Heat isolation organ protection cover

A protective cover and organ technology, applied in the direction of additive processing, etc., to achieve the effect of reducing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

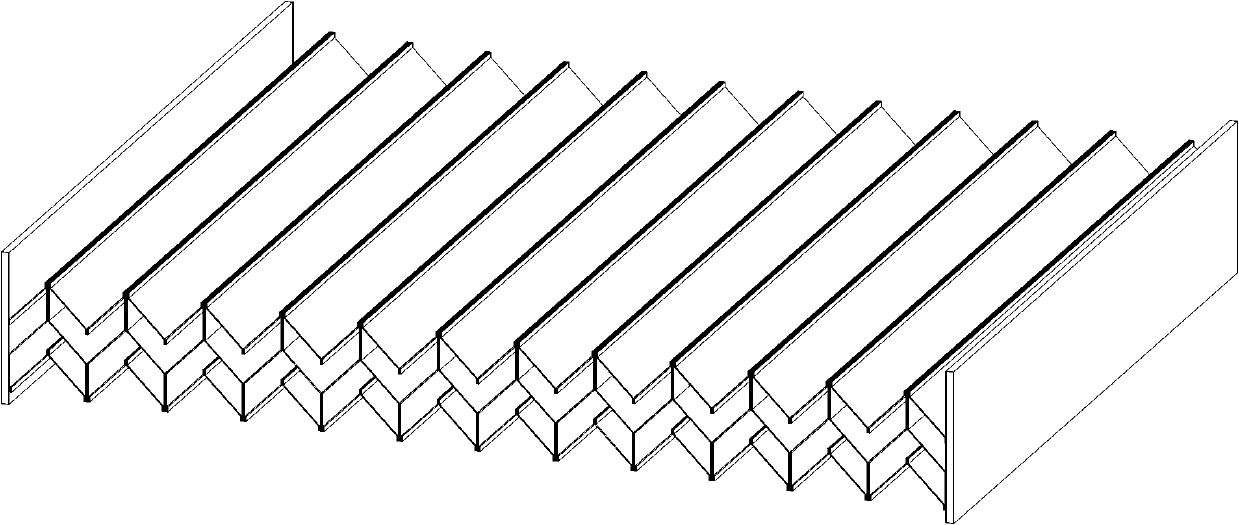

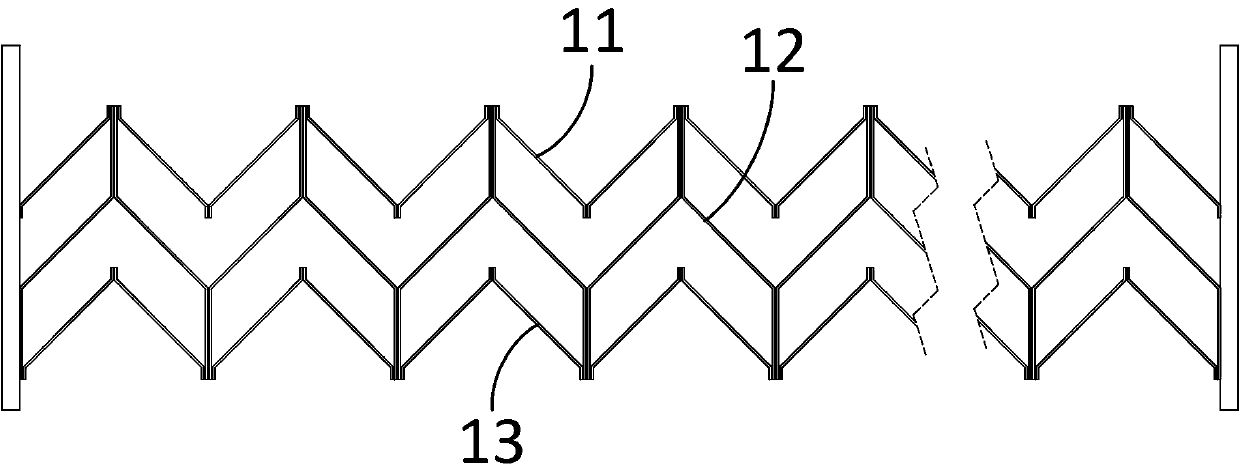

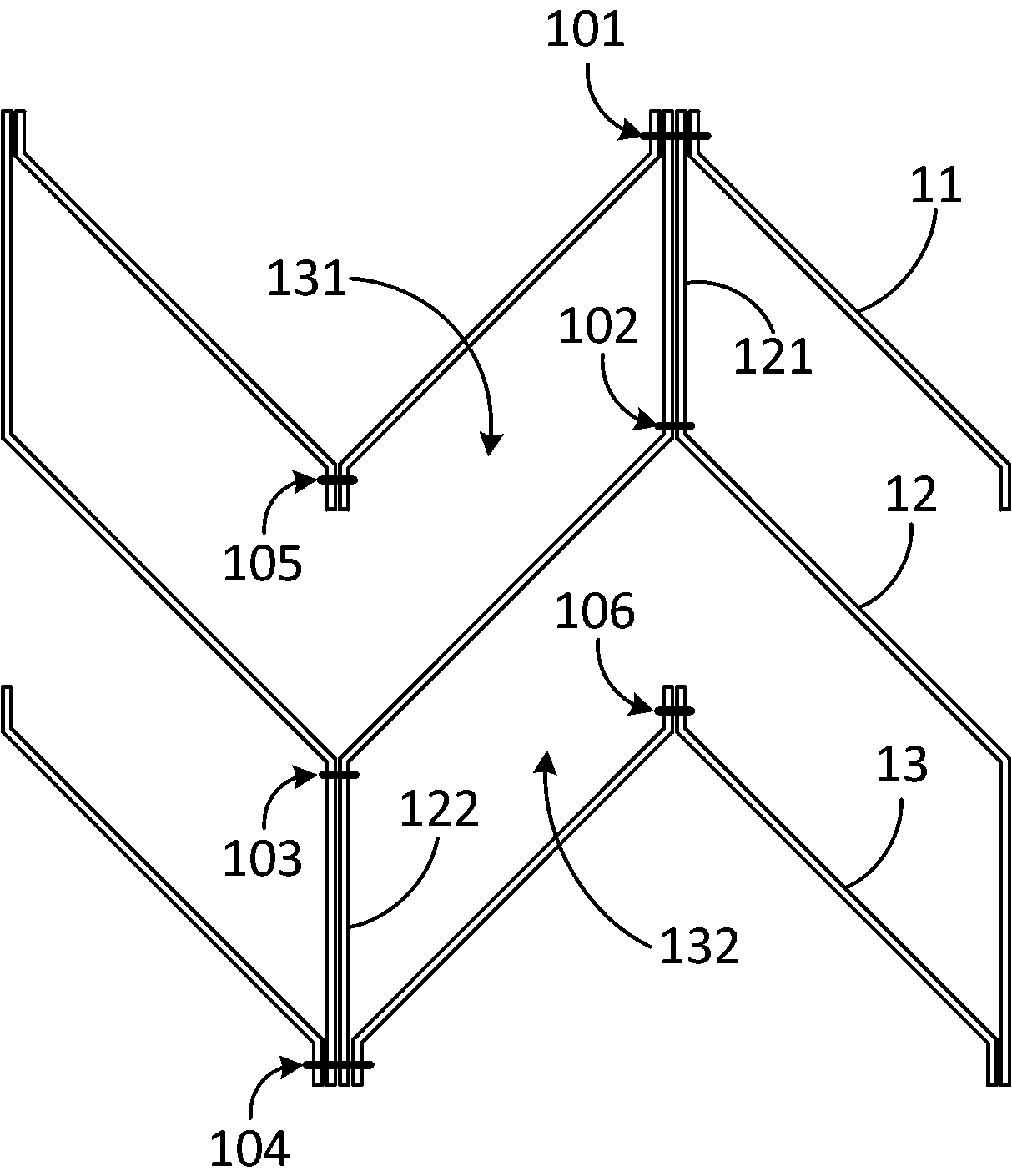

[0023] Such as figure 1 with figure 2 As shown, in this embodiment, the protective cover of the heat-insulating organ comprises three layers of wave-shaped heat-insulating layers, which are respectively the first heat-insulating layer 11 , the second heat-insulating layer 12 and the third heat-insulating layer 13 . Such as image 3 As shown, the first heat insulation layer 11 is stitched and connected at the first seam point 101 and the fifth seam point 105 using high-temperature thread to form a wave-shaped structure, the first seam point 101 is its crest, and the fifth seam point 105 is its crest. at the trough. Similarly, the second heat insulation layer 12 is stitched and connected at the second seam point 102 and the third seam point 103 to form a wave-shaped structure of the second heat insulation layer; the third heat insulation layer 13 is connected at the fourth seam point 104 and the The six seaming points 106 are seamed and connected to form the wavy structure o...

Embodiment 2

[0029] Such as Figure 5 with Image 6 As shown, in this embodiment, the heat-insulating organ protective cover includes four layers of corrugated heat-insulating layers, which are respectively the first heat-insulating layer 21, the second heat-insulating layer 22, the third heat-insulating layer 23 and the fourth heat-insulating layer twenty four. Such as Figure 7 As shown, the first heat insulation layer 21 is stitched and connected at the first seam point 201 and the seventh seam point 207 using high-temperature thread to form a wave-shaped structure, the first seam point 201 is its crest, and the seventh seam point 207 is its peak. at the trough. Similarly, the second heat insulation layer 22 is seamed and connected at the second seam point 202 and the third seam point 203, the third heat insulation layer 23 is seamed and connected at the fourth seam point 204 and the fifth seam point 205, and the fourth heat insulation layer The thermal layer 24 is stitched and conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com