Multistage segmental malaxation cold adding recycled asphalt concrete plant mixing device and method

A technology of recycled asphalt and asphalt concrete, which is applied in roads, constructions, road repairs, etc., can solve the problems of high energy consumption, poor product quality, and high production costs, and achieve the effects of low energy consumption, low production costs, and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The implementation mode of the present invention is illustrated by specific specific examples below, and those who are familiar with this technology can easily understand other advantages and effects of the present invention from the contents disclosed in this description. Obviously, the described embodiments are a part of the present invention. , but not all examples. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

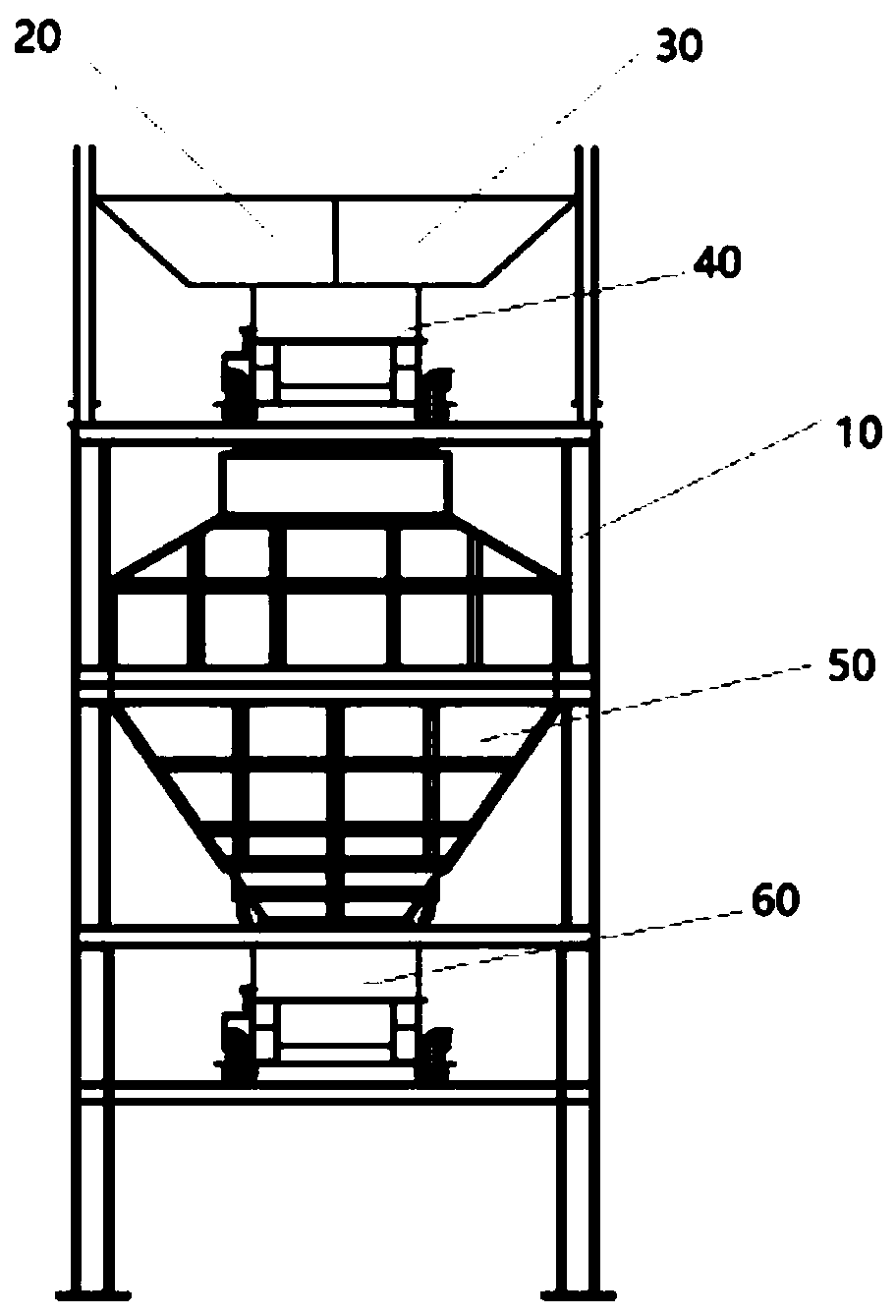

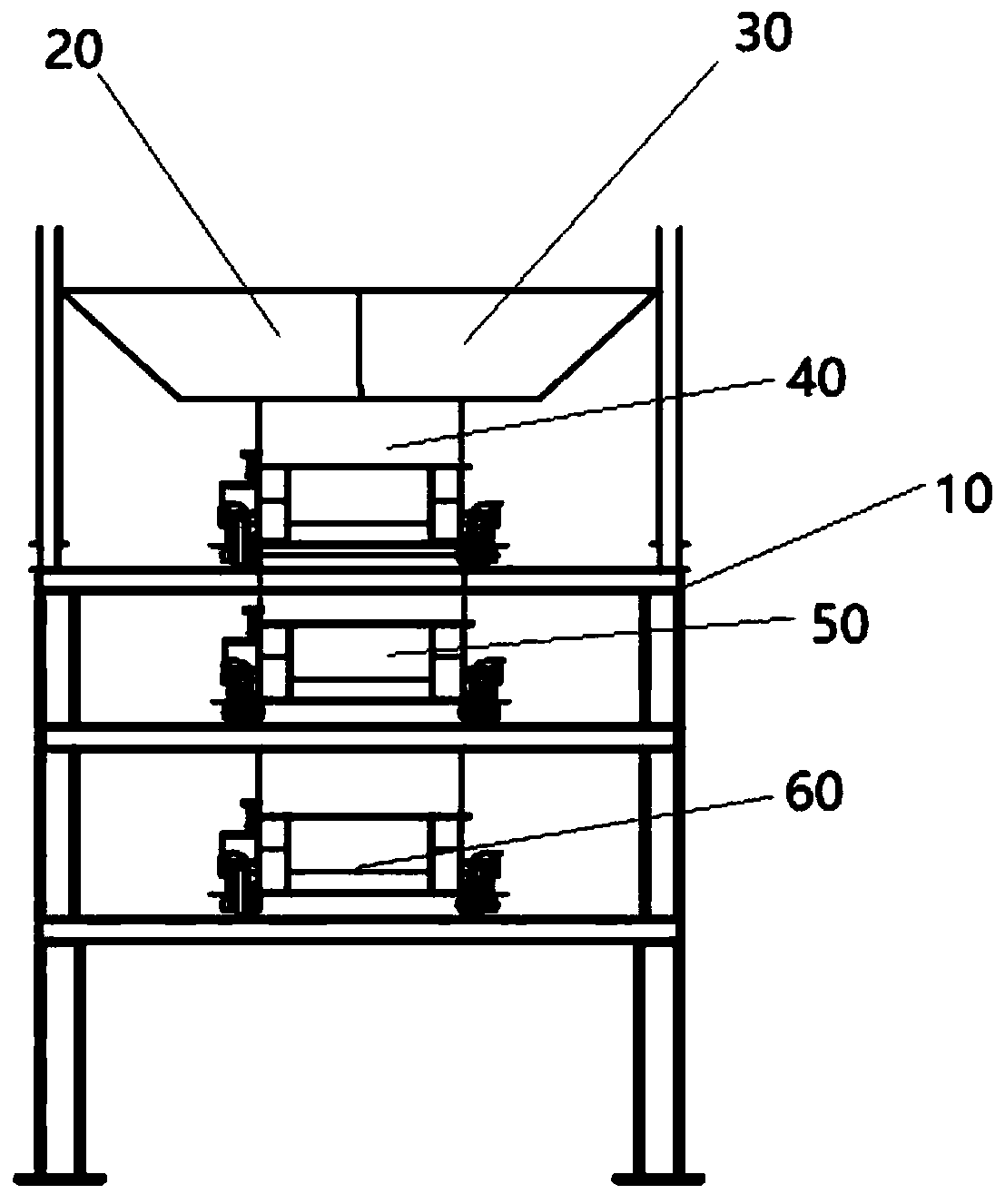

