A test chamber for measuring the variation of pulverized coal deposition with ballast depth

A technology of depth change and test chamber, applied in the direction of analyzing materials, instruments, etc., to achieve the effect of simple and practical structure, convenient movement and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

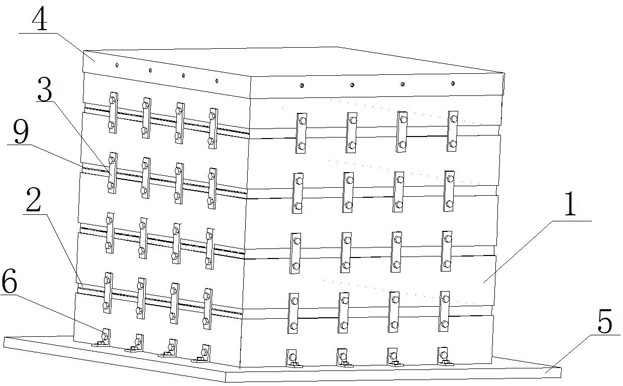

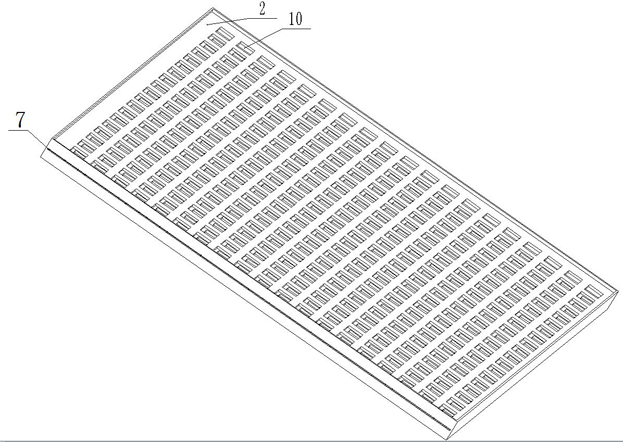

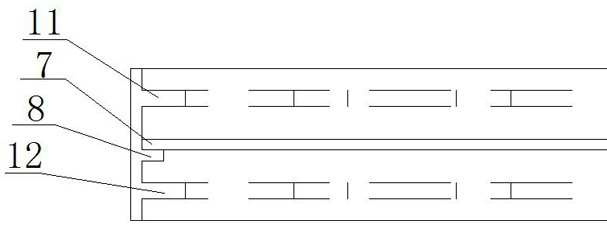

[0022] Such as figure 1 , figure 2 As shown, a test box for measuring the variation of pulverized coal deposition with the ballast depth includes an upper cover 4, a box body and a base 5. Bolt fixing holes are arranged around the upper cover 4, and the box body includes four layers of vertically connected screens. Box 1, screen box 1 includes a cylinder wall 13 and a sieve plate 2, the sieve plate 2 is located at the bottom of the cylinder wall 13, the cylinder wall 13 and the sieve plate 2 are sealed and connected, and the side of the sieve plate 2 is provided with an insert for the insert plate 9 to enter and exit. Hole 7, the bottom end of the lowermost cylinder wall 13 of the test box is sealed and connected with the base 5; during the test, the test box is fixed on the vibration table, there is no insert plate 9 in the jack hole 7, and the uppermost screen box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com