Liquid cooling plate support buffer structure and battery pack

A buffer structure and liquid-cooled plate technology, which is applied to secondary batteries, structural parts, battery pack parts, etc., can solve the problems of poor support structure stability, uneven overall force, deformation and leakage, and improve stability and service life, reduce the risk of deformation leakage, slow recovery of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

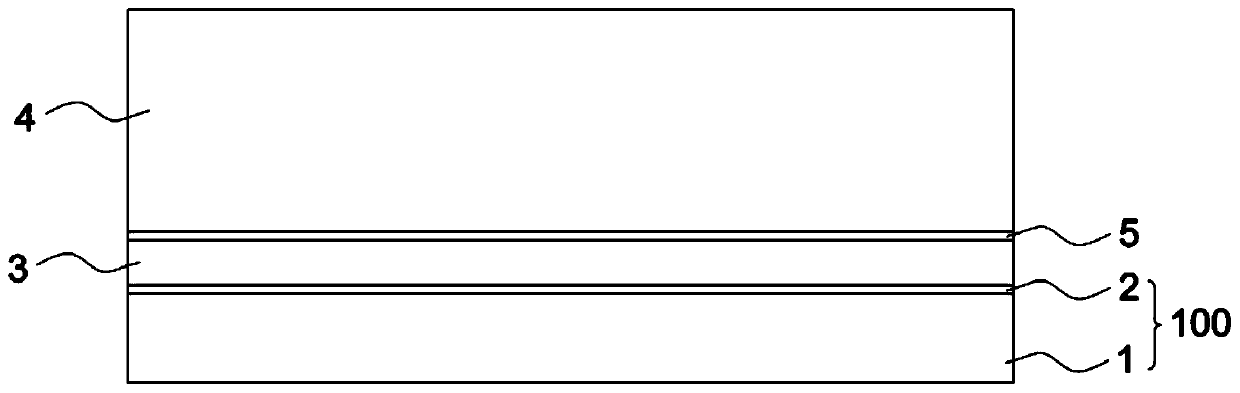

[0041] This embodiment provides a liquid-cooled plate support and buffer structure 100, which is located between the liquid-cooled plate 3 and the battery pack box (not shown in the figure), and plays a role of supporting and buffering the liquid-cooled plate 3, and can The stability of the battery pack 4 is effectively improved.

[0042] like figure 1 As shown, the liquid-cooled plate support and buffer structure 100 includes an elastic heat-insulating support part 1, one end of the elastic heat-insulated support part 1 is in contact with the liquid-cooled plate 3, and the other end is arranged at the bottom of the battery pack box. In this embodiment, the elastic heat insulation support part 1 and the liquid cooling plate 3 may be in direct surface contact, or may be glued together. Optionally, a first connection part 2 is provided between the elastic heat insulation support part 1 and the liquid cold plate 3 , and one end of the elastic heat insulation support part 1 is bo...

Embodiment 2

[0049] The second embodiment provides a liquid-cooled plate support and buffer structure 100. The main difference between the liquid-cooled plate support and buffer structure 100 and the liquid-cooled plate support and buffer structure 100 in Embodiment 1 is that the structure of the elastic heat-insulating support part 1 is different. .

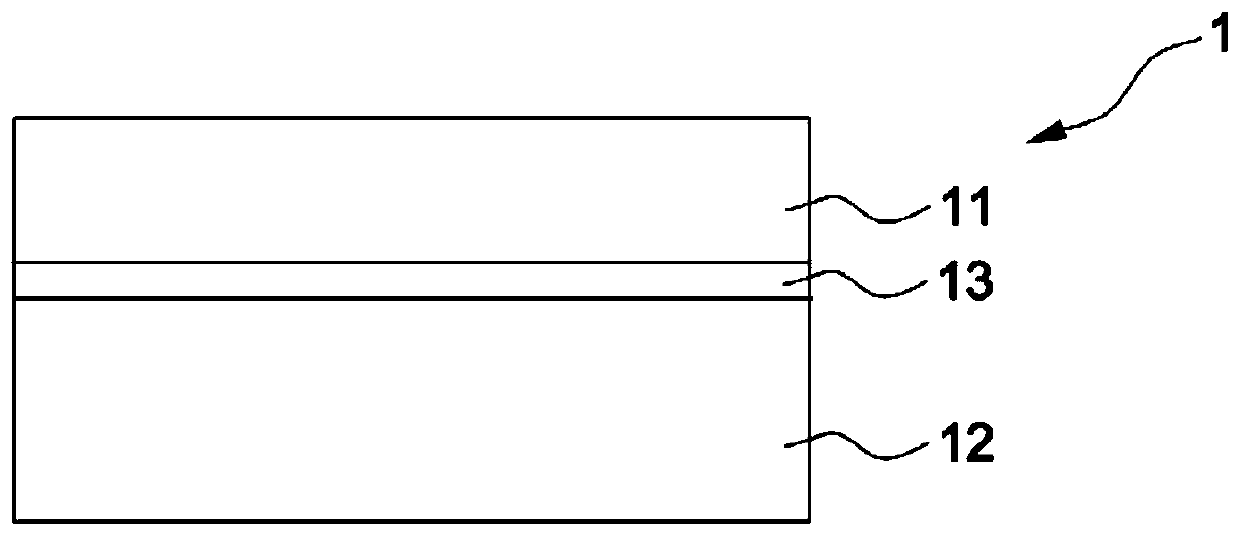

[0050] Specifically, as figure 1 and image 3 As shown, the elastic heat insulation support part 1 includes a soft rubber foam layer 11 and a hard foam layer 12 connected, the soft rubber foam layer 11 and the liquid cold plate 3 are bonded through the first connecting part 2, and the soft rubber foam layer The area of the layer 11 is equal to the area of the liquid cooling plate 3 , which provides a cushioning effect for the liquid cooling plate 3 , and the rigid foam layer 12 is arranged at the bottom of the battery pack box to provide support for the liquid cooling plate 3 .

[0051] Furthermore, the soft rubber foam layer 11 and th...

Embodiment 3

[0056] The third embodiment provides a liquid-cooled plate support and buffer structure 100. The main difference between the liquid-cooled plate support and buffer structure 100 and the liquid-cooled plate support and buffer structure 100 in the above-mentioned embodiment 1 and embodiment 2 is that the elastic heat insulation support Part 1 has a different structure.

[0057] like Figure 4-Figure 12 As shown, in this embodiment, the area of the elastic heat insulating support part 1 is smaller than the area of the liquid cooling plate 3 . The soft rubber foam layer 11 in the elastic heat insulation support part 1 is directly formed on the lower surface of the liquid cooling plate 3, or the soft rubber foam layer 11 is directly formed on the hard foam layer 12, and then installed on the liquid cooling plate 3, or The elastic heat insulation support part 1 includes a bottom film 14 and a soft rubber foam layer 11, the soft rubber foam layer 11 is bonded or formed on the bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compression ratio | aaaaa | aaaaa |

| compression ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com