Automatic removal processing system and method for rubber caps of lead-acid batteries

A processing system, lead-acid battery technology, applied in lead-acid battery, lead-acid battery construction, battery cover/end cover, etc., can solve the problem of automatic removal of the battery cover rubber cap, etc., and achieve the consistency of formed pole holes Good, fast cap removal, high degree of automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

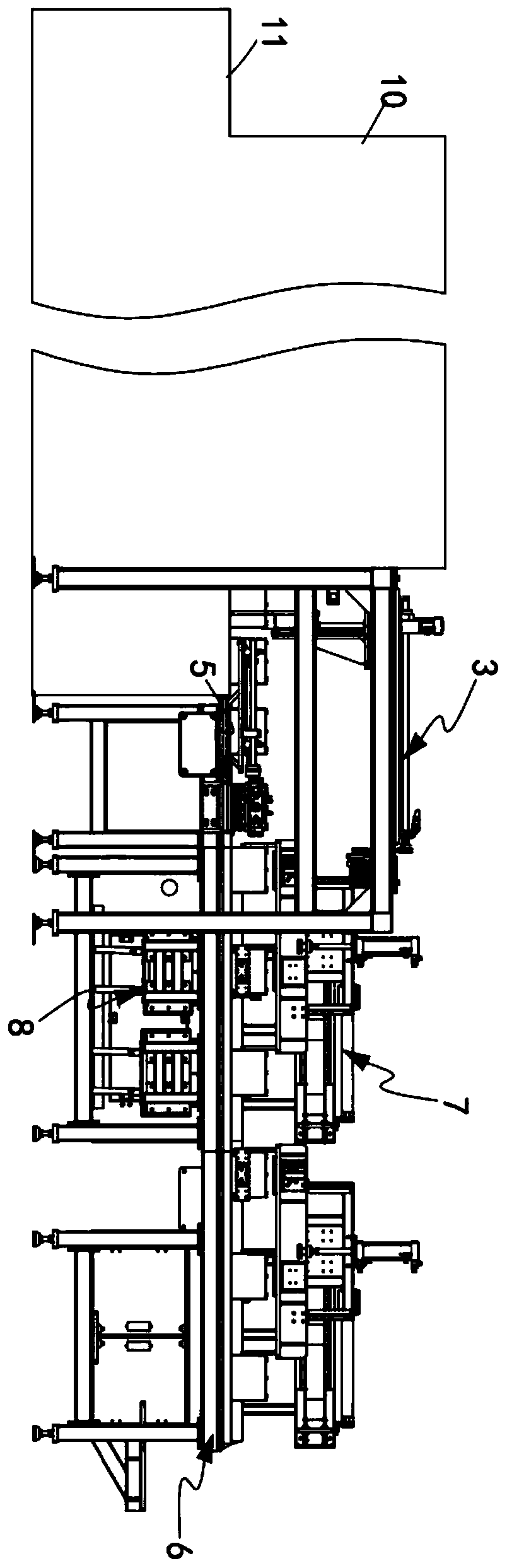

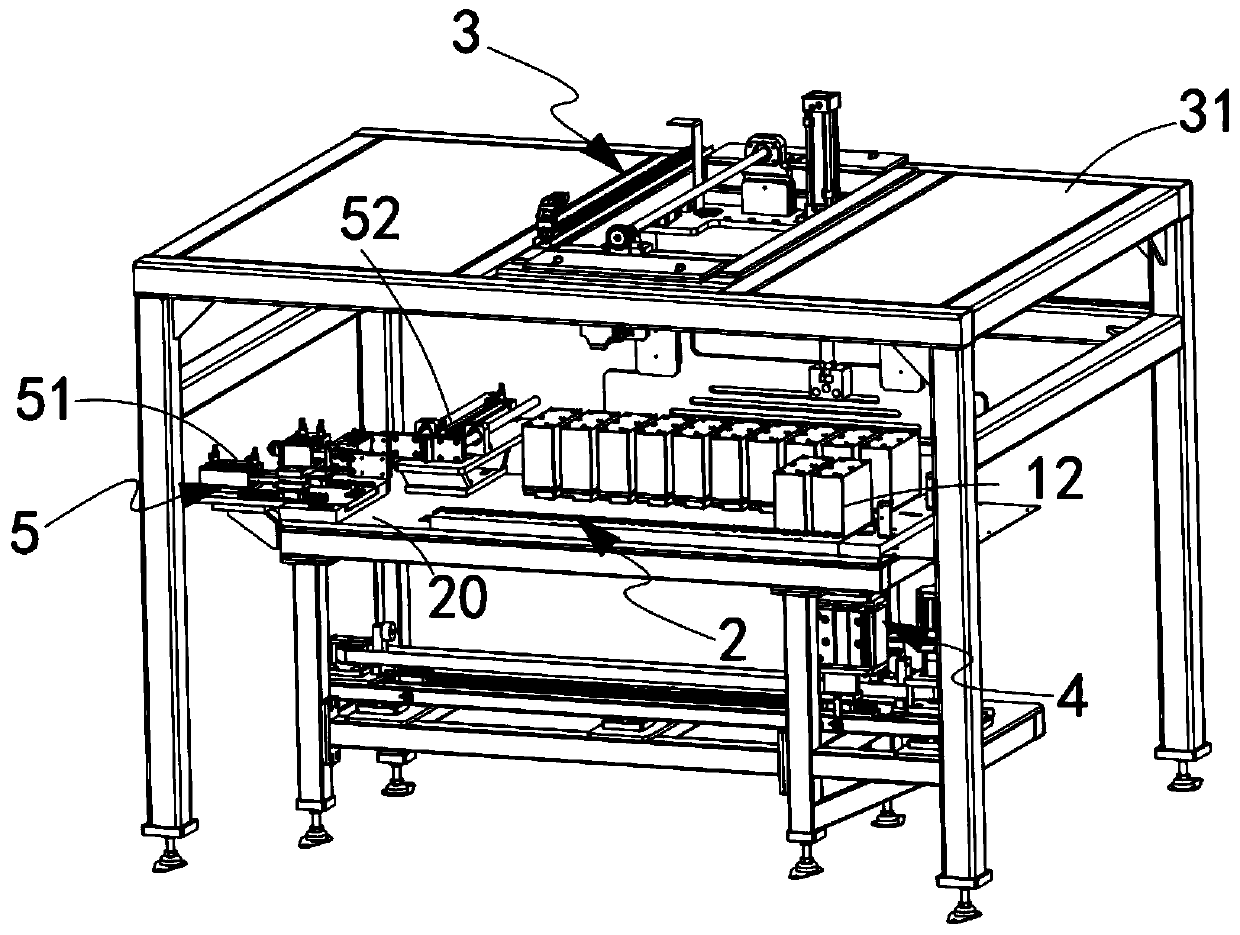

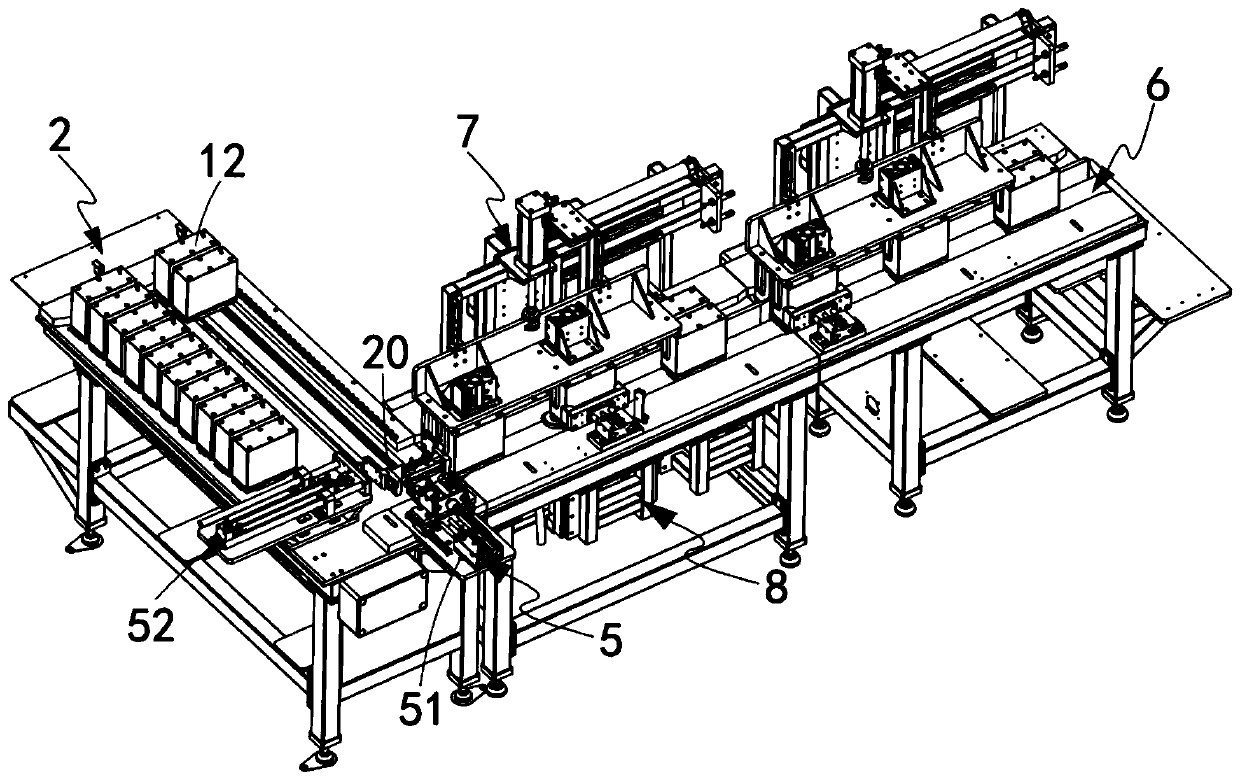

[0087] Such as Figure 1 to Figure 3 As shown, an automatic processing system for removing rubber caps of lead-acid batteries includes an oven 10 and a conveyor line 11 that penetrates the oven 10. The conveyor line 11 conveys batteries 12 that are arranged in a square array and are inverted. include:

