Acid fracturing and water controlling integrated device, acid fracturing and water controlling tubular column and acid fracturing and water controlling method

A water control pipe and acid fracturing technology, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of not considering flow regulation and water control, difficulty in cementing, and difficult realization of coiled tubing drilling ball seat removal, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

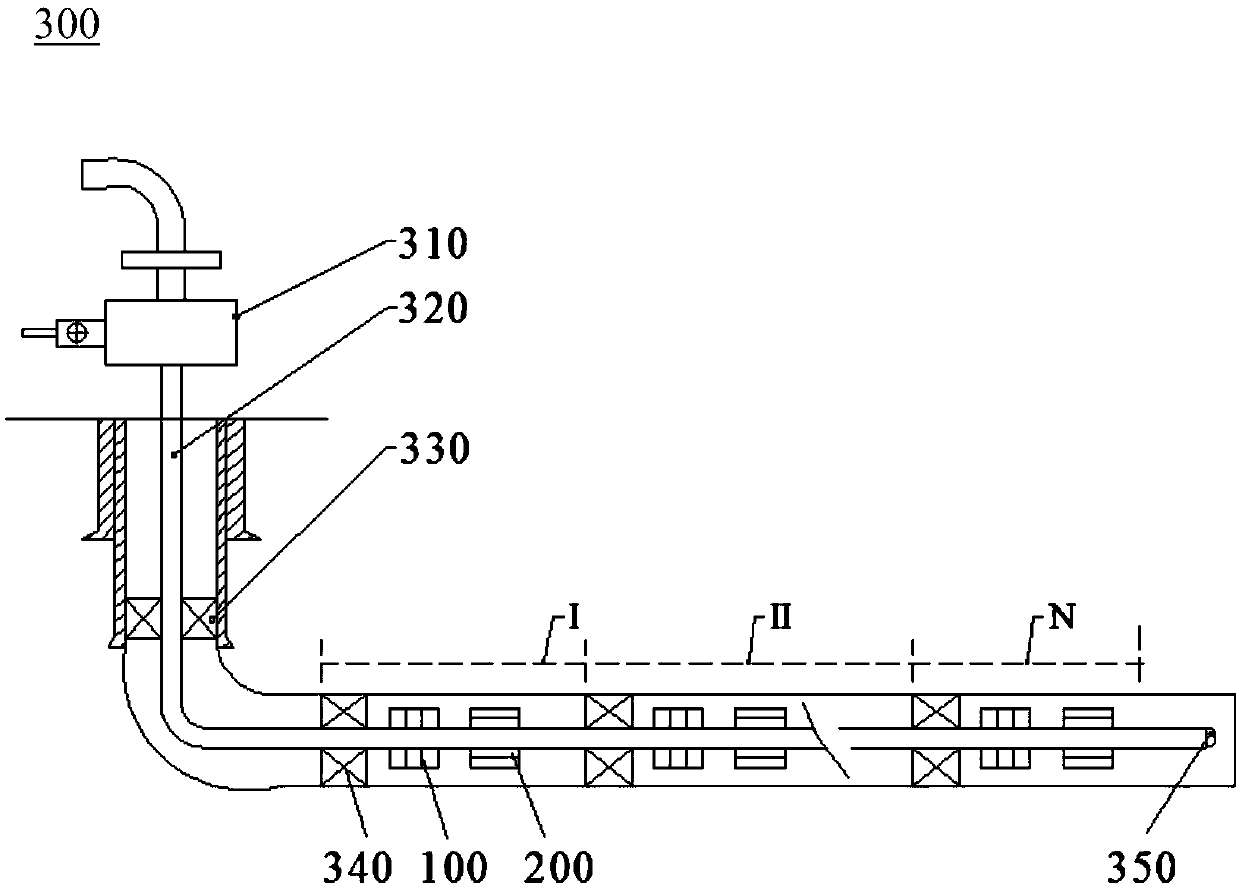

[0026] The present invention is introduced below by accompanying drawing.

