Method and structure for reinforcing prefabricated prestressed beam-column joint through mixed fiber concrete

A technology for concrete reinforcement and beam-column joints, which is used in building maintenance, building construction, construction, etc. to achieve the effects of improving strength and bearing capacity, low engineering cost, and preventing danger.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

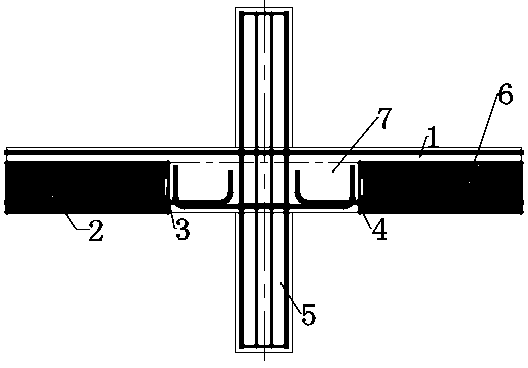

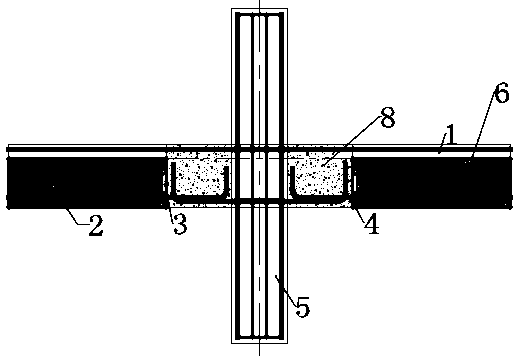

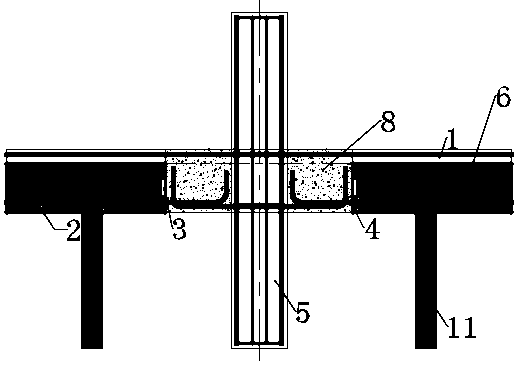

[0033] refer to Figure 1 to Figure 10

[0034] A method for reinforcing prefabricated prestressed beam-column joints with mixed fiber concrete, comprising the following steps:

[0035] (1) Use steel pipe brackets to support the undamaged beam bottoms on both sides of the cast-in-place columns of prefabricated prestressed beam-column joints, such as image 3 shown;

[0036] (2) Use a drilling machine to grind the diagonal area of the concrete in the damaged area of the plastic hinge at the beam end, such as Figure 4 shown;

[0037] (3) Set shear keys at the intact beam end section area and the core area section, and do a chisel treatment at both ends of the shear key. The shear key is as follows: Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com