Tobacco shred structure determining method and device suitable for thin cigarettes

A technology of shredded tobacco structure and determination method, which is applied in the fields of tobacco, application, and tobacco preparation, can solve the problems of low stability between batches, low degree of control of shredded tobacco structure, and great difficulty in finely adjusting the shredded tobacco structure, so as to improve stability , Improve the effect of quality evaluation means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

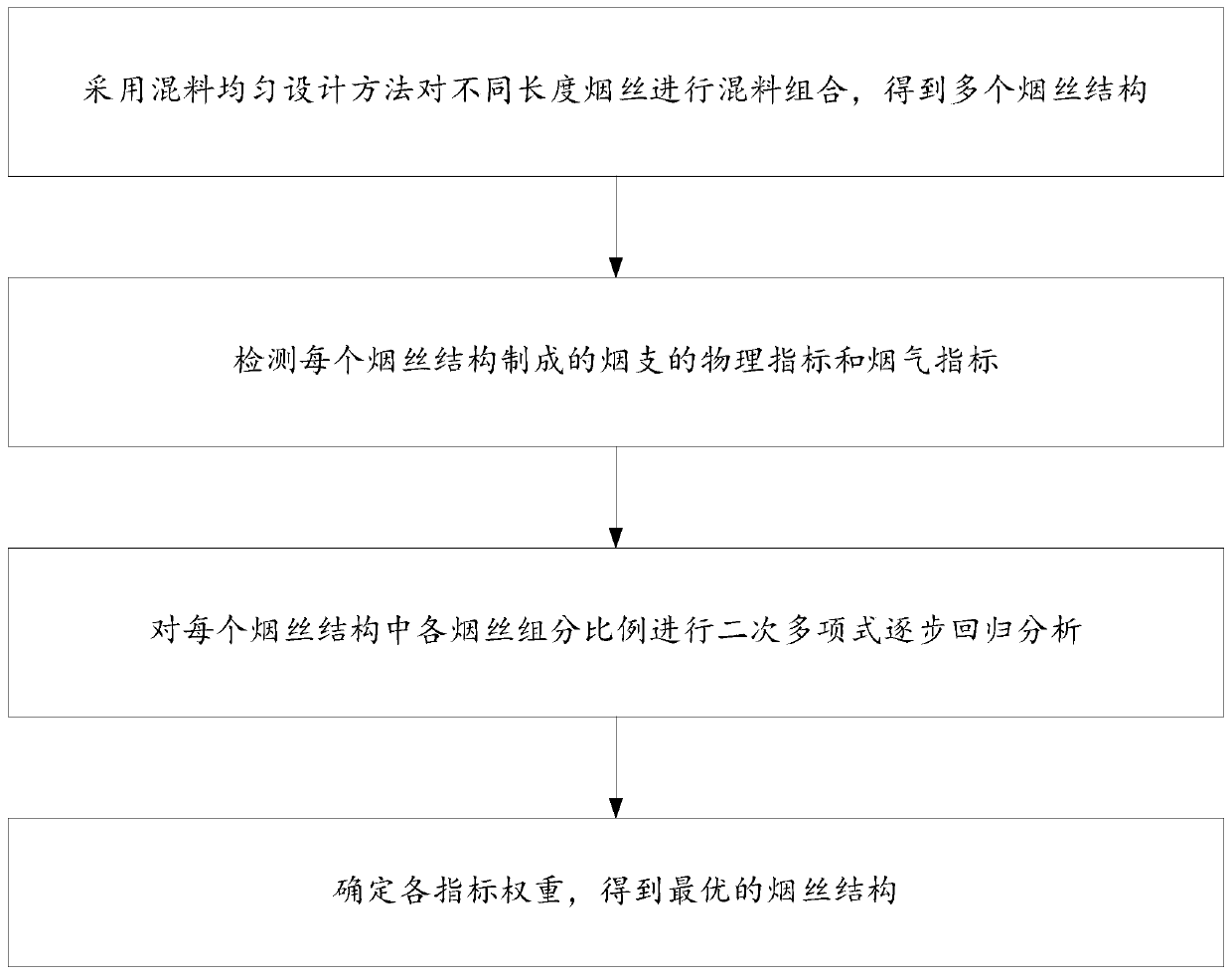

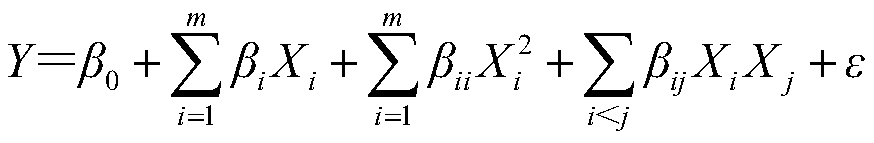

[0030] This example provides a method for determining the structure of shredded tobacco suitable for slim cigarettes, using the method of uniform mixture design and mathematical model analysis to realize the determination of shredded tobacco structure of slim cigarettes, aiming at the physical indicators and smoke indicators of slim cigarettes Comprehensive evaluation of the stability of the product, through the quadratic polynomial stepwise regression solution, optimization to determine the optimal tobacco length combination, that is, the tobacco structure, is very important for stabilizing product quality, ensuring product design quality, and improving process lean management. significance.

[0031] Please refer to the attached figure 1 , the method for determining the shredded tobacco structure suitable for slim cigarettes comprises the following steps:

[0032] S101: Mixing and combining shredded tobacco with different lengths by adopting a uniform mixing design method to...

Embodiment 2

[0074] In order to enable those skilled in the art to better understand the present disclosure, this embodiment provides a specific embodiment, which proposes a method for determining the structure of shredded tobacco, the method comprising the following steps:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com