A data-driven optimization method for petrochemical enterprise planning

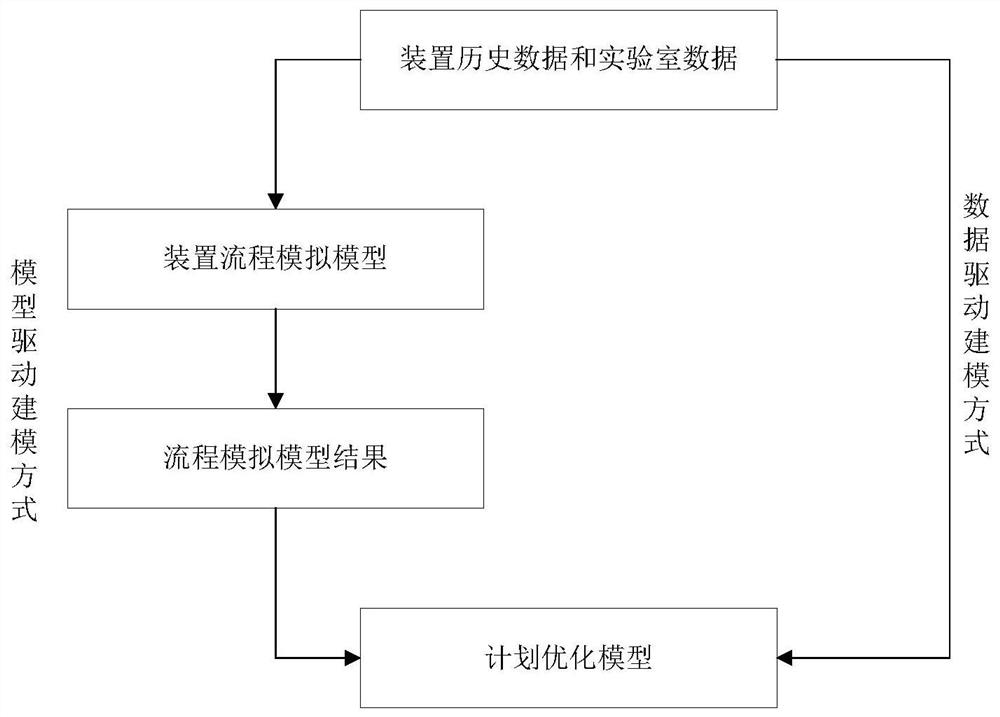

A data-driven, optimization method technology, applied in data processing applications, calculations, predictions, etc., can solve the problem of inability to accurately optimize the cutting temperature point of atmospheric and vacuum devices, and achieve the effect of solving manual dependence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention is further described below in conjunction with specific embodiment, but protection scope of the present invention is not limited thereto:

