Ozone generator

A technology of ozone generator and internal electrode, which is applied in the direction of ozone preparation, ozone preparation by discharge method, oxygen/ozone/oxide/hydroxide, etc., which can solve the problem of glue breaking at the joint of tube cap, low electrolysis efficiency, and cost increase, etc. problems, to achieve the effect of convenient processing and assembly, good electrolysis efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

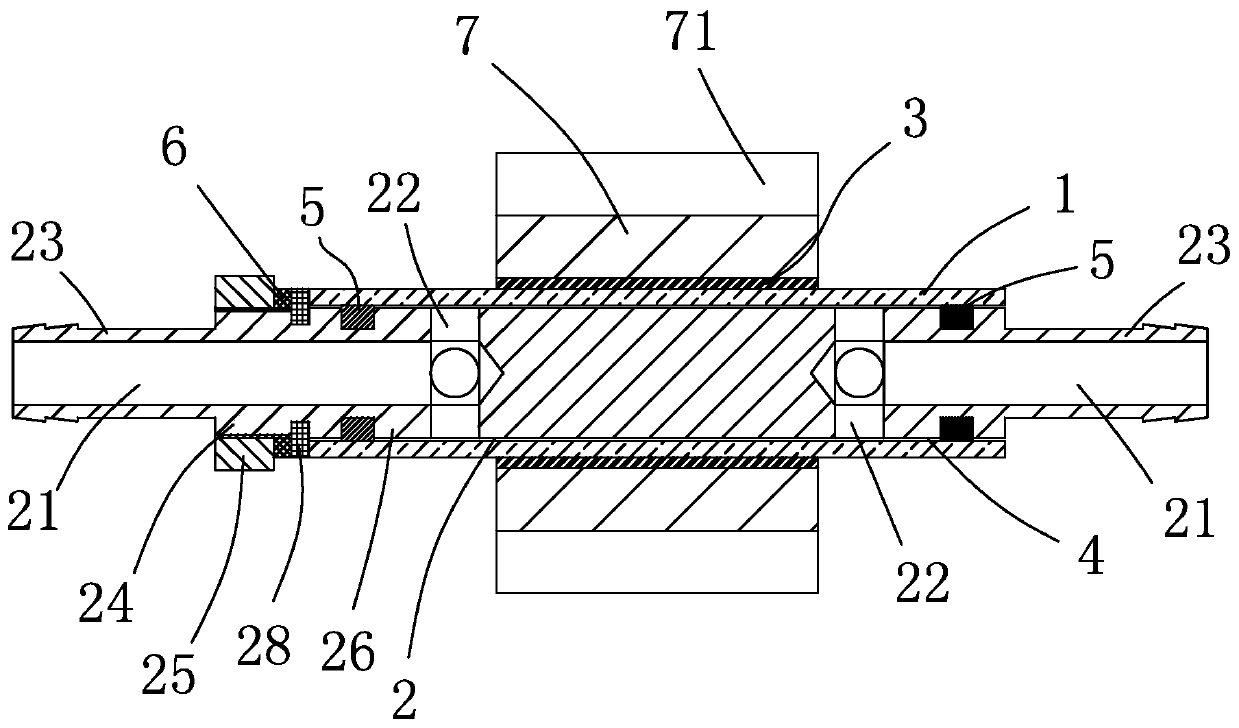

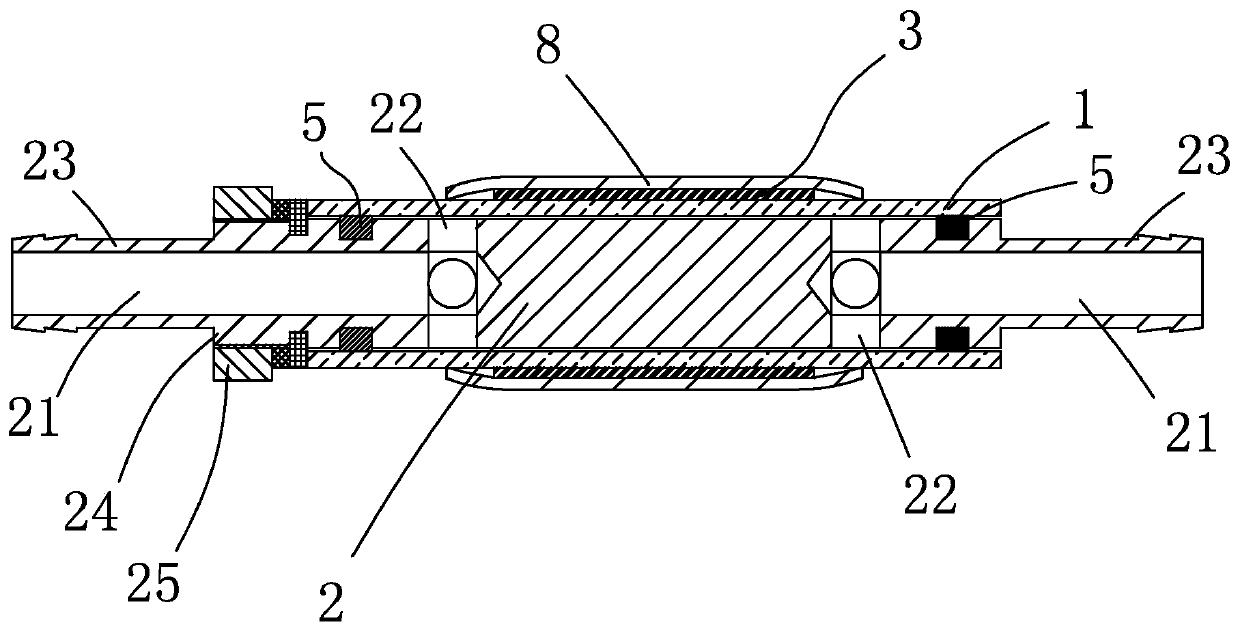

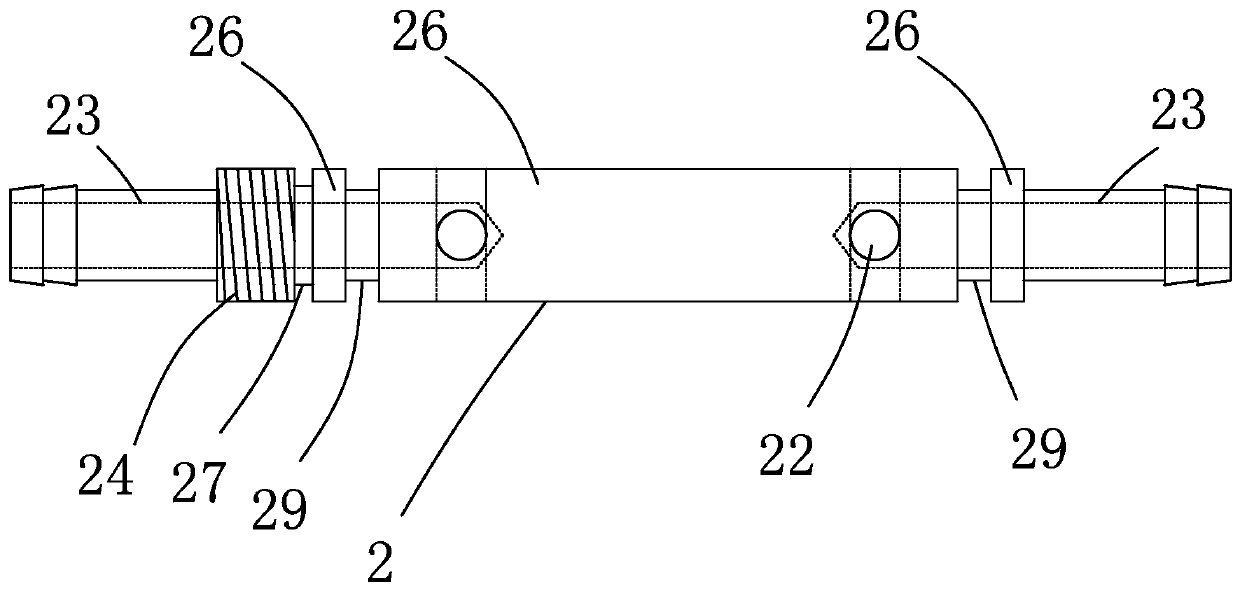

[0035] The embodiment of ozone generator of the present invention is such as Figure 1-5 As shown: it includes a dielectric tube 1, an inner electrode 2, and an outer electrode 3. The dielectric tube 1 can be made of glass, quartz or ceramic material, and is preferably made of glass in the embodiment of the present invention. The inner electrode 2. The outer electrodes 3 are coaxially sleeved on the inner and outer sides of the dielectric tube 1 respectively. The inner electrode 2 and the dielectric tube 1 are spaced apart and formed with an electrolysis channel 4. The two ends of the inner electrode 2 are (including positions close to both ends) is sleeved with a sealing ring 5, and the sealing ring 5 is tightly arranged between the outer side of the inner electrode 2 and the inner side of the dielectric tube 1, and the two ends of the electrolysis channel are limited by the sealing ring 5 , both ends of the inner electrode 2 are provided with flow guide channels 21, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com