Intelligent spreader for prefabricated concrete part, and intelligent spreading method

A distributing machine and distributing technology, applied in the direction of manufacturing tools, ceramic molding machines, supply devices, etc., can solve the problems of unguaranteed product quality of concrete prefabricated parts, high requirements for workers' operation skills, and limited fluidity of concrete, etc., and achieve reduction Artificial influence factors and labor cost, guarantee product quality, high uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

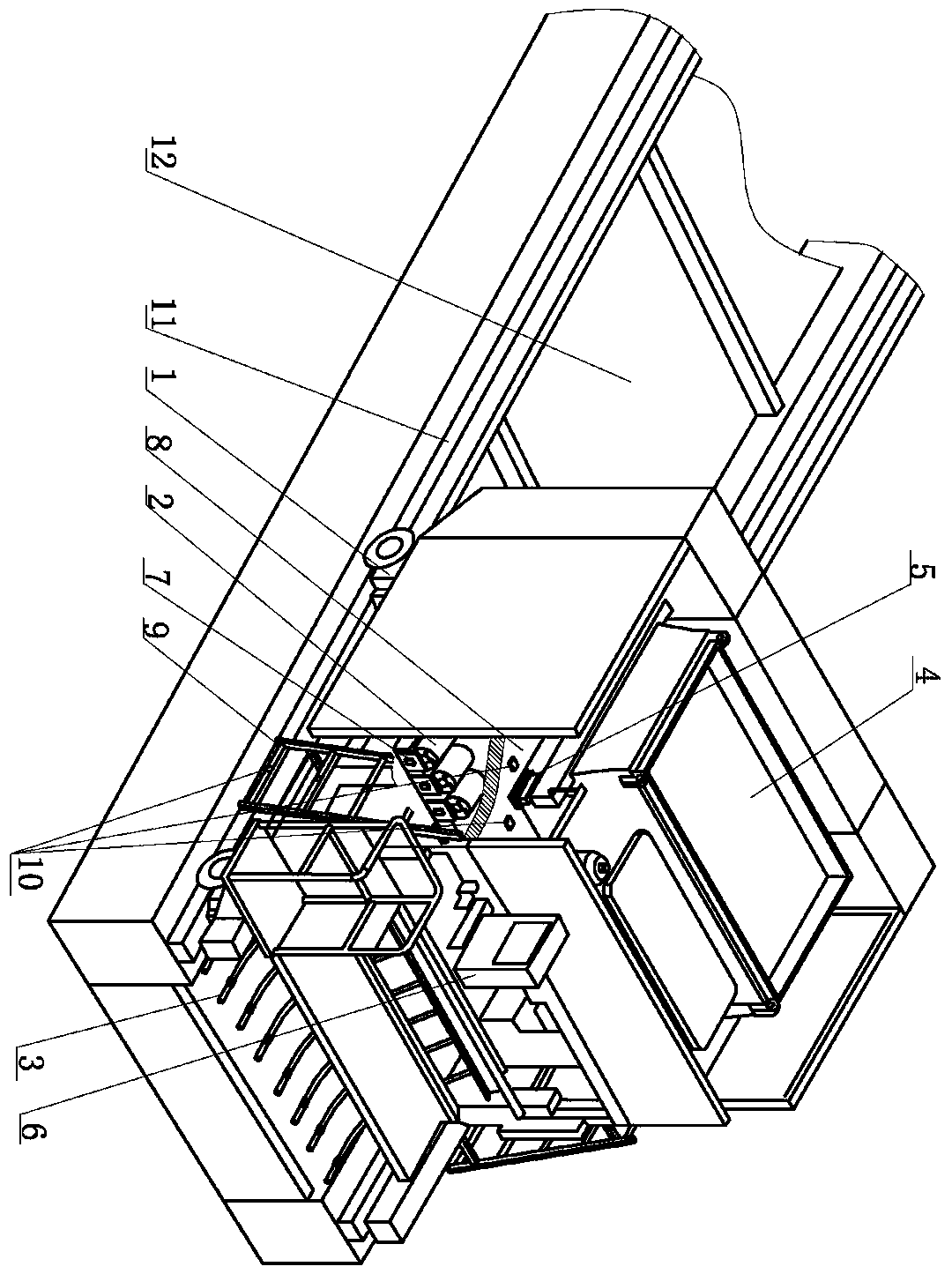

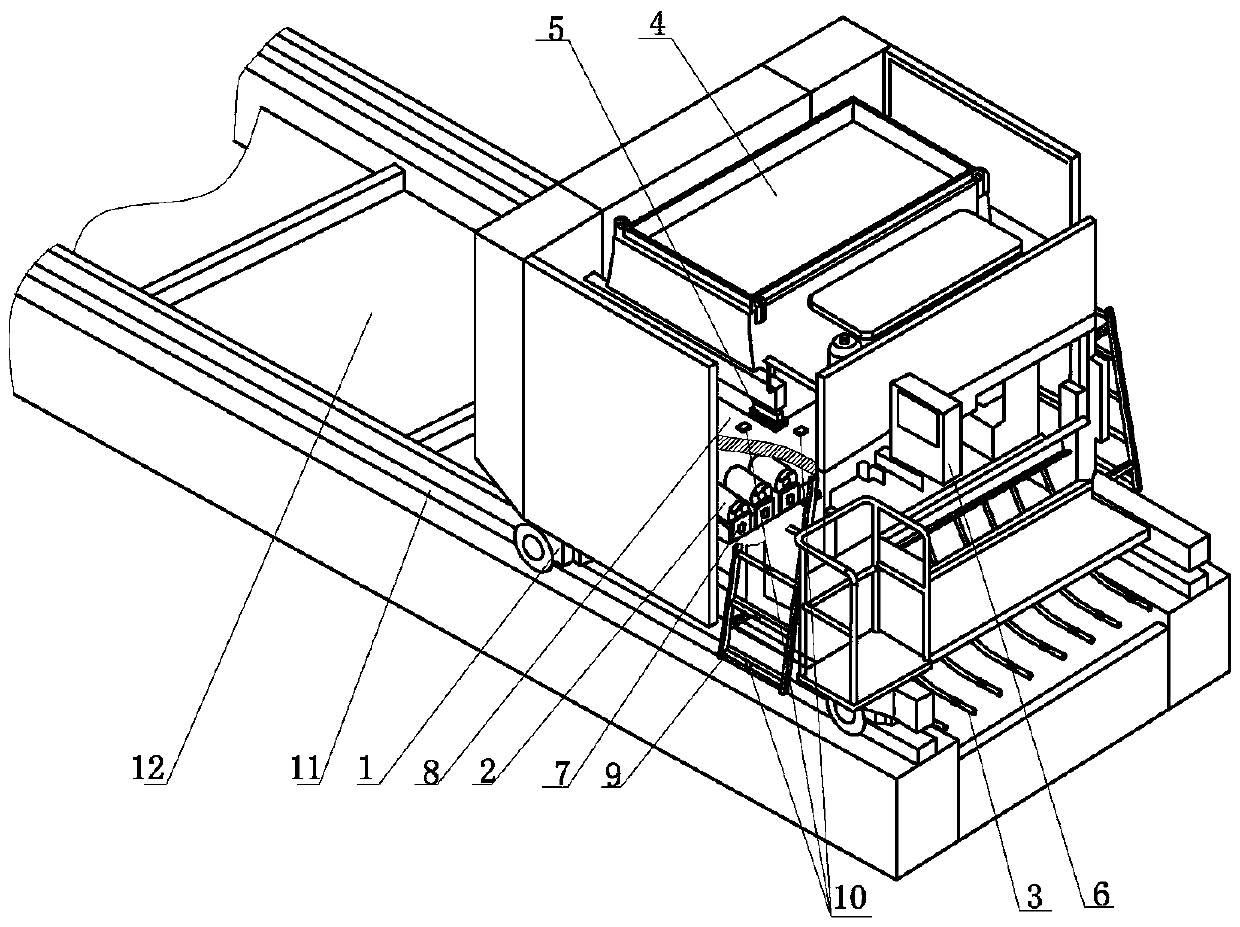

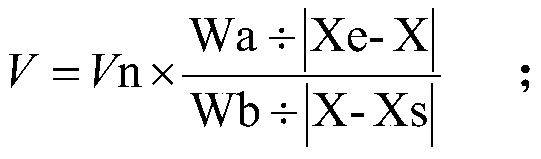

[0022] An intelligent distributing machine for prefabricated concrete parts according to the present invention includes a traveling mechanism 1, which can walk along its track 11 under the drive of a traveling motor. condensate mold 12, such as figure 1 As shown, a hopper 4 and a vibrating mechanism 3 are installed on the walking mechanism 1, the hopper 4 is used to hold the concrete to be distributed, the vibrating mechanism 3 is used to mix and compact the concrete falling into the mold, and a screw is installed under the hopper 4. The distributing mechanism 2 and the vibrating mechanism 3 are located behind the traveling direction of the screw distributing mechanism 2 when distributing. The traveling mechanism 1 and the hopper 4 are connected by a weighing element 5, which can measure the total weight of the hopper 4 and the screw distributing mechanism 2 in real time. Weight, the electric control valve 7 is installed at the discharge port of the screw material distribution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com