Camera focus control device

A lens and frame technology, applied in the lens field, can solve problems such as lack of precision fine-tuning, difficult cam structure, and inability to meet focus adjustment requirements, and achieve the effects of reducing labor intensity, simple and convenient assembly, and reducing the probability of assembly errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

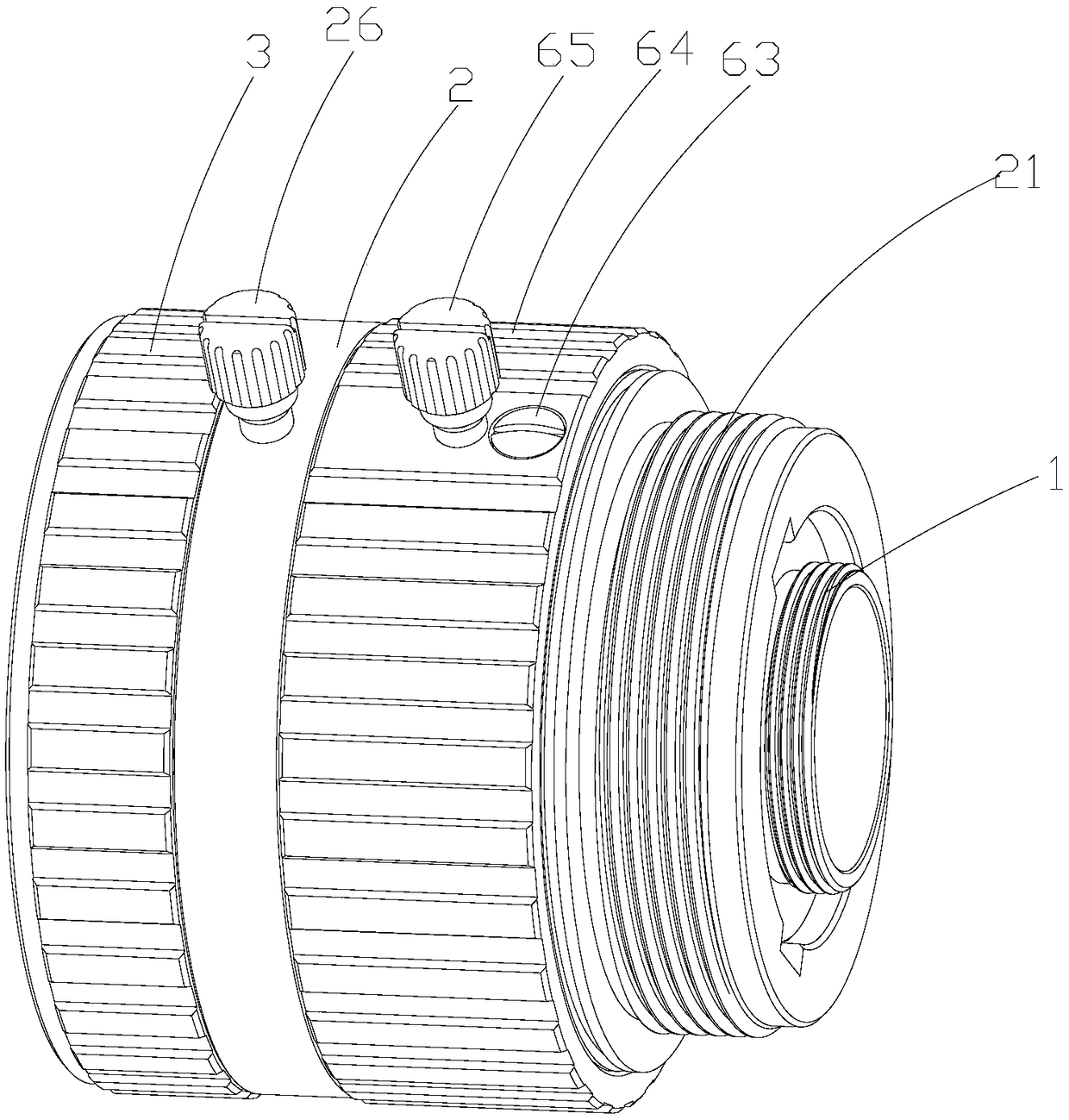

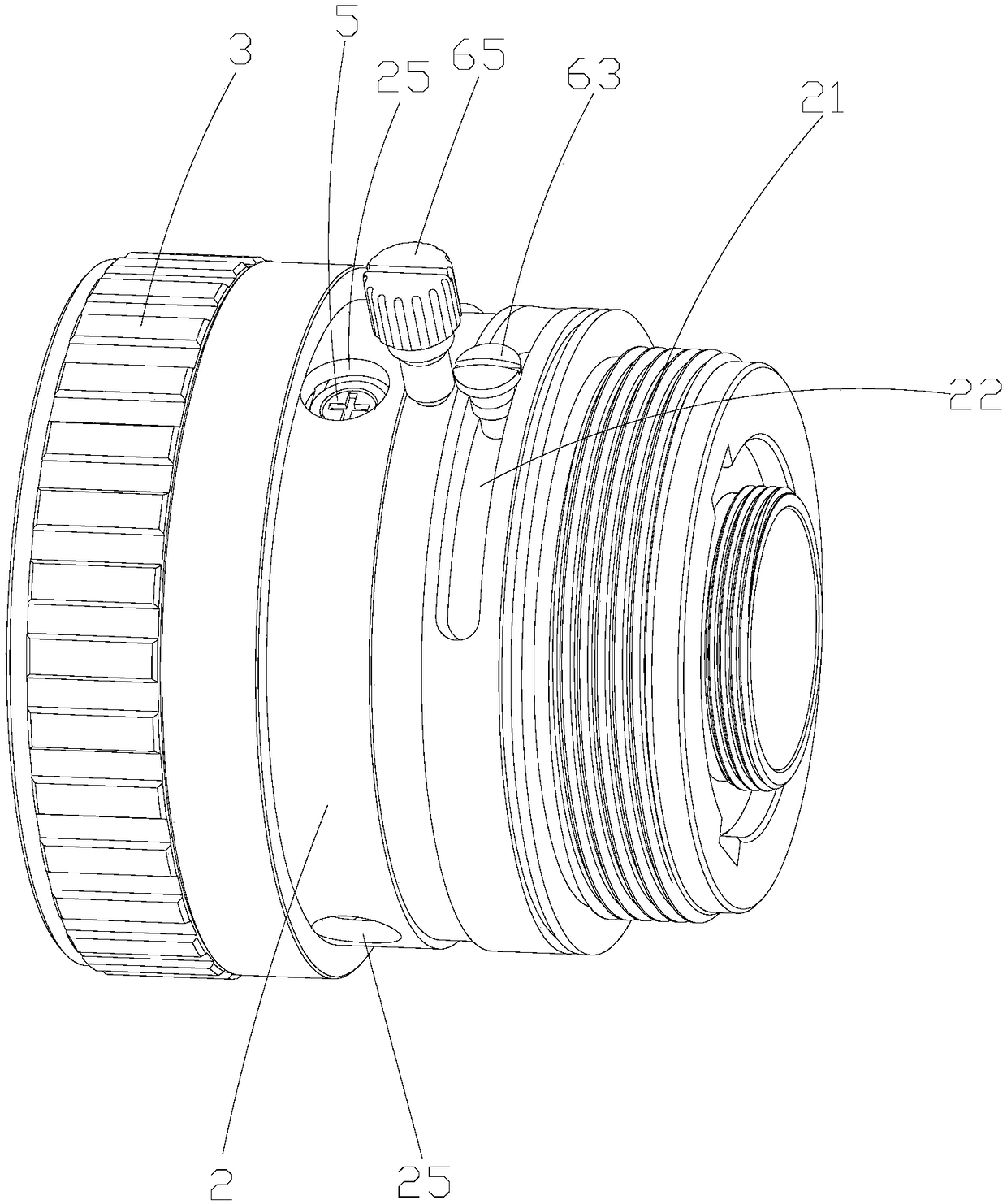

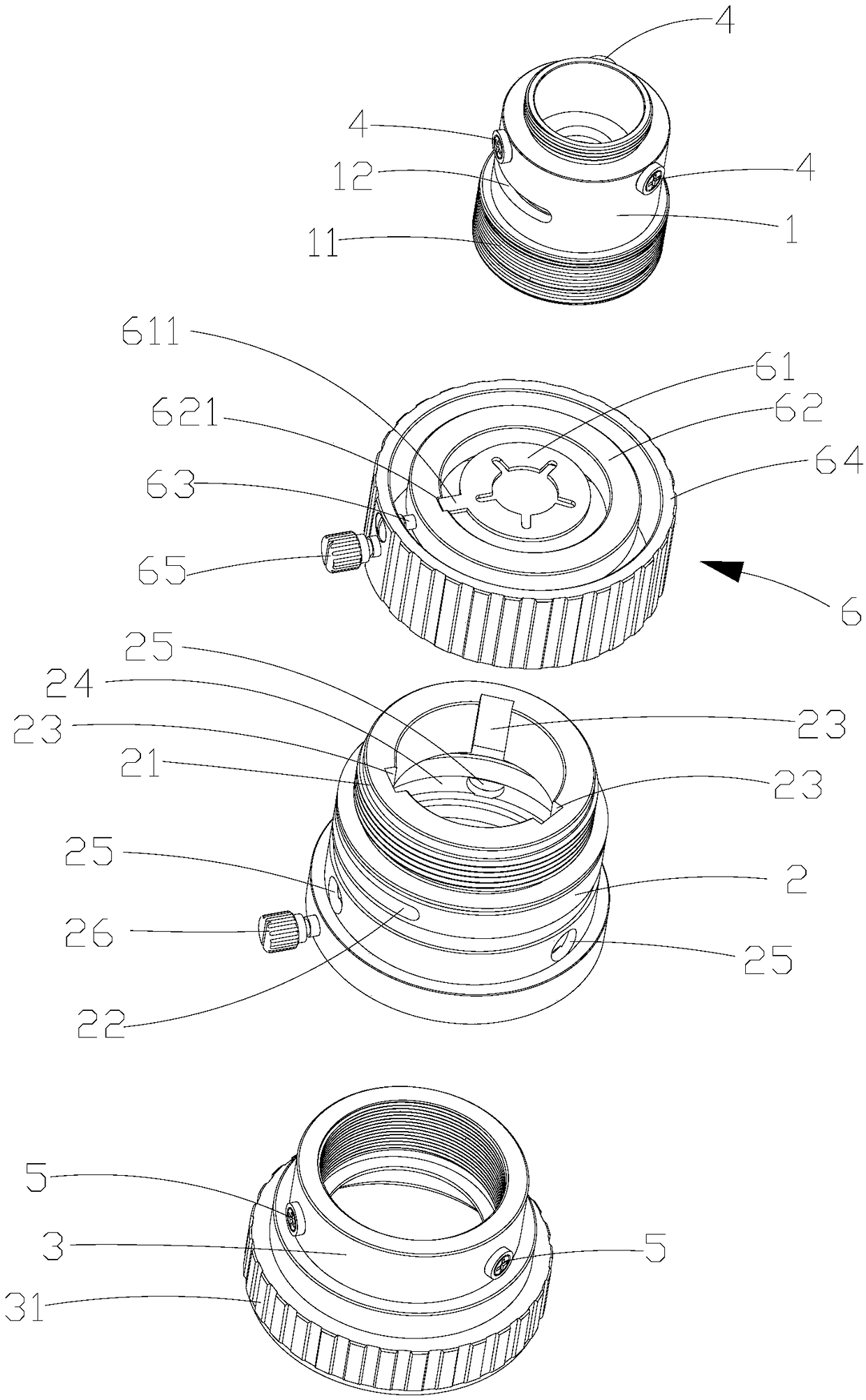

[0036] Please refer to attached figure 1 to attach Figure 6 , in an embodiment of the present invention, a lens focusing device includes a frame 1, a main barrel 2 and a frame adjustment ring 3, a frame threaded portion 11 is provided on the outer periphery of the front end of the frame 1, and the frame 1 is adjusted with the frame through the threaded portion 11 of the frame. The ring 3 is threaded, the frame 1 and the frame adjusting ring 3 are set in the main tube 2, and the frame 1 and the main tube 2 are restricted by the first stopper 4 between the frame 1 and the main tube 2 to move back and forth in the axial direction relative to the main tube 2 Instead of being able to rotate in the circumferential direction relative to the main cylinder 2, the frame adjustment ring 3 and the main cylinder 2 are restricted by the second limiter 5 between the frame adjustment ring 3 and the main cylinder 2. To move back and forth, the outer circumference of the end of the main cylin...

Embodiment 2

[0049] The difference between this embodiment and Embodiment 1 is that in this embodiment, the first limiting member 4 is connected and arranged on the inner surface of the main cylinder 2, and the mirror frame 1 is provided with an axial straight line that matches the first limiting member 4. The first stopper 4 restricts the mirror frame 1 to only move back and forth relative to the main cylinder 2 along the axial straight groove but not to rotate circumferentially relative to the main cylinder 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com