Method for determining carbonization depth of orthogonal laminated wood floor slab under condition of laminate falling

A determination method and technology of glulam, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve the problems of carbonization speed change, layer shedding, complex carbonization depth calculation, etc., to achieve the effect of accurate carbonization depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

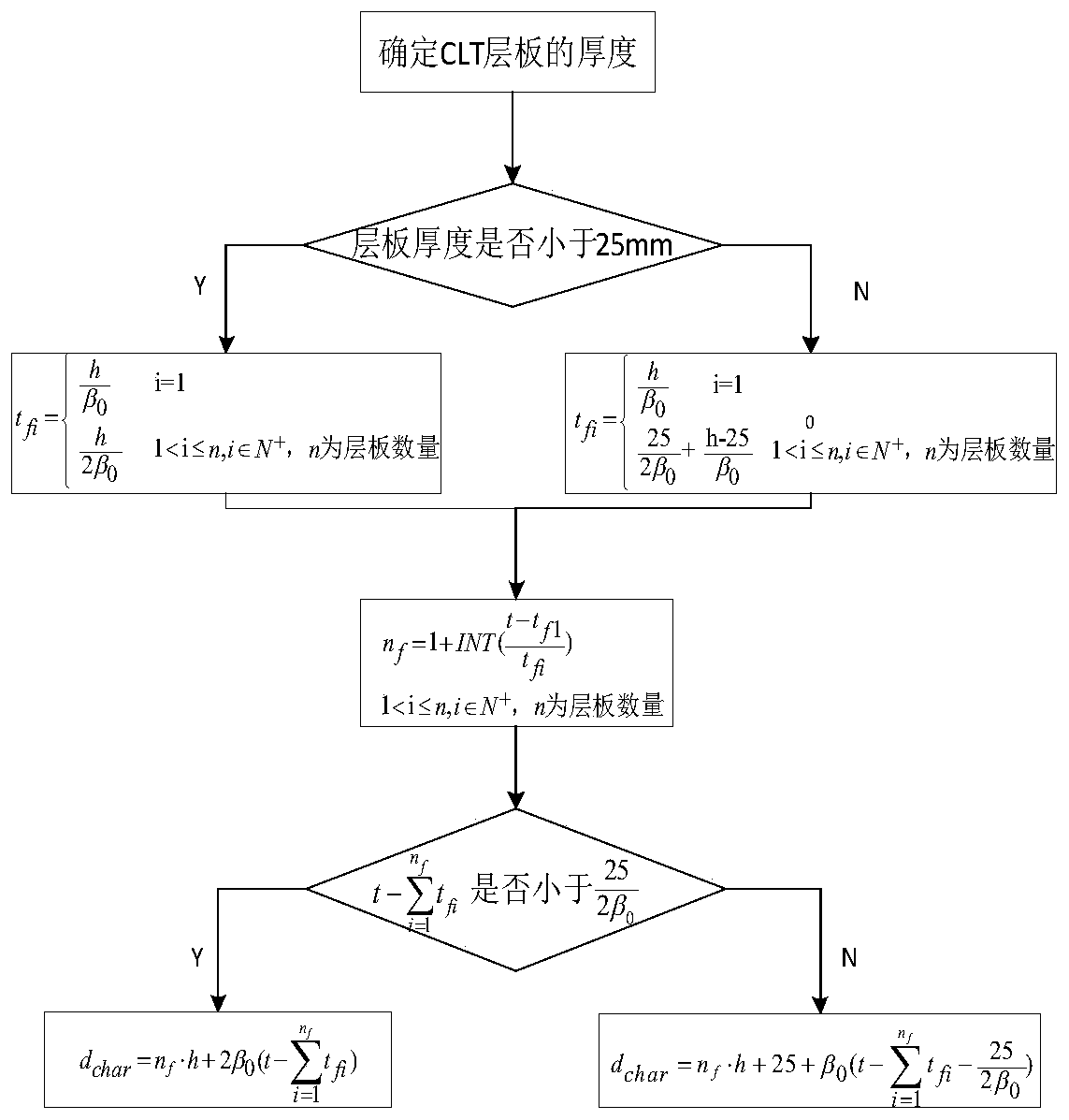

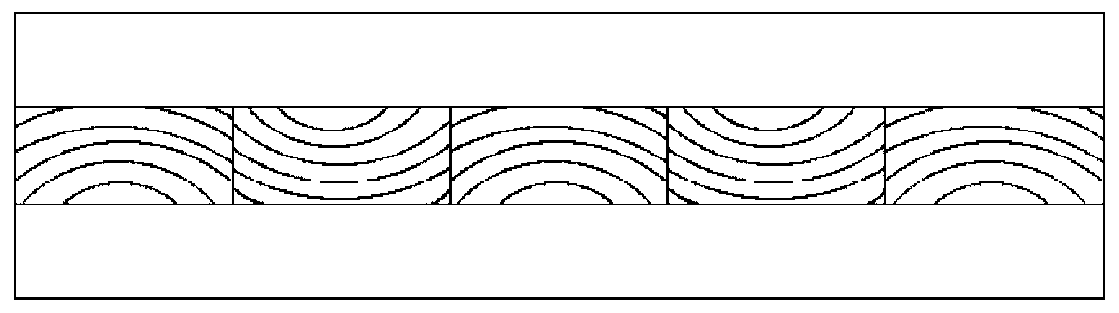

[0037] A three-layer cross-glued wood board with a fire exposure time of 75 minutes and a laminate thickness of 35 mm is selected for carbonization depth calculation. The cross-sectional dimensions are as follows: image 3 shown.

[0038] 1. Compare the thickness h of the CLT laminate with 25mm;

[0039] 2. Comparing the thickness of the laminate with 25mm, calculate the time t required for carbonization of each laminate fi :

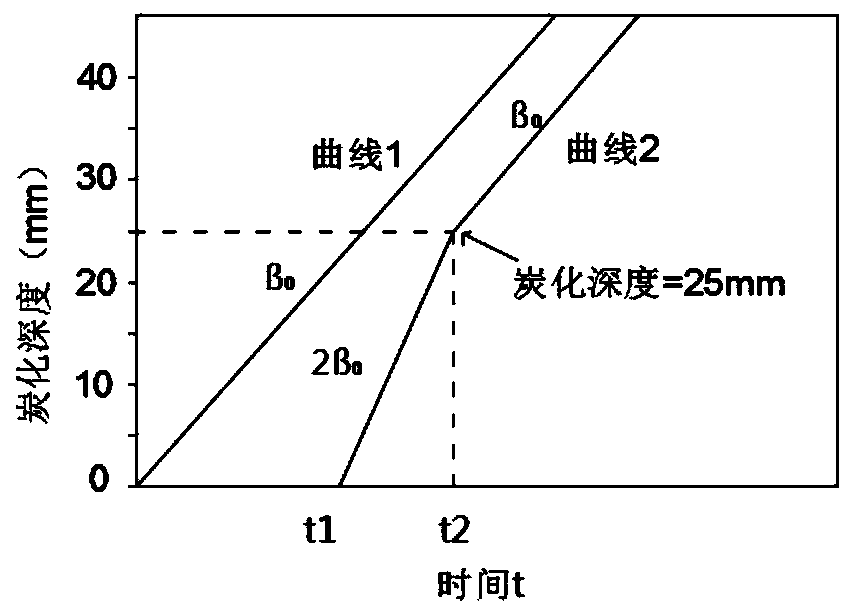

[0040] The thickness of the laminate is greater than 25mm, and the carbonization speed of the first laminate is β 0 (0.65mm / min), the carbonization speed of subsequent laminates is maintained at 2β before the carbonization depth of the laminates reaches 25mm 0 remains unchanged, when the carbonization depth reaches 25mm, the carbonization speed decreases to β 0 , and maintain this carbonization speed to continue carbonization until the layers fall off.

[0041]

[0042] 3. According to the fire exposure time t and the time t required for carboni...

Embodiment 2

[0050] A five-layer cross-glued wood board with a fire exposure time of 75 minutes and a laminate thickness of 21 mm is selected for carbonization depth calculation. The cross-sectional dimensions are as follows: Figure 4 shown.

[0051] 1. Compare the thickness h of the CLT laminate with 25mm;

[0052] 2. Comparing the thickness of the laminate with 25mm, calculate the time t required for carbonization of each laminate fi :

[0053] The thickness of the laminate is less than 25mm, and the carbonization speed of the first laminate is β 0 (0.65mm / min), the carbonization speed of subsequent laminates is maintained at 2β 0 Unchanged, when the carbonization depth reaches 21m, the laminate occurs.

[0054]

[0055] 3. The fire time t of the root and the carbonization time t of each laminate fi , to calculate the shedding number of laminates during the fire exposure process:

[0056]

[0057] 4. Will and Compare the size and calculate the carbonization depth:

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap