System and method for leakage detection of fuel evaporation system

A fuel evaporation system, leak detection technology, applied in the direction of measuring the acceleration and deceleration rate of fluid, using liquid/vacuum degree for liquid tightness measurement, measuring device, etc. Emissions, inability to determine leak size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not used to limit the present invention.

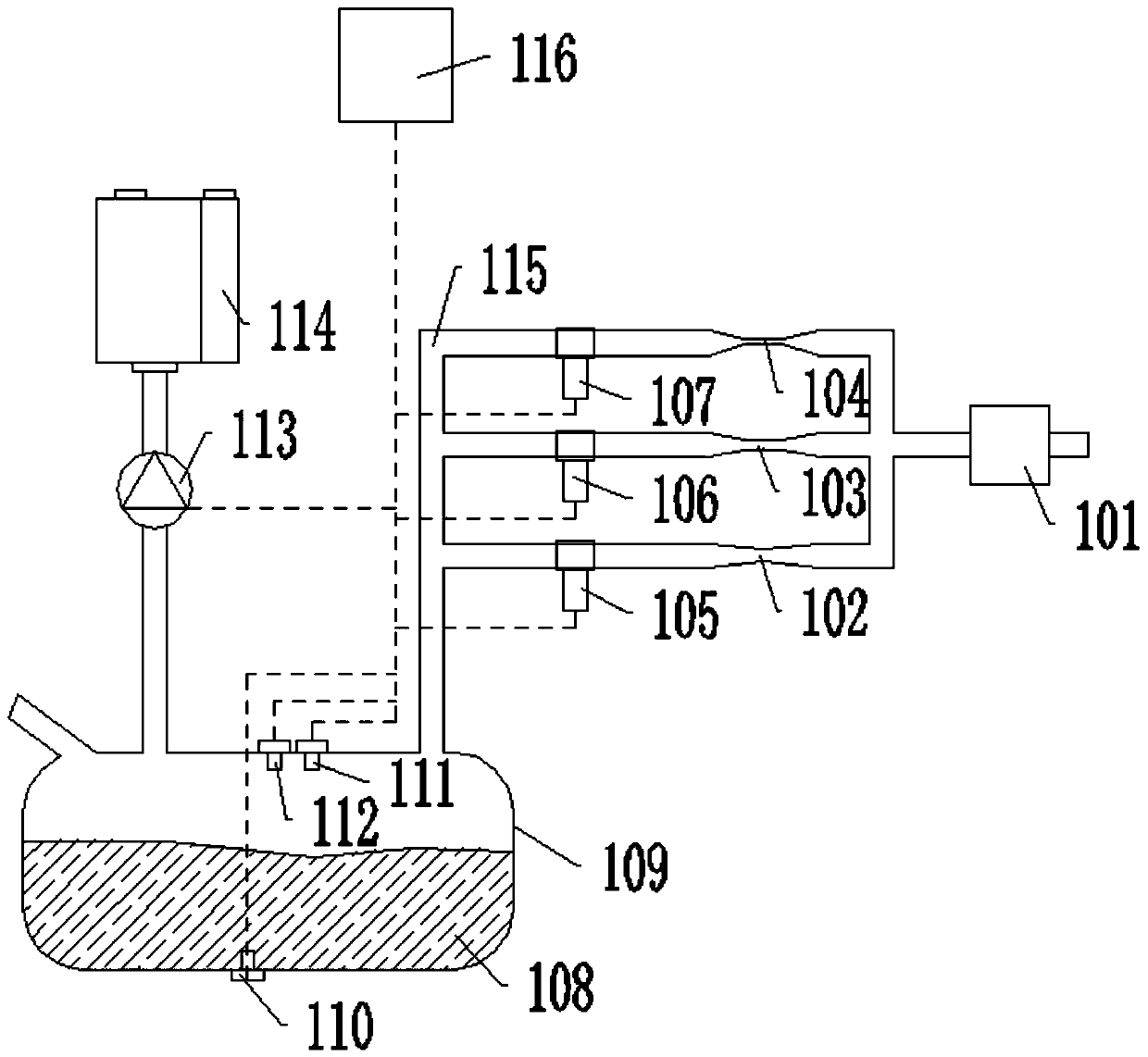

[0025] Such as figure 1 As shown, the present invention discloses a calibration system for fuel evaporation system leakage detection. A temperature sensor 111 and a pressure sensor 112 are installed on the top of a sealed reference fuel tank 109, and a liquid level sensor 110 is installed on the bottom of the sealed reference fuel tank 109, and The sealed reference oil tank controller 116 is respectively connected, and the measured temperature data, pressure data, and liquid level data of the gas in the sealed reference oil tank 109 are transmitted to the sealed reference oil tank controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com