In-situ failure analysis sample table and scanning electron microscope

A failure analysis sample and in-situ technology, which is applied to the analysis of materials, material analysis using wave/particle radiation, circuits, etc. The effect of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

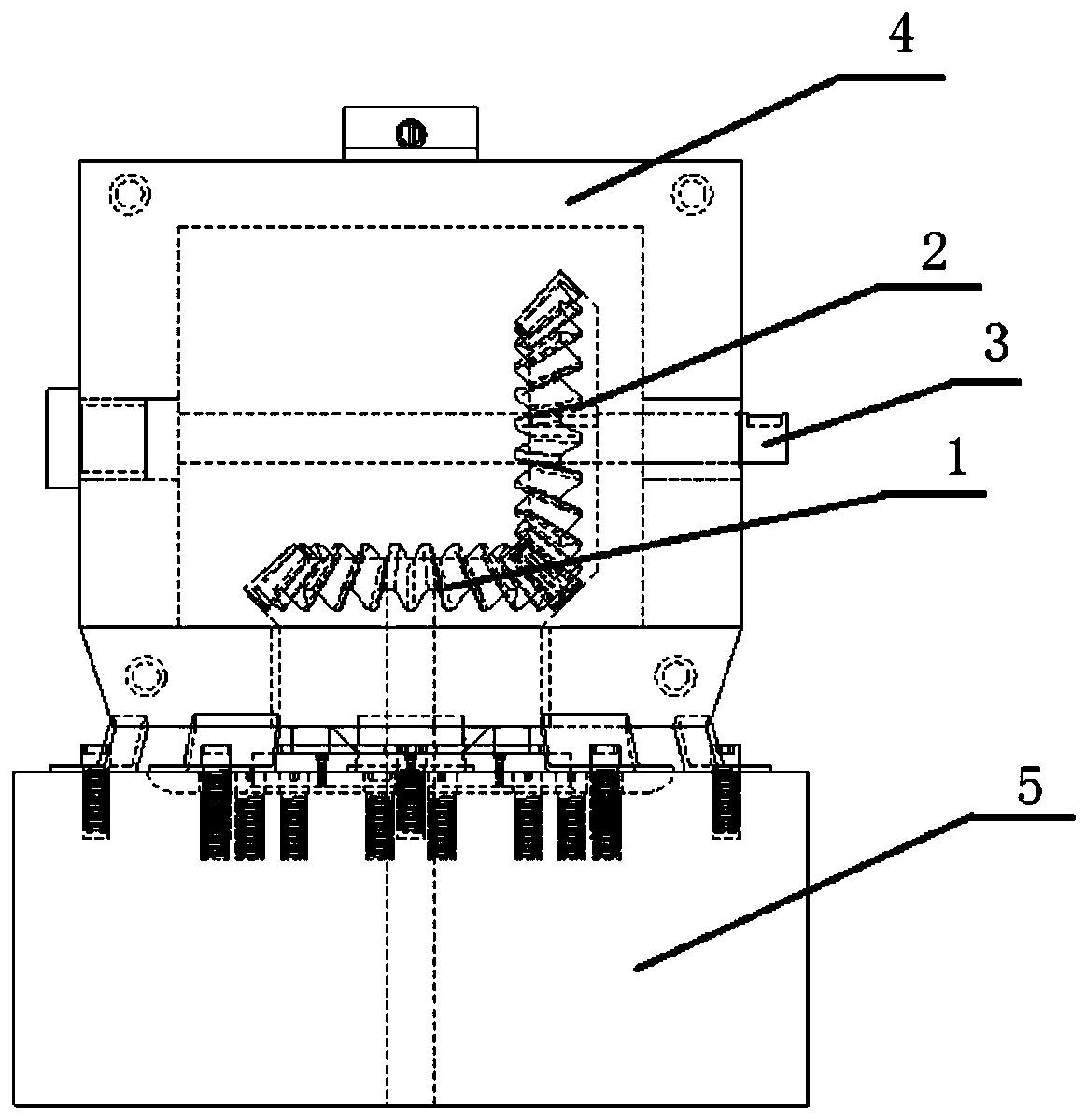

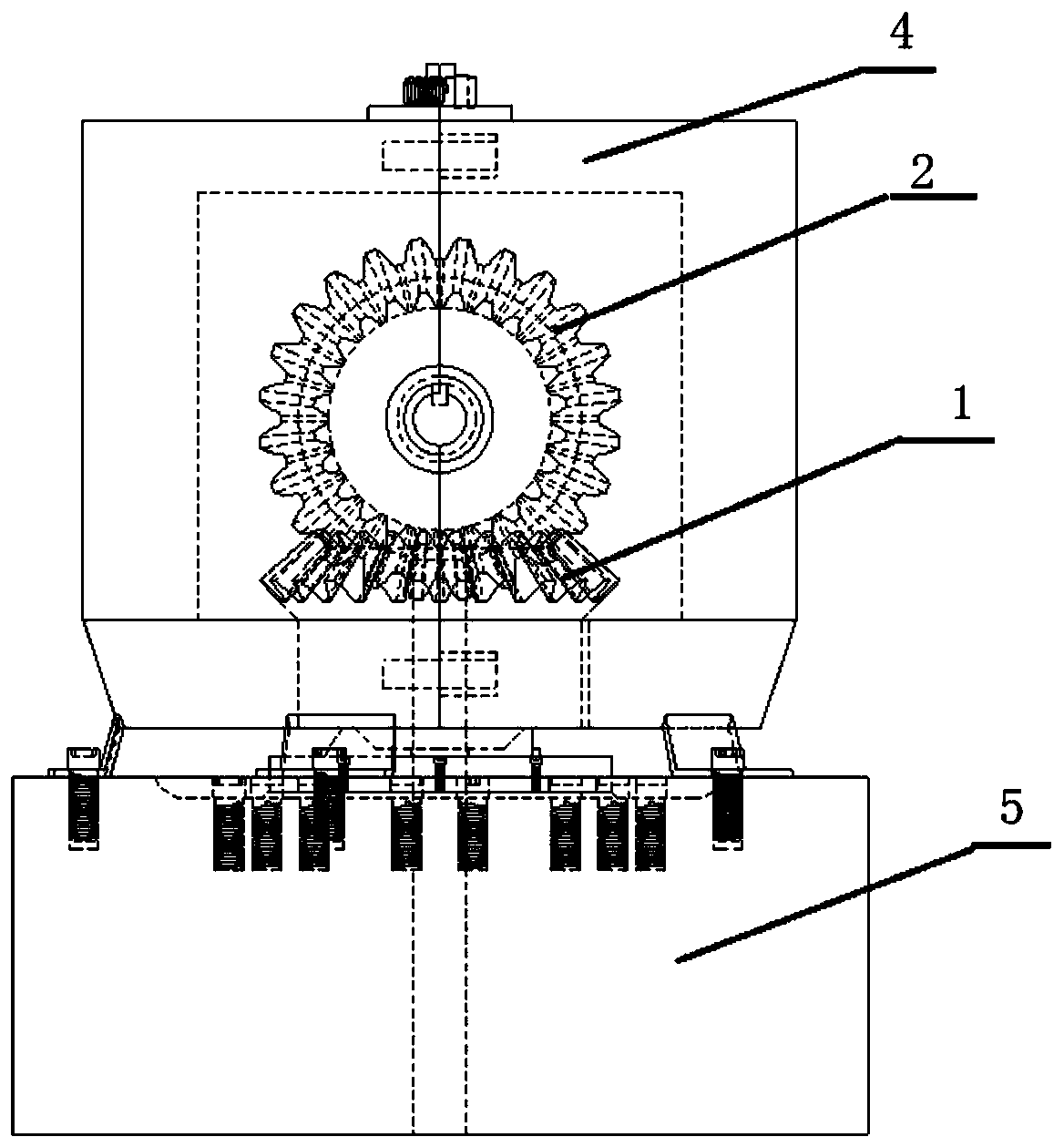

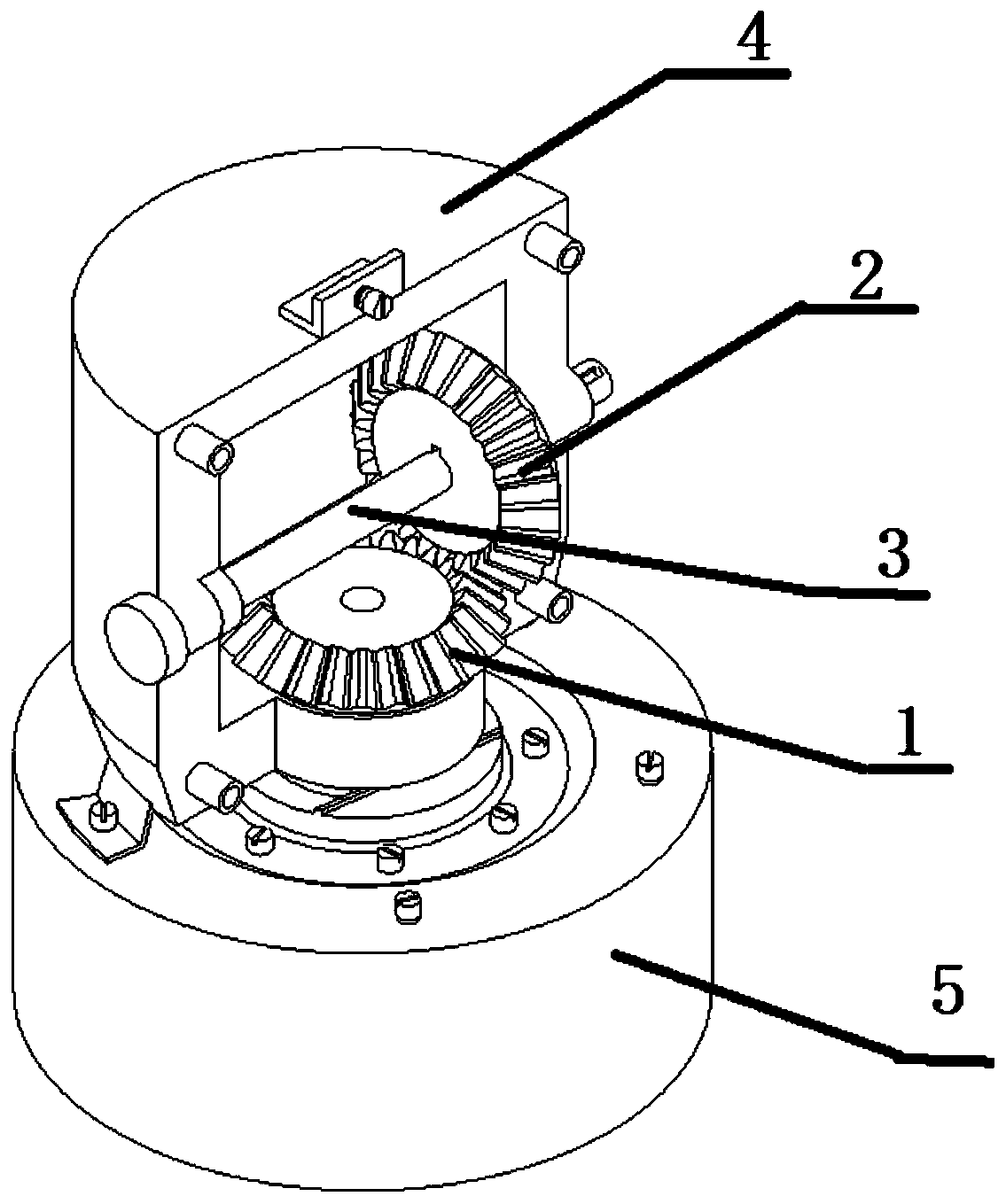

[0039] As an embodiment, the scanning electron microscope in-situ failure analysis sample stage further includes:

[0040] The supporting part is used for supporting the reversing part.

[0041] As an optional embodiment, the support part is formed by fixed connection of two support structures 4 with the same structure.

[0042] It can be understood that the support structure can be fixed by means of screw fixing or clamping, and those skilled in the art can specifically select a fixing connection method according to actual conditions.

[0043] Specifically, such as Figure 4 As shown, the support structure 4 includes a bottom 6 and a side wall 7, the bottom 6 is provided with a semicircular notch 8, the radius of the semicircular notch 8 is greater than the radius of the first bevel gear 1; the side wall 7 is fixed on the bottom , both end surfaces of the side wall 7 are provided with at least one groove 9 for supporting the second gear shaft 3 .

[0044] The radius of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com