Automatic pose adjustment method and device for spherical optical element with large curvature radius

A spherical optics, pose adjustment technology, applied in electrical components, measuring devices, optical testing flaws/defects, etc., can solve the problems of image plane defocusing, sub-aperture image defocusing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

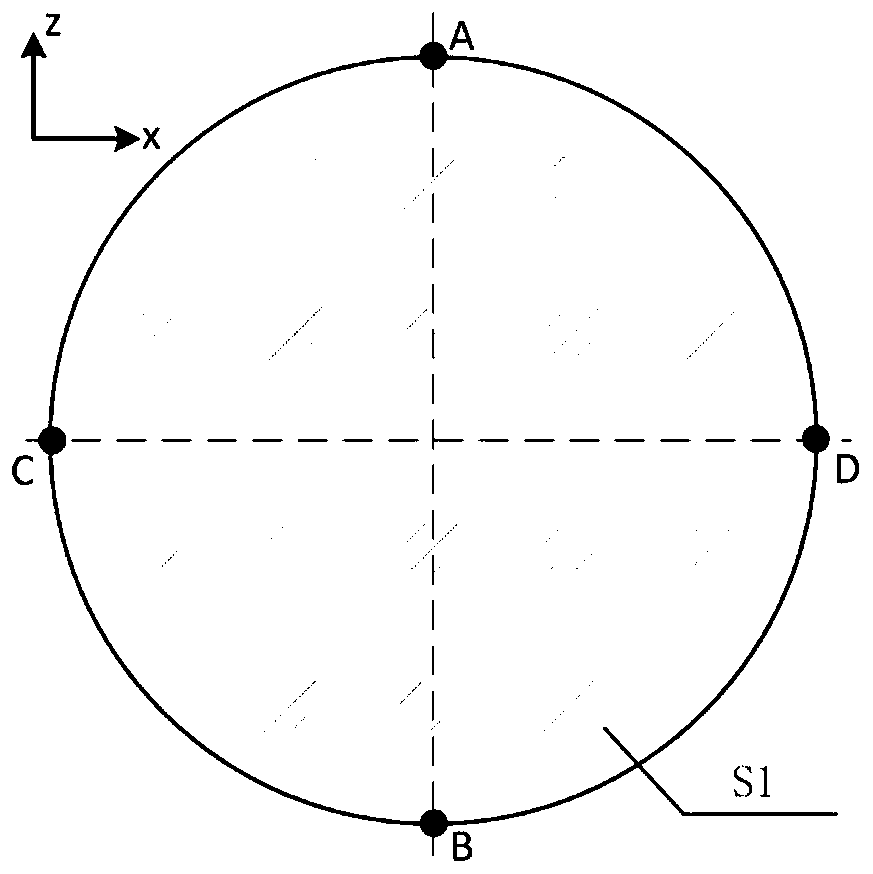

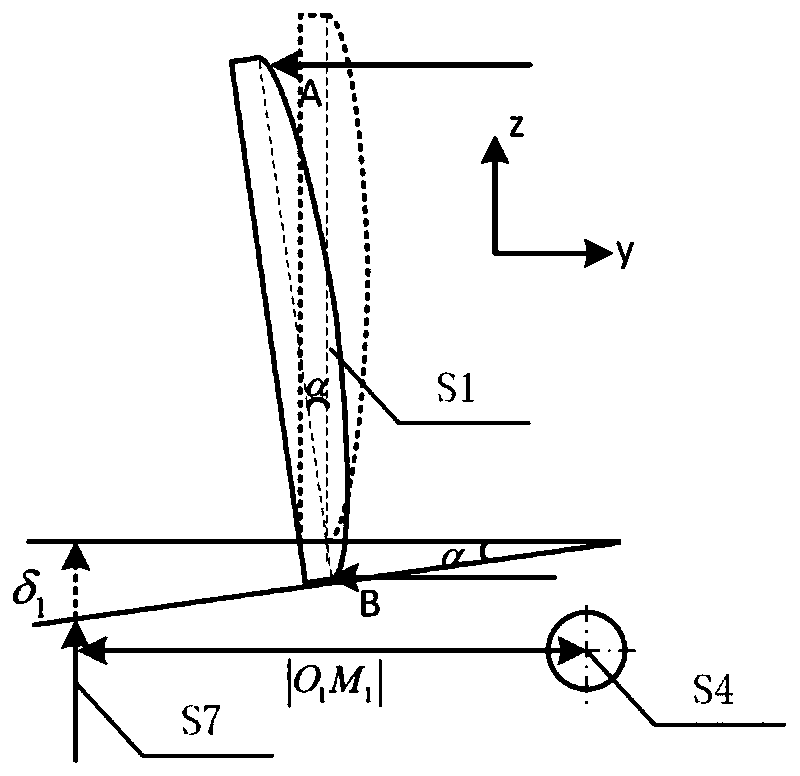

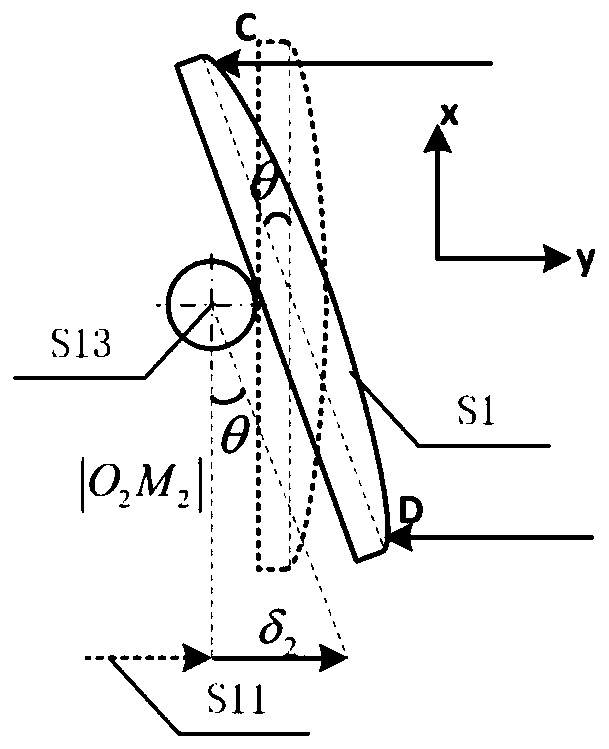

[0090] Select the diameter of the spherical optical element as The radius of curvature R=4m, so the center-to-edge sagittal height is calculated to be h=6.3mm, and the selected microscope has a depth of field of 6mm at low magnification, which cannot cover the entire aperture range of the spherical element, so it is necessary to automatically adjust its pose and use focus The continuous feedback compensation of the guide rail in the Z direction realizes the control of the constant working distance of the microscope, and then carries out the sub-aperture "back" scanning acquisition, and obtains a clear and fully-focused full-aperture image.

[0091] Using a high-power microscope at 16 times and a CCD camera to continuously collect 20 dark-field grayscale images with a step size of 0.01mm on the surface feature point A, Figure 7 Shown is a partial image of the collected surface feature points; these 20 images are calculated by the Tenengrad operator, and the relationship betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com