Bridge crossing part and preparing method thereof

A pipe fitting and the same technology, applied in the field of bridge parts and its preparation, can solve the problems of occupying a large volume and the wall cannot be installed, and achieve the effects of reducing contact, convenient and convenient installation, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

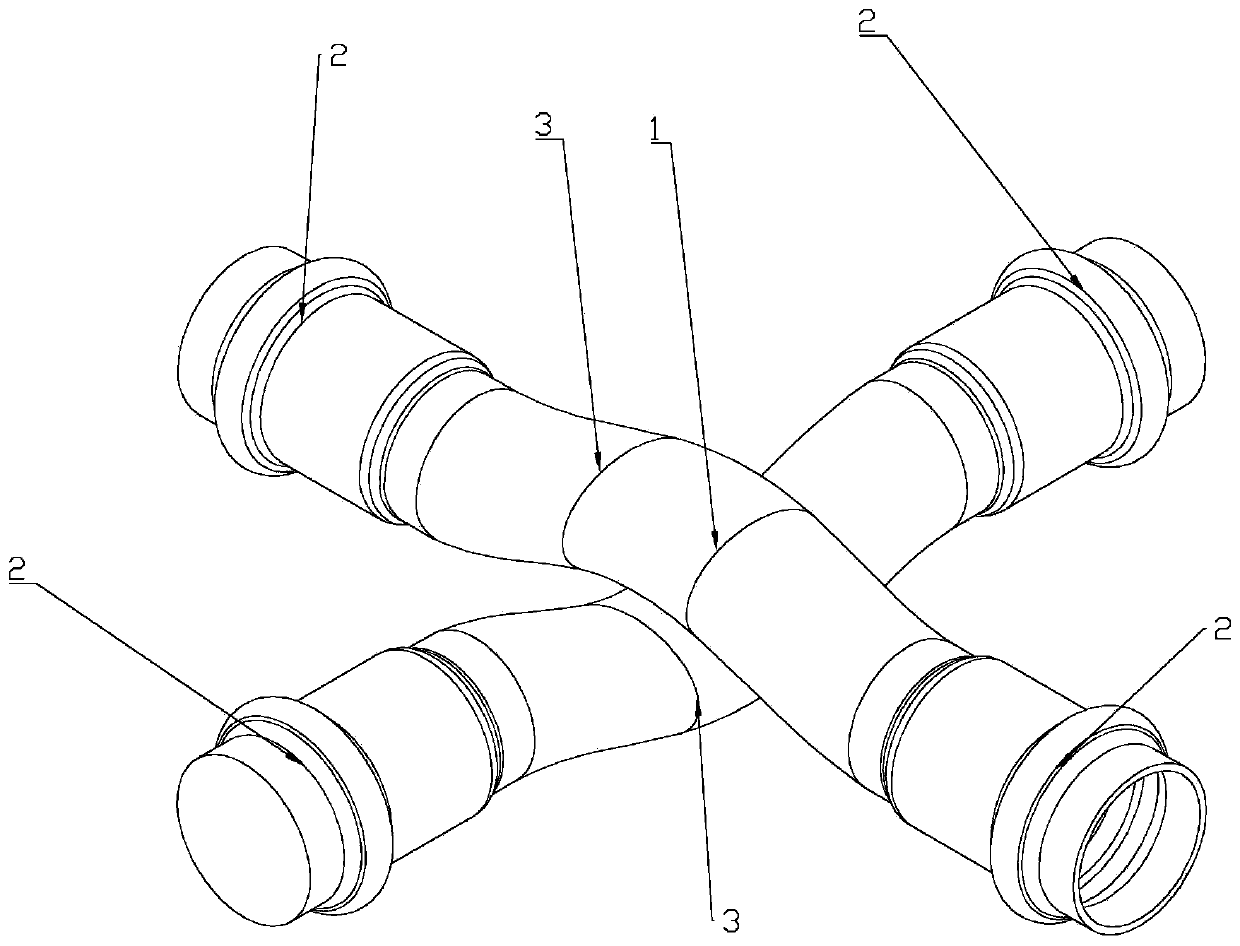

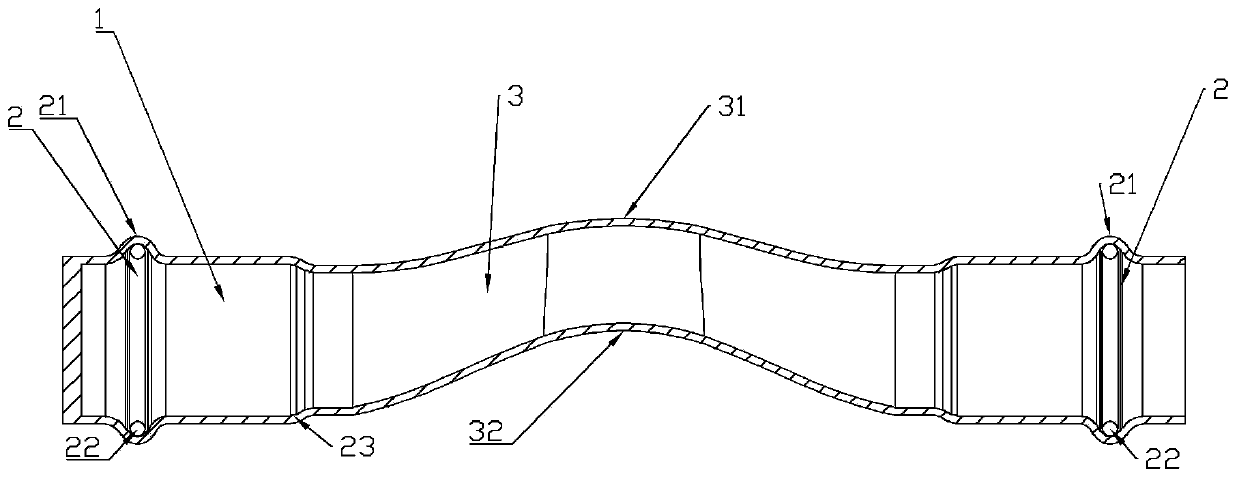

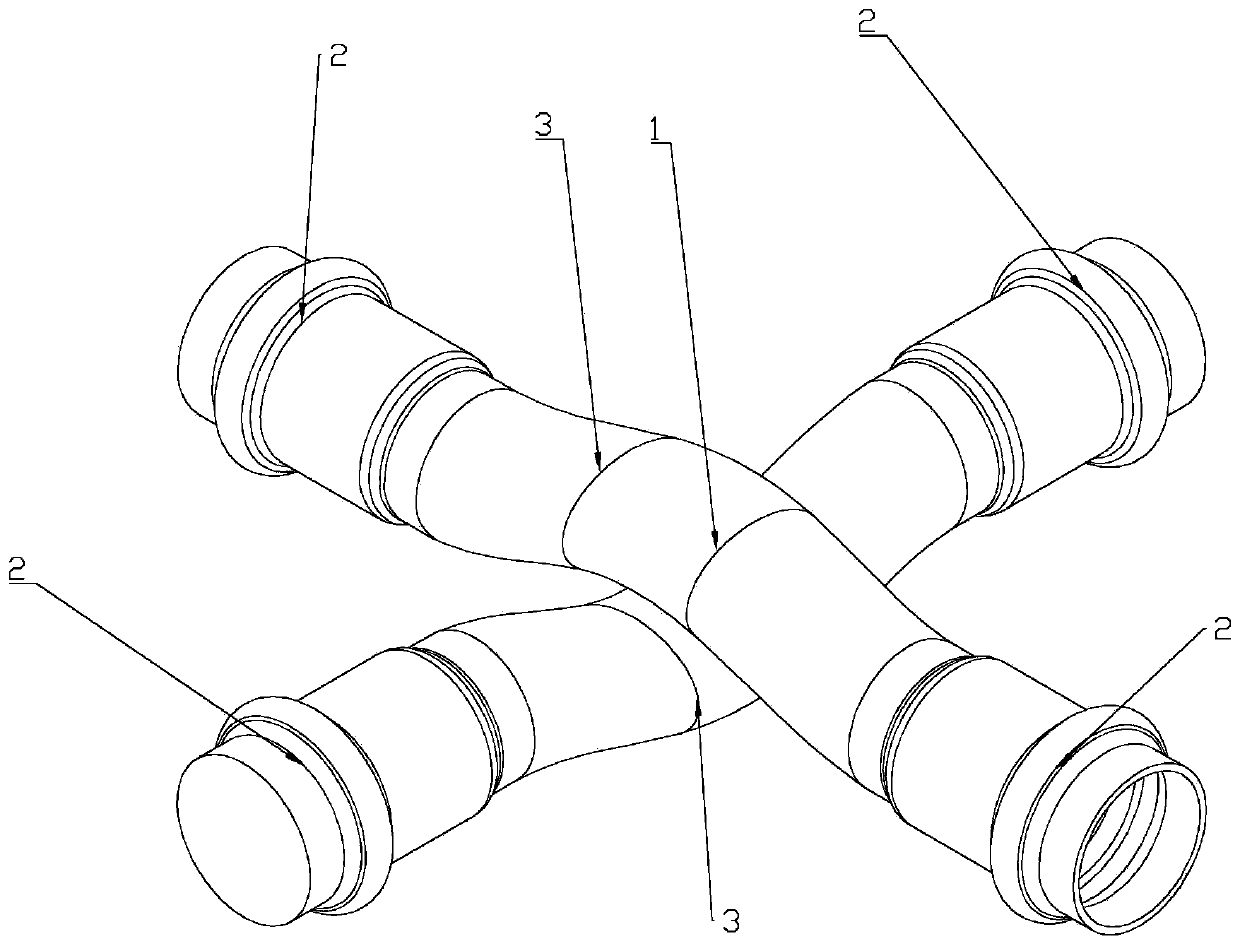

[0030] see Figure 1~2 , a bridge piece, including pipe fittings 1 used in pairs, both ends of the pipe fittings 1 are compression joints 2, the middle part of the pipe fitting 1 is a curved part 3 that is bent to one side as a whole, and the bending directions of different pipe fittings 1 are opposite .

[0031] The pipe fittings 1 used in pairs can reduce the contact of adjacent pipes when the pipes cross, and the pipe fittings 1 used in pairs can reduce the overall curvature of the bridge, and can also be used on thinner walls; And the setting of the pressing joint 2 makes the installation more convenient and convenient.

[0032] The curved part 3 includes an upper arch point 31 and a lower arch point 32, the upper arch point 31 is higher than the outer diameter of the compression joint 2 and lower than 1.5 times the outer diameter of the compress...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap