High-strength high-ductility high-modulus aluminum alloy material based on extrusion casting technique, and preparation process of high-strength high-ductility high-modulus aluminum alloy material

An aluminum alloy material and extrusion casting technology, which is applied in the field of metal materials, can solve the problems that the elastic modulus and strength of aluminum alloy cannot meet the use requirements, achieve excellent mechanical properties, improve the elastic modulus of the alloy, and have the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

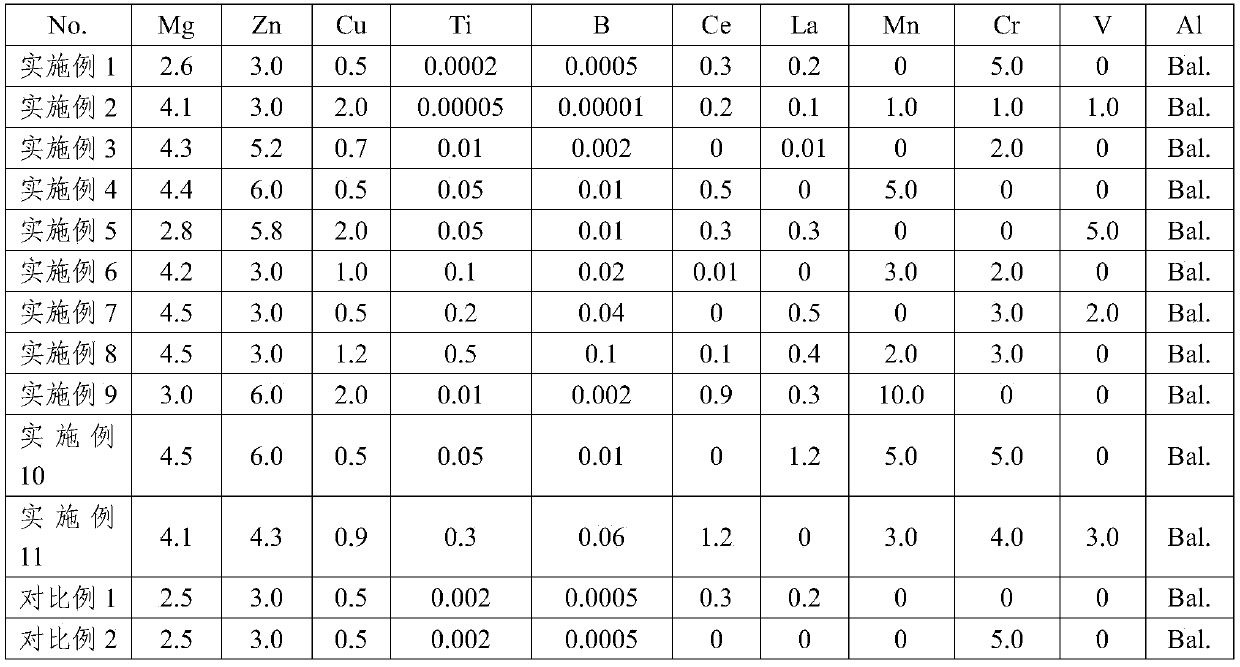

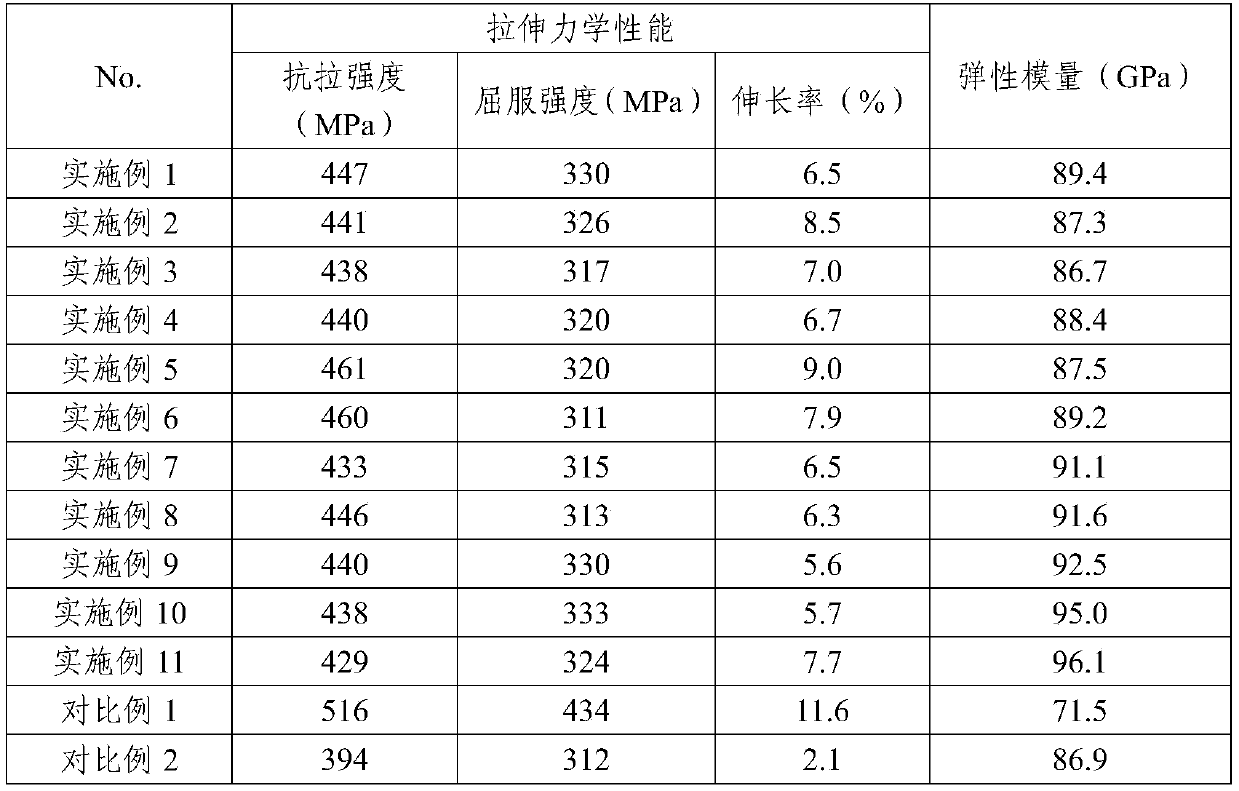

[0035] The high-strength and high-modulus aluminum alloy material provided in this embodiment is composed of the following elements in terms of mass percentage: Mg: 2.6%, Zn: 3.0%, Cu: 0.5%, Ti: 0.002%, B: 0.0005%, Ce: 0.3%, La: 0.2%, Cr: 5.0%, and unavoidable impurities Fe≤0.3%, Si≤0.15%, Al balance. Its extrusion casting method steps are as follows:

[0036]a. Melting the alloy to obtain an aluminum alloy melt. Melting steps: (1) Baking, preheating the raw materials at 250°C for 2 hours; (2) Melting, setting the melting temperature of the melting furnace to 800°C, and when the furnace temperature rises to 300°C, add industrial pure aluminum, aluminum-copper master alloy , to melt, stir evenly; melt temperature rises to 760°C, add industrial pure zinc, aluminum-cerium, aluminum-lanthanum, aluminum-chromium intermediate alloy, stir evenly, until melt clear; when the melt temperature drops to 720°C , add industrial pure magnesium, melt, and stir evenly until the melt is clear...

Embodiment 2

