High-efficient spirit distillation method

A high-efficiency wine steaming and wine steaming machine technology is applied in the field of liquor distillation, which can solve the problems of raw material waste and wine quality decline, and achieve the effect of avoiding the decline in the quality of distilled wine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below by means of specific embodiments:

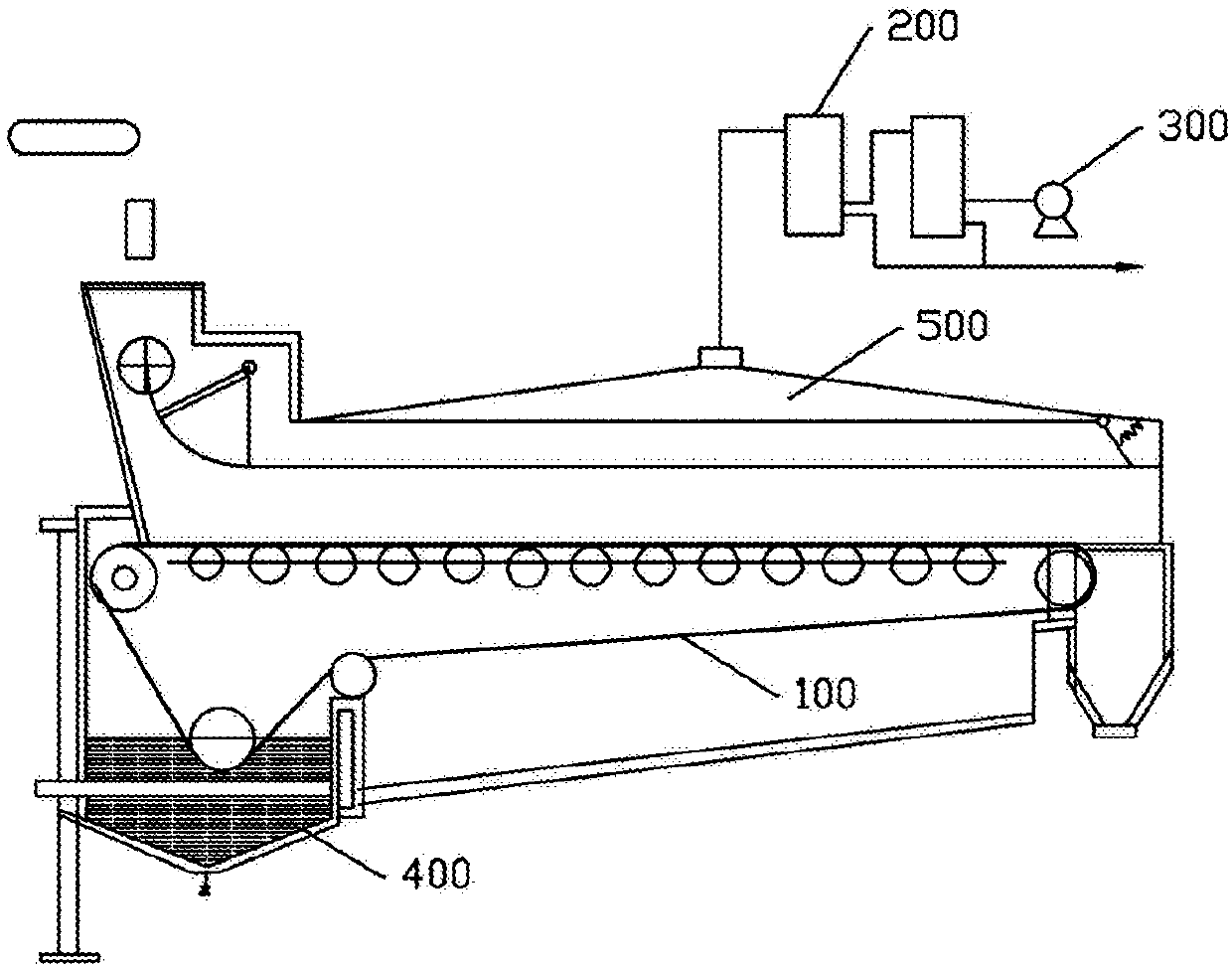

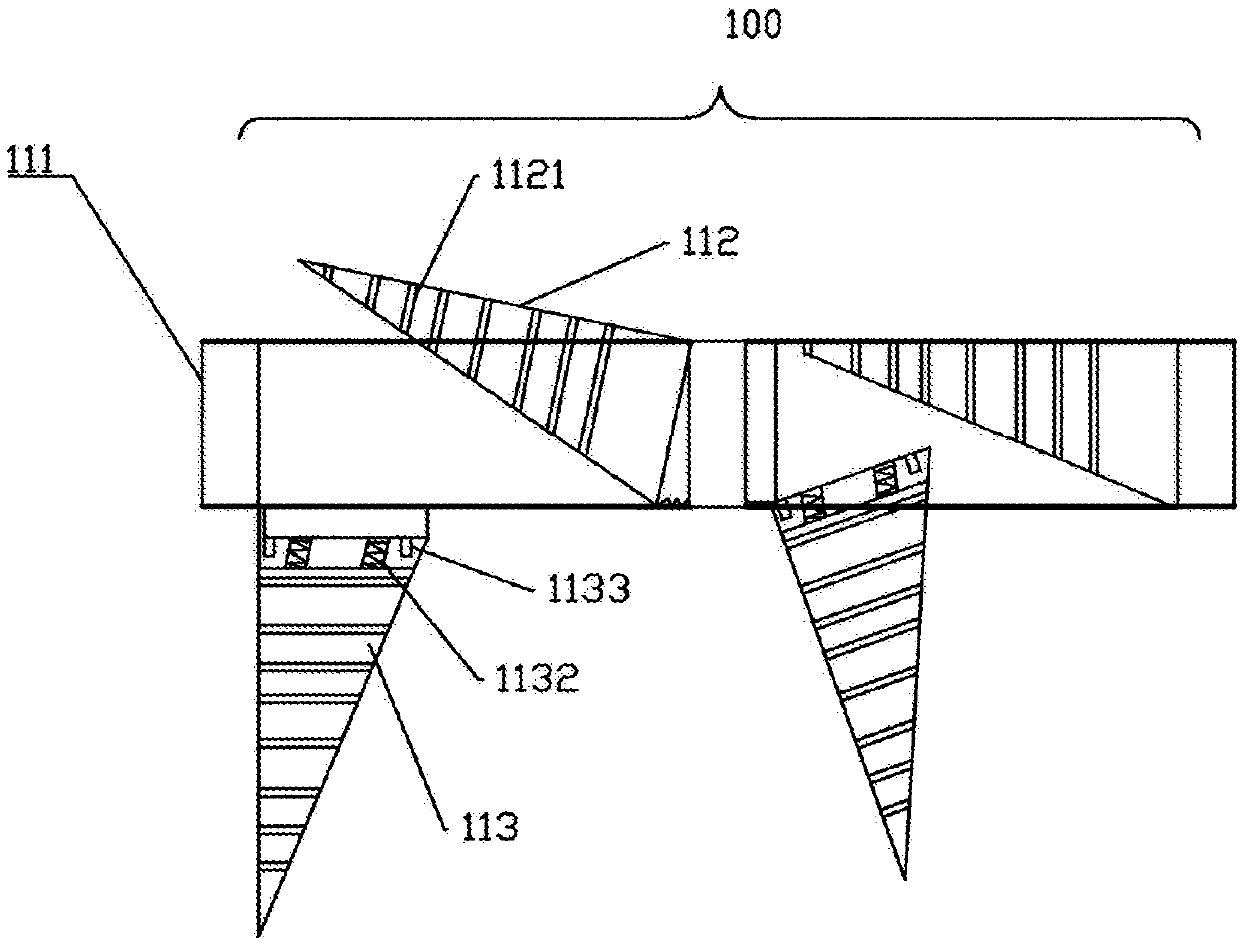

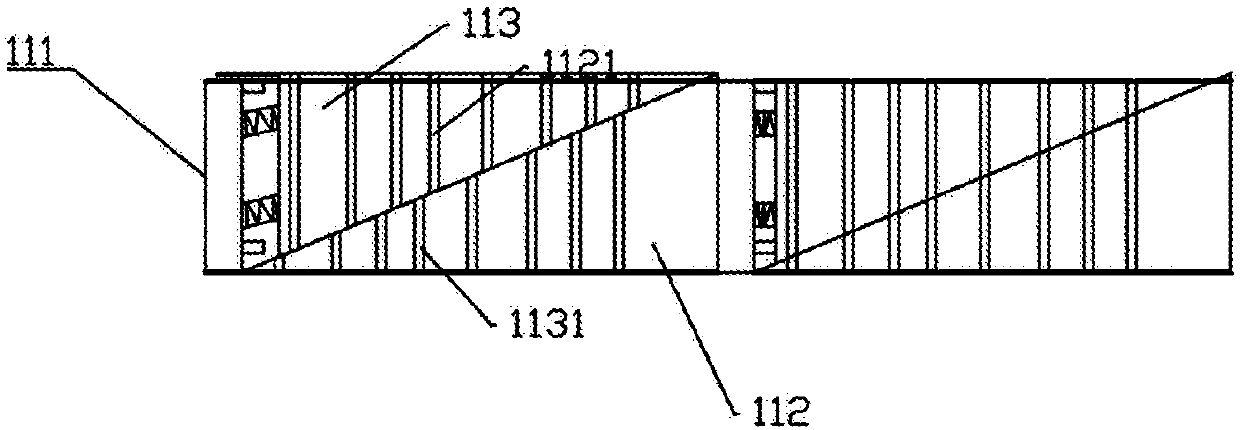

[0037] The reference numerals in the accompanying drawings of the description include: transmission chain 100, transmission block 110, fixed frame 111, base block 112, elastic block 113, first ventilation through hole 1121, second ventilation through hole 1131, compression spring 1132, limiting Position column 1133, condenser 200, air pump 300, steam layer 400, wine gas layer 500.

[0038] High-efficiency wine steaming method, adopting automatic wine steaming machine to implement the method, such as figure 1 , figure 2 as well as image 3 The shown automatic wine steaming machine includes a wine steaming mechanism, a condenser 200 and an air pump 300. The wine steaming mechanism includes a housing and a steam layer 400, a transmission layer and a wine gas layer 500 arranged in the housing. The transmission layer includes a conveyor chain 100 , the thinning wheel and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com