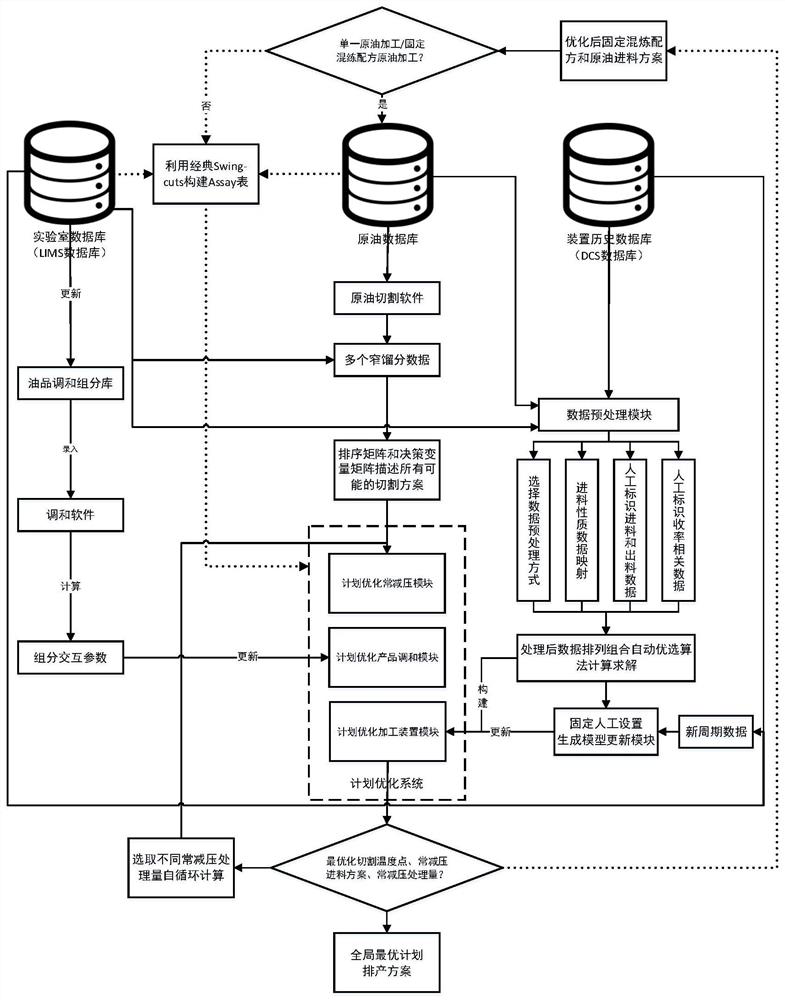

[0054] Embodiment: Taking the construction process of a refinery plan optimization model in Shandong as an example, such as figure 2 As shown, a data-driven petrochemical enterprise planning optimization method includes the following steps:

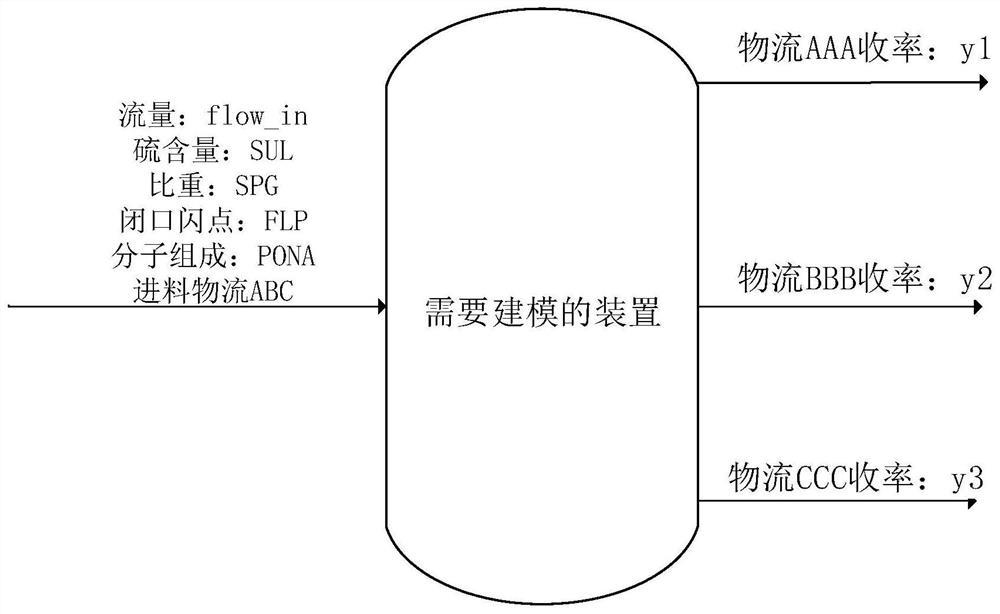

[0055] (1) Comprehensively count the properties in the crude oil database purchased by the refinery, the properties required for plan optimization, the properties involved in the Chinese crude oil evaluation standard test method and the product oil evaluation standard test method, and establish the property library required for the plan optimization model. In particular, due to the limitations of the refinery’s own analysis and detection technology, some properties did not appear in the actual production data of the refinery. The properties that were not involved in this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com