Foldable arch-frame type tunnel waterproof board installation vehicle

A technology for tunnel waterproof boards and installation vehicles, which is applied in tunnels, tunnel linings, shaft equipment, etc., which can solve the problems of difficult processing, inability to fold, and high production costs, so as to reduce construction auxiliary time, reduce occupied space, and facilitate The effect of handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

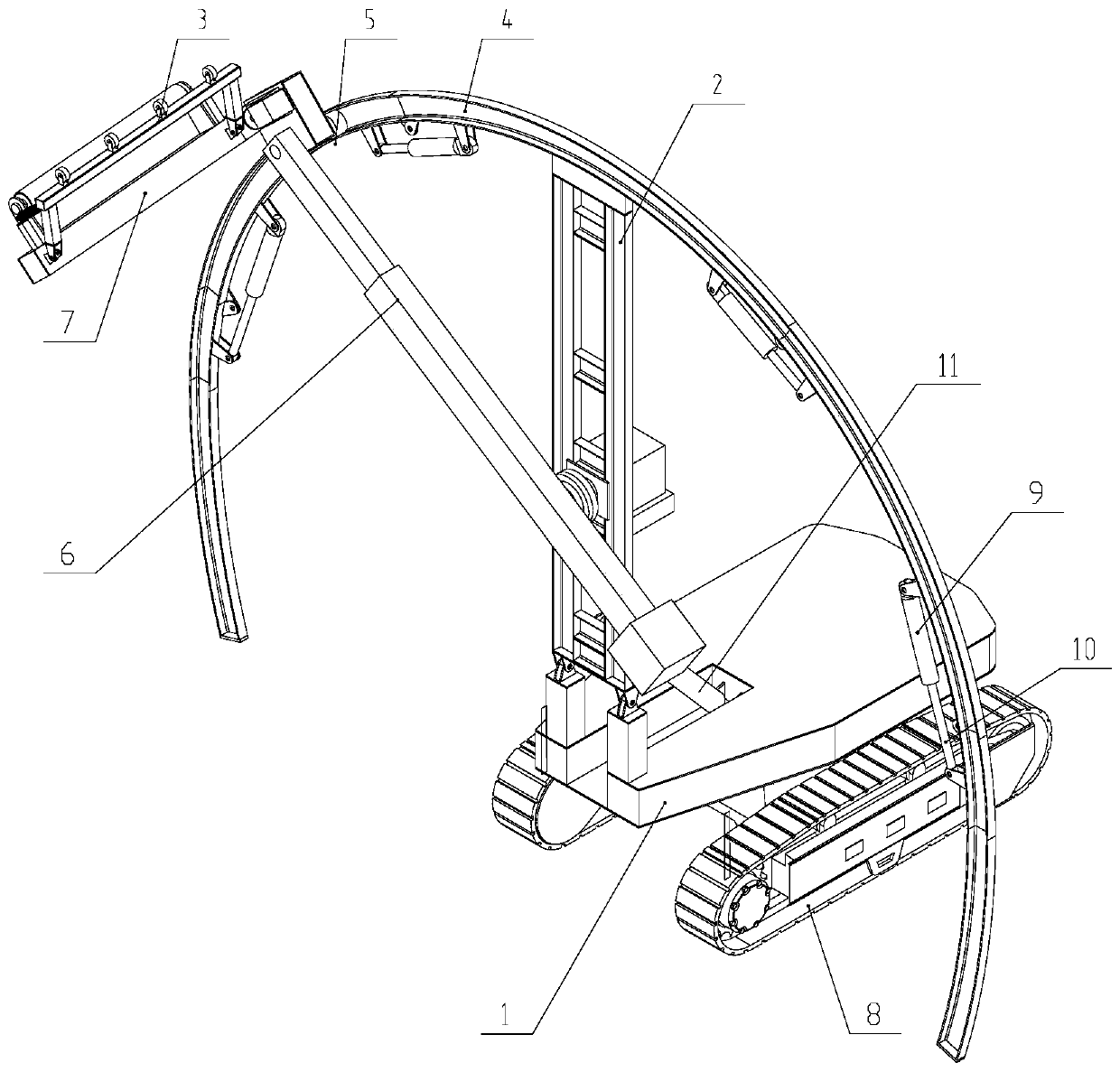

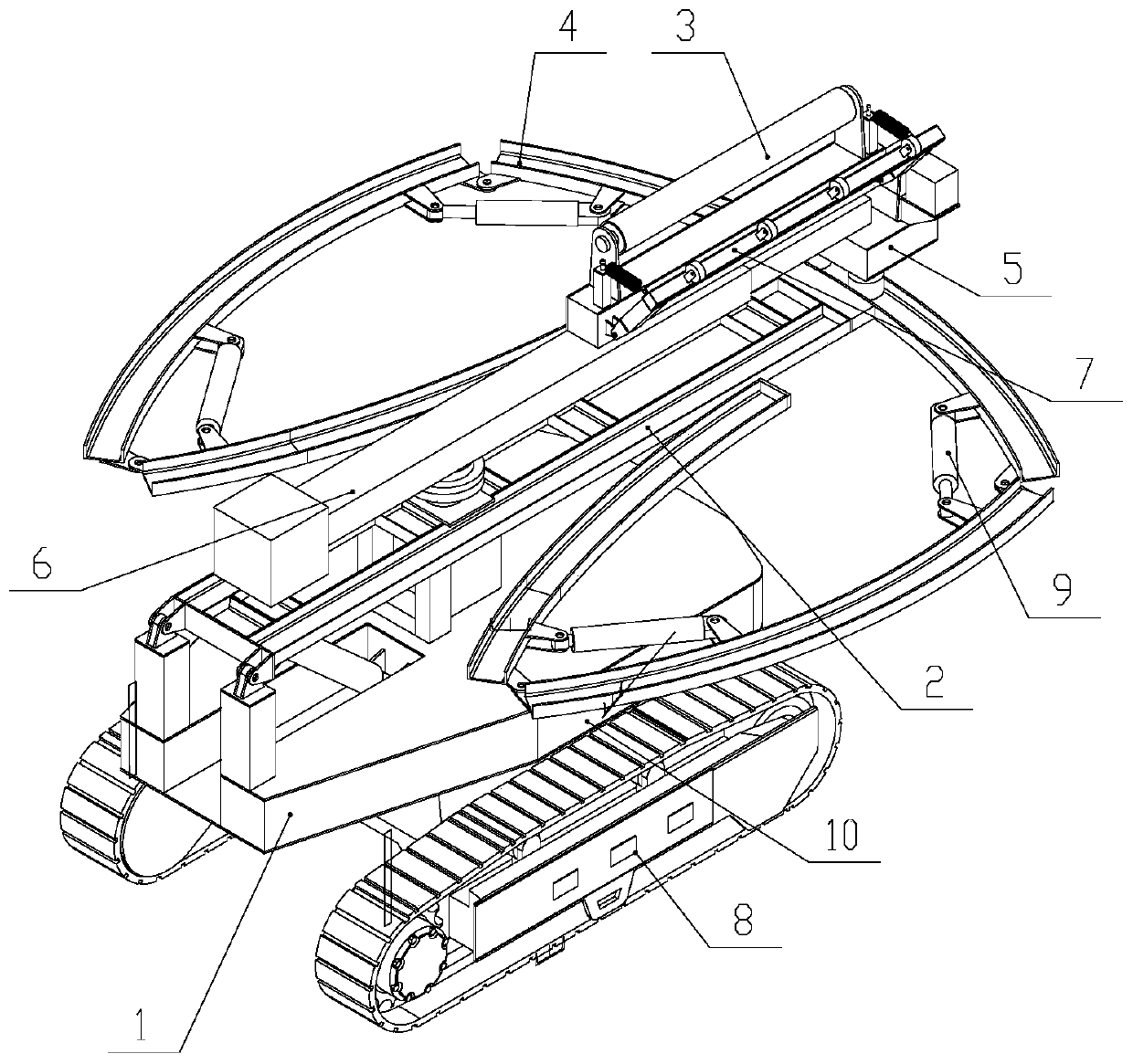

[0029] The following will combine Figure 1 to Figure 10 The present invention is described in detail, and the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