[0088] Transitional material distribution platform 2, said transitional material distribution platform 2 is connected to the output end of said conveying line 11;

[0089] Transitional material shifting assembly 3, said transitional material shifting assembly 3 is arranged directly above said transitional distributing table 2, and said battery 12 transported on said conveyor line 11 is shifted by said transitional material shifting assembly 3 , Transfer to the transitional distribution table 2 in rows along the width direction of the conveying line 11;

[0090] The distributing assembly 4, the distributing assembly 4 is arranged directly below the transition distributing table 2, and...

Embodiment 2

[0142] With reference to the first embodiment, a processing method for automatically removing the rubber cap of a lead-acid battery in the second embodiment of the present invention is described.

[0143] Such as Figure 21 As shown, a processing method for automatically removing the rubber cap of a lead-acid battery includes the following steps:

[0144] Step one, drying and outputting, the inverted batteries 12 are arranged in a square array and equidistantly arranged through the oven 10 through the conveyor line 11, and are baked in the oven 10 and output through the conveyor line 11;

[0145] Step 2: Transitional shifting. The rows of equidistantly arranged batteries 12 on the output end of the conveying line 11 are driven by the shifting drive group 33 above the conveying line 11 to drive the lowering shifting plate 32 to be behind the conveying line 11 Transitional distribution table 2 on the side;

[0146] Step three, divide the material, transfer to the battery 12 on the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com