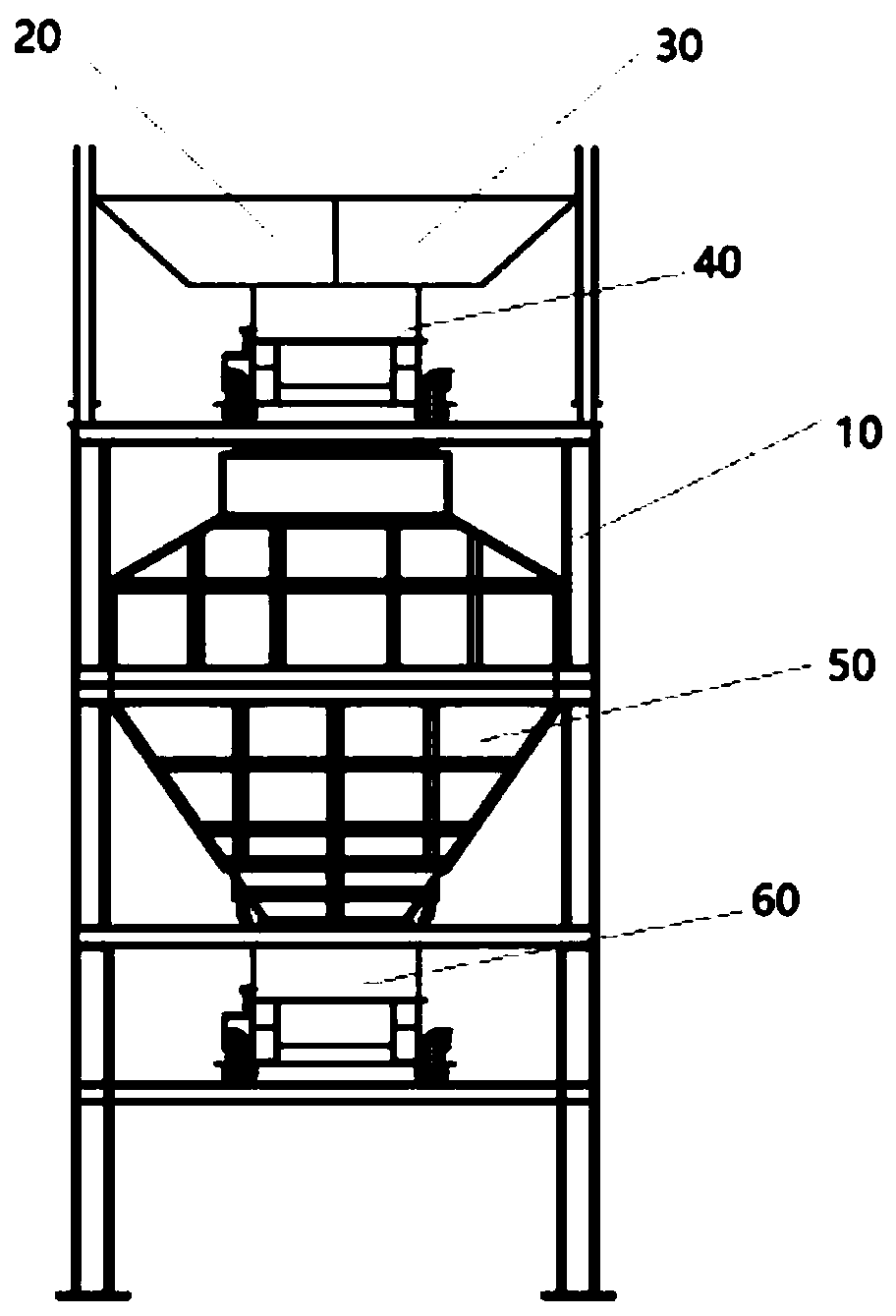

[0032] Such as figure 1 As shown, the multi-stage segmental mixing cold addition recycled asphalt concrete plant mixing equipment includes a frame body 10, a hot material scale 20, a cold addition material scale 30, a primary mixing tank 40, a hot material storage bin 50 and a secondary mixing The cylinder 60, wherein the frame body 10 is a cuboid frame body welded by a plurality of angle steels...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com