[0041] The high-strength, toughness and high-modulus aluminum alloy material provided in this embodiment is composed of the following elements in terms of mass percentage: Mg: 4.1%, Zn: 3.0%, Cu: 2.0%, Ti: 0.00005%, B: 0.00001%, Ce: 0.2%, La: 0.1%, Mn: 1.0%, Cr: 1.0%, V: 1.0%, and unavoidable impurities Fe≤0.3%, Si≤0.15%, Al balance. Its extrusion casting method steps are as follows:

[0042] a. Melting the alloy to obtain an aluminum alloy melt. Melting steps: (1) Baking, preheating the raw materials at 250°C for 2 hours; (2) Melting, setting the melting temperature of the melting furnace to 800°C, and when the furnace temperature rises to 300°C, add industrial pure aluminum, aluminum-copper master alloy , until melted, and stirred evenly; the melt was heated up to 760°C, and industrial pure zinc, aluminum-cerium, aluminum-lanthanum, aluminum-manganese, aluminum-chromium, aluminum-vanadium intermediate alloys were added, stirred evenly, until melted; When the melt temperatu...

Embodiment 3

[0047] The high-strength, toughness and high-modulus aluminum alloy material provided in this embodiment is composed of the following elements in terms of mass percentage: Mg: 4.3%, Zn: 5.2%, Cu: 0.7%, Ti: 0.01%, B: 0.002%, La: 0.01 %, Cr: 0.1%, and unavoidable impurities Fe≤0.3%, Si≤0.15%, Al balance. Its extrusion casting method steps are as follows:

[0048] a. Melting the alloy to obtain an aluminum alloy melt. Melting steps: (1) Baking, preheating the raw materials at 250°C for 2 hours; (2) Melting, setting the melting temperature of the melting furnace to 800°C, and when the furnace temperature rises to 300°C, add industrial pure aluminum, aluminum-copper master alloy , until the melt is clear, and stir evenly; the melt is heated to 760°C, add industrial pure zinc, aluminum-lanthanum, aluminum-chromium intermediate alloy and stir evenly until the melt is clear; when the melt temperature drops to 720°C, add industrial pure magnesium , melted, and stirred evenly until th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap