Shield tunnel end reinforcement method

A shield tunnel and end technology, which is applied in the field of shield tunnel end reinforcement, can solve problems such as complex environment at the entrance, increased safety risks, and failure of end reinforcement to meet the construction conditions of cement system reinforcement, etc., to achieve improved soil Improvement of body weight and soil strength, and effect of preventing water leakage at the door

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

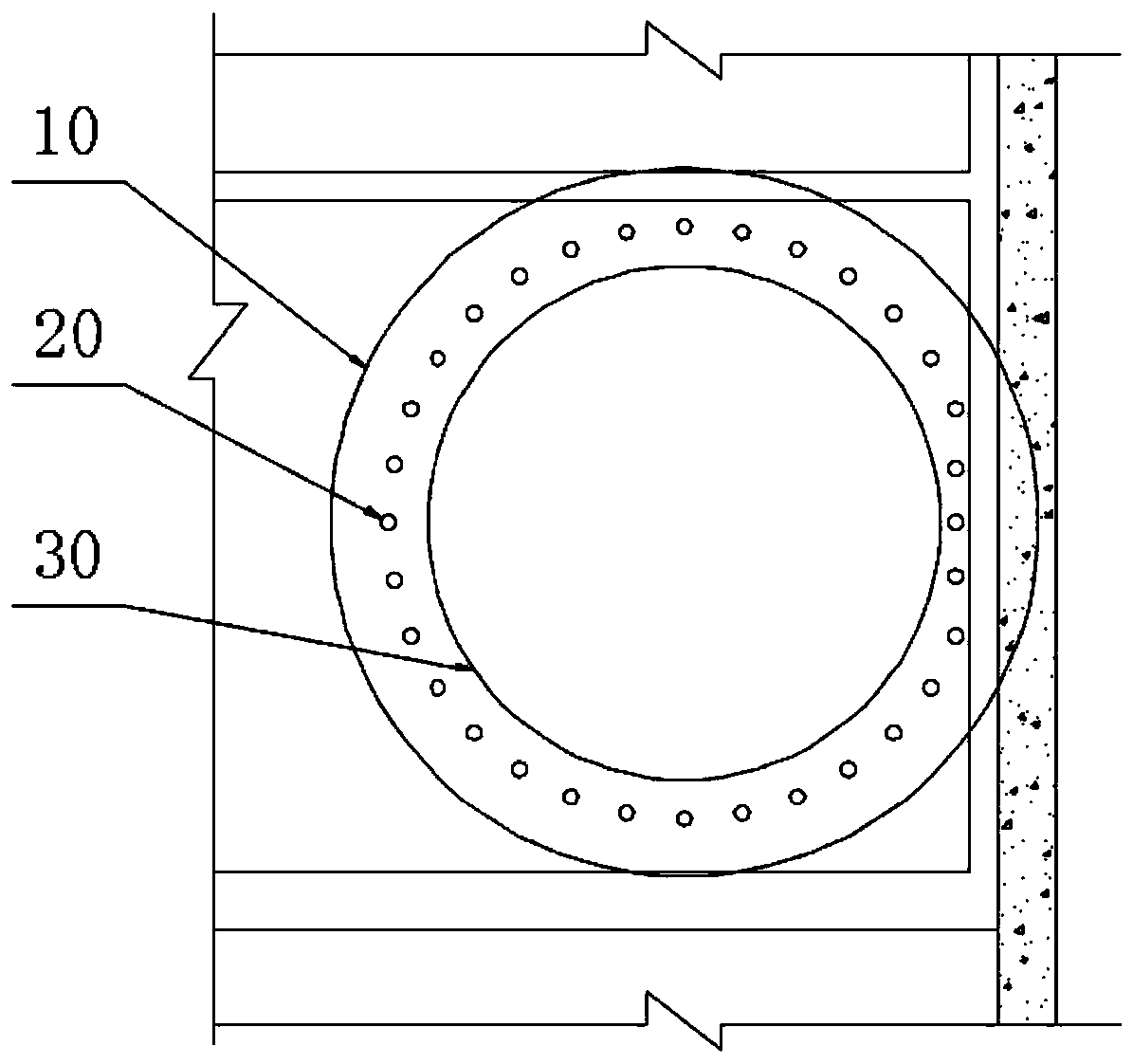

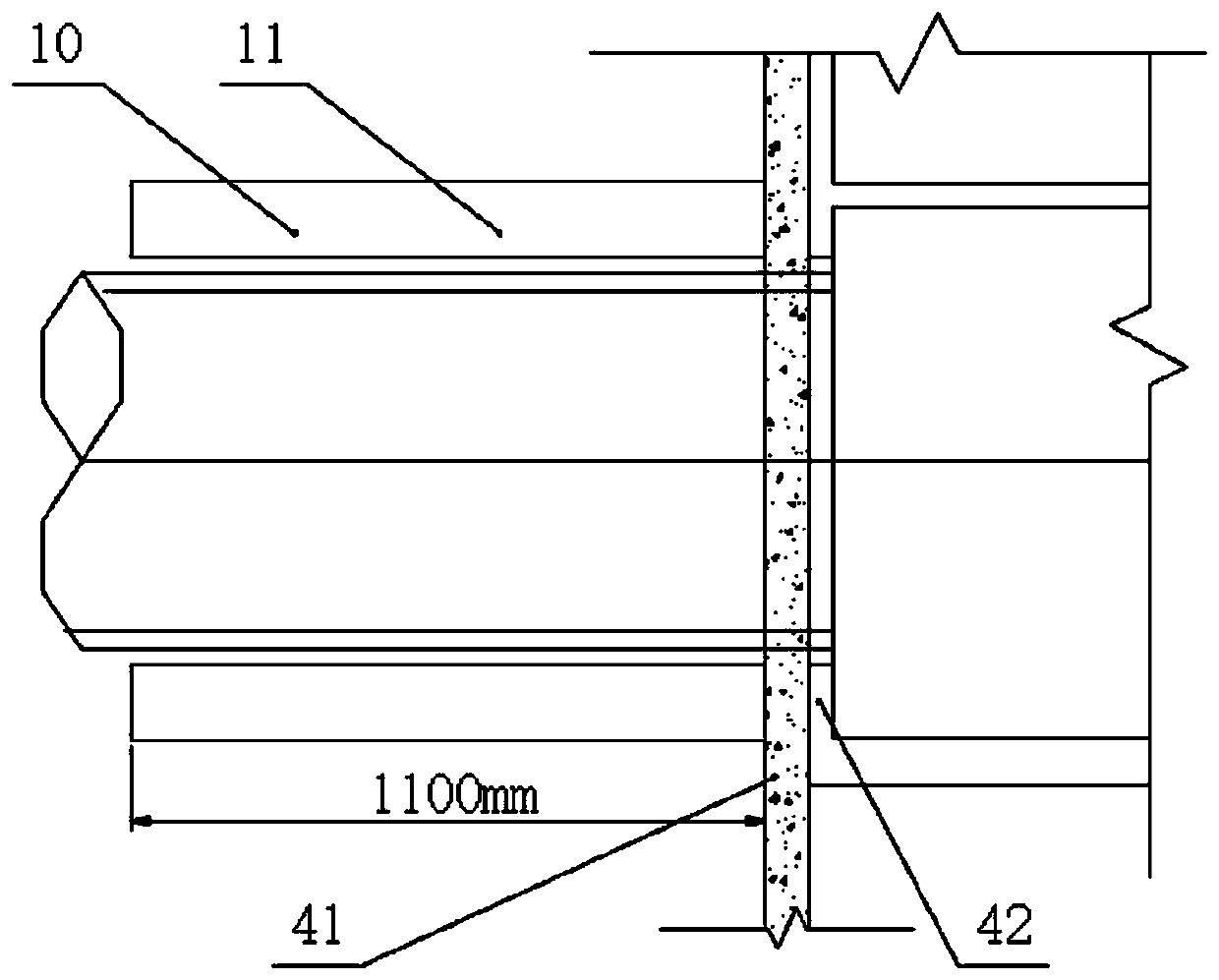

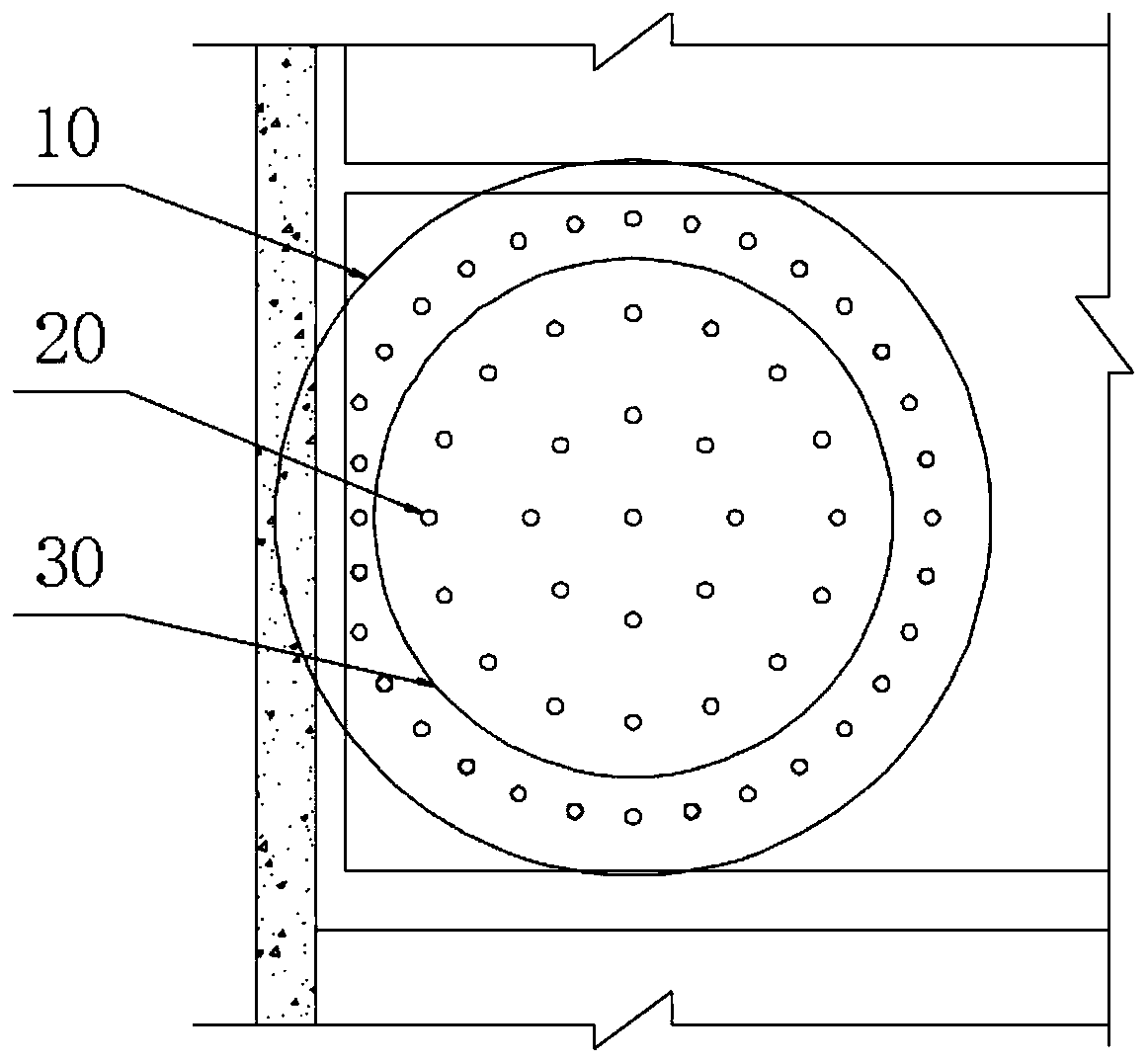

[0026] The specific implementation manner of the present invention will be described in more detail below with reference to schematic diagrams. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0027] An embodiment of the present invention provides a method for strengthening the end of a shield tunnel. When the ground environment at the entrance cannot be reinforced by a combination of three-axis stirring piles and high-pressure rotary grouting piles, three-axis stirring piles or high-pressure rotary grouting piles are used. Spray piles are used to reinforce the stratum at the portal to harden the soft soil to increase the stratum strength at the portal, and then arrange it along the circumference of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com