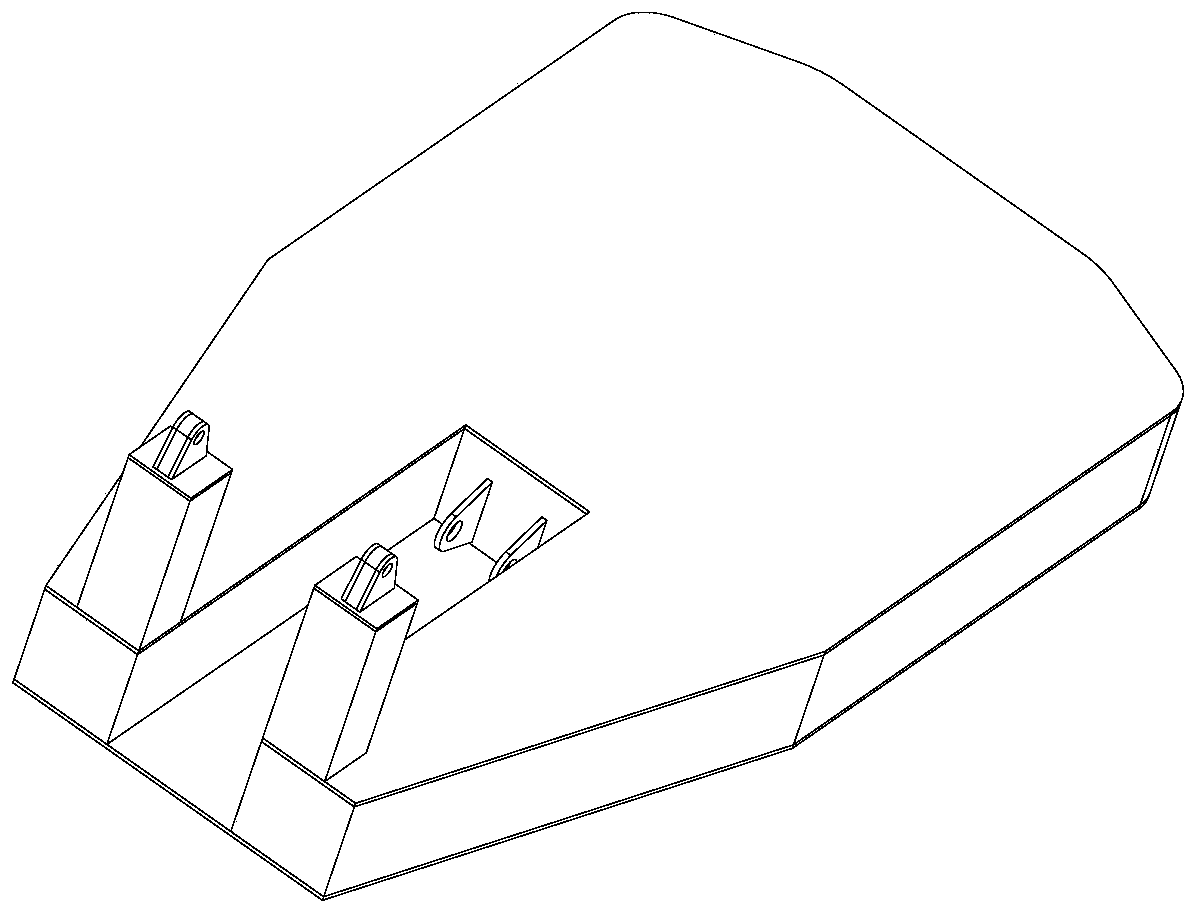

[0030] A foldable arch type tunnel milling machine, comprising a lower vehicle body, a support frame 2 arranged on the lower vehicle body and stretched / folded with the lower vehicle body, a display panel arm frame 7, and a display panel arm The exhibition panel pressing device 3 on the frame, the walking track 4 that can be extended / folded, the walking trolley 5 and the rotating arm frame 6; the exhibition panel arm frame and the exhibition panel pressing device are both extended / folded with the walking trolley The rotating arm frame on the support frame drives the display panel arm frame and the display panel pressing device to move along the traveling track through the walking trolley to realize the installation of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com