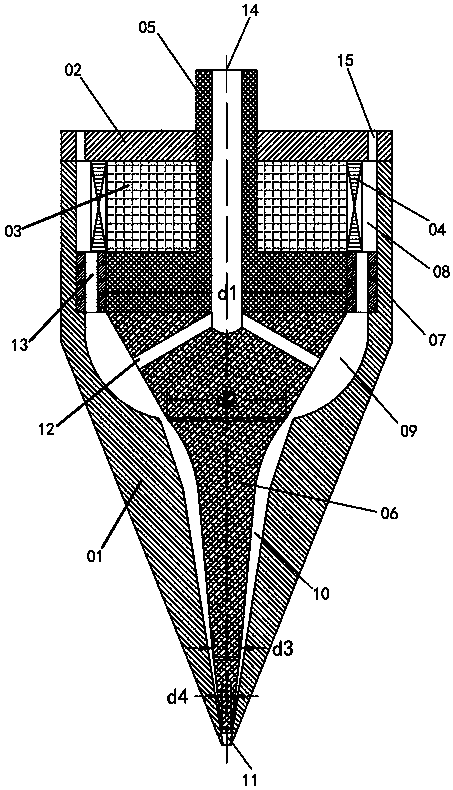

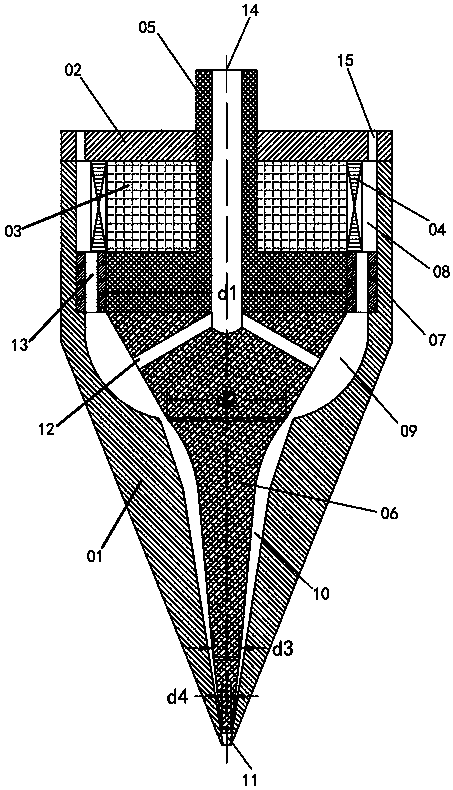

[0018] A magnetostrictive ultrasonic cleaning valve, comprising a valve body 01, an end cover 02, a giant magnetostrictive material 03, a mass block 05, an abrasive material inlet 14, and a water inlet 15. The giant magnetostrictive material 03 adopts a ring structure and is sleeved on On the boss of the T-shaped mass 05, the outer surface of the giant magnetostrictive material 03 is bonded with an excitation coil 04. The T-mass 05 adopts a hollow structure, and its right end is welded with a horn 06, and the left bottom of the horn 06 is provided with a V-shaped through groove, and the through groove and the through groove of the T-mass 05 form an abrasive channel 12 .

[0019] The end face of the T-shaped mass block 05 is bonded with a flange 07, and the flange 07 is provided with water flow grooves 13 up and down. The giant magnetostrictive material 03, the exciting coil 04, the mass block 05, the horn 06 and the flange 07 are placed in the center of the valve body 01 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com