Device and method for detecting mixing effect of eccentric rotor extruder on line

An eccentric rotor and extruder technology, which is applied in the field of online detection, can solve the problems of low detection accuracy, the inability of measuring devices to apply to eccentric rotor extruders, and the lack of evaluation devices for the processing effect of eccentric rotor extruders, etc., to achieve accuracy Improve the effect of good generalization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

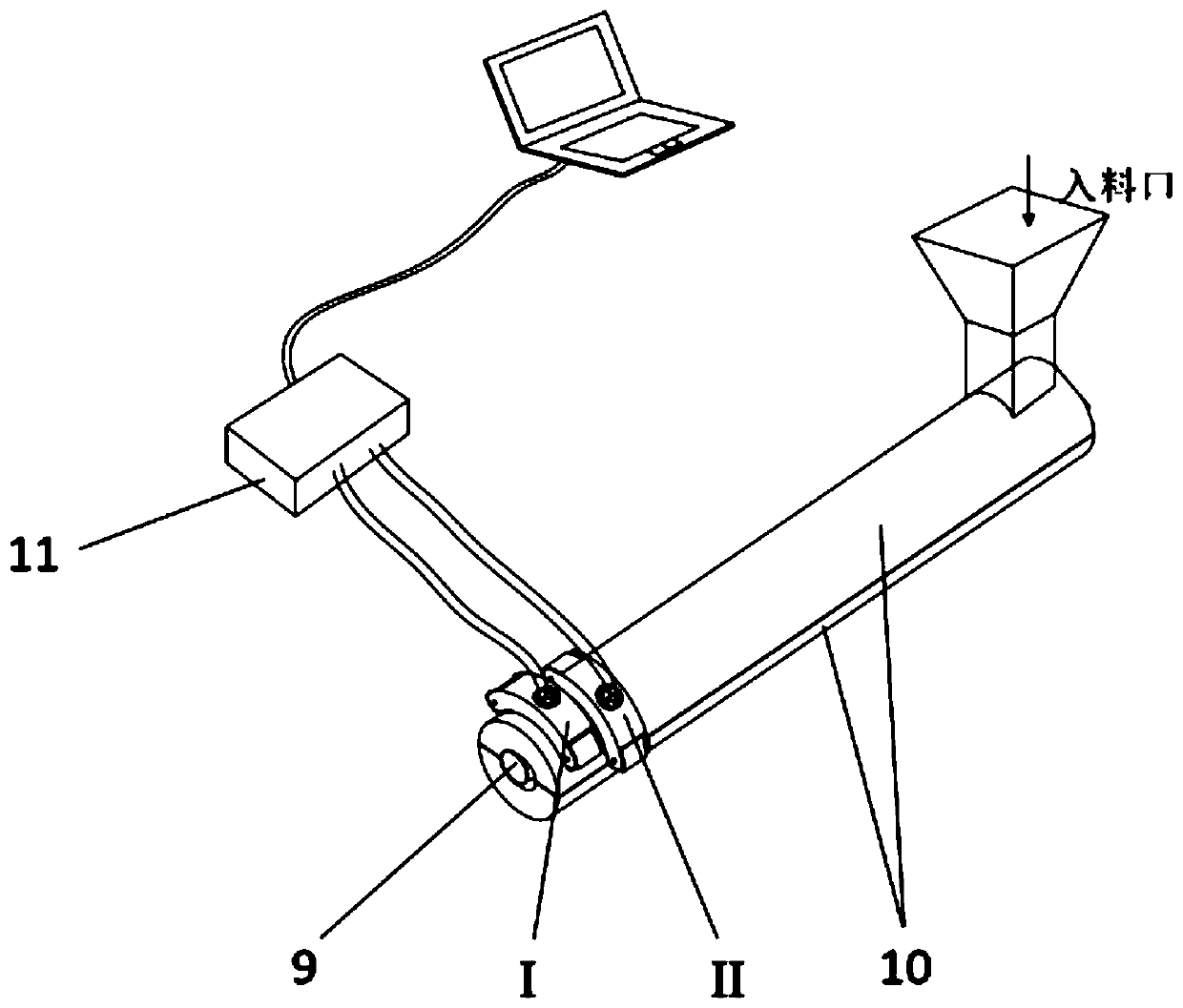

[0033] Such as figure 1 and figure 2 As shown, a device for online detection of the blending effect of an eccentric rotor extruder includes a computer, an ultrasonic detector 11, an air-coupled ultrasonic transmitter I and an air-coupled ultrasonic receiver II, an eccentric rotor 9, and a stator 10 , the computer is connected to the ultrasonic detector 11, and the ultrasonic detector 11 is respectively connected to the air-coupled ultrasonic transmitting device I and the air-coupled ultrasonic receiving device II, and the three constitute an ultrasonic signal processing system, and the air-coupled ultrasonic The ultrasonic transmitting device I and the air-coupled ultrasonic receiving device II are arranged on the stator 10 of the eccentric rotor extruder;

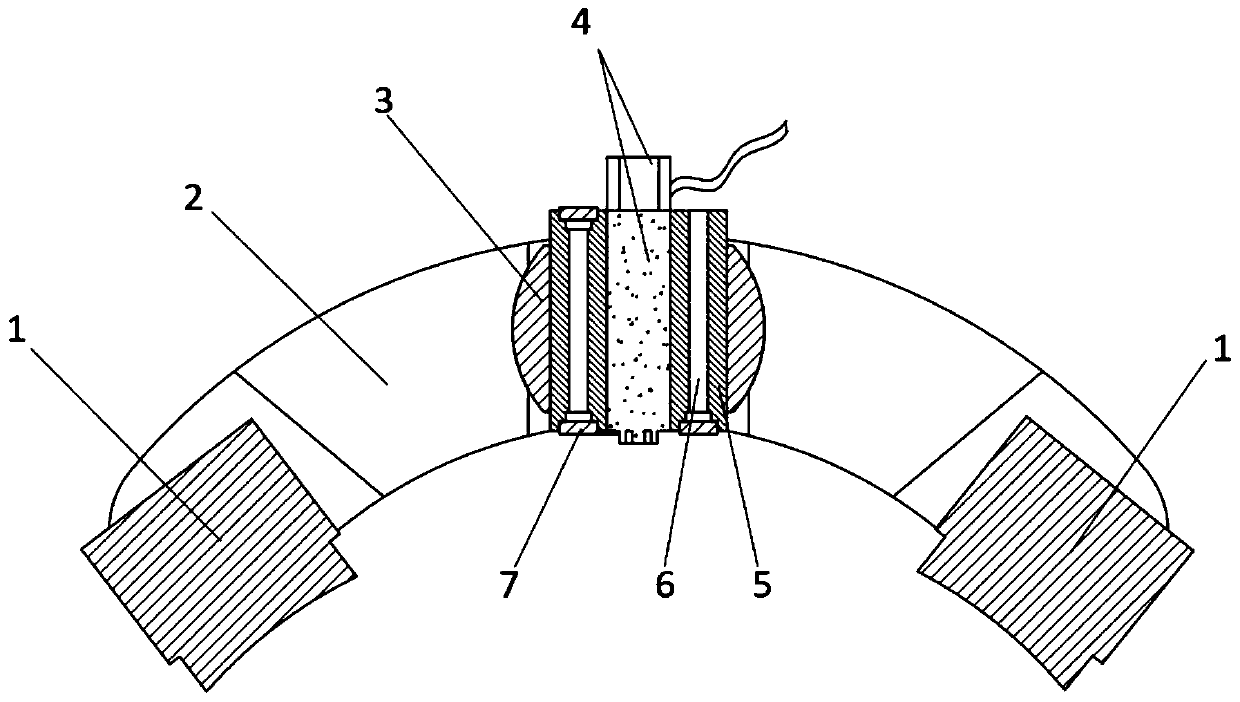

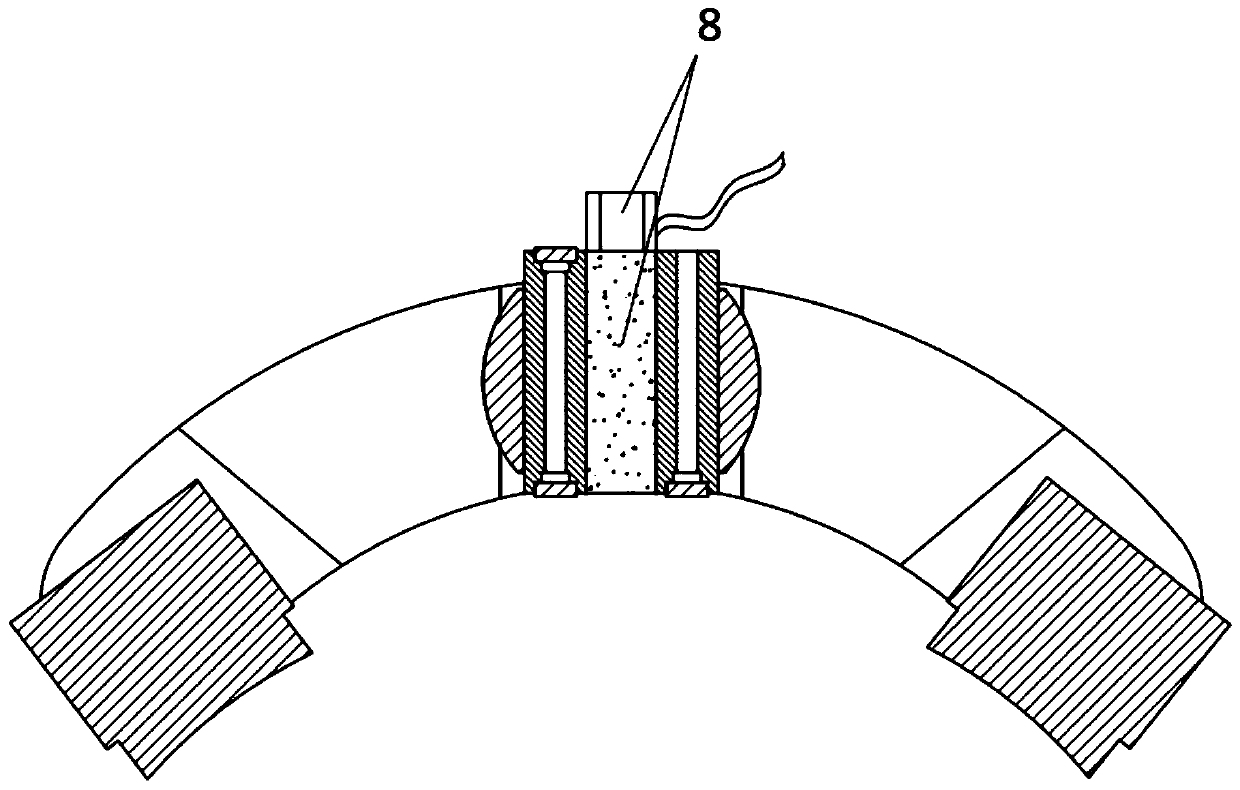

[0034] The air-coupled ultrasonic transmitting device such as figure 2 As shown, it consists of two high temperature resistant magnets 1, a cage 2, a spherical joint 3, an ultrasonic transducer transmitting probe 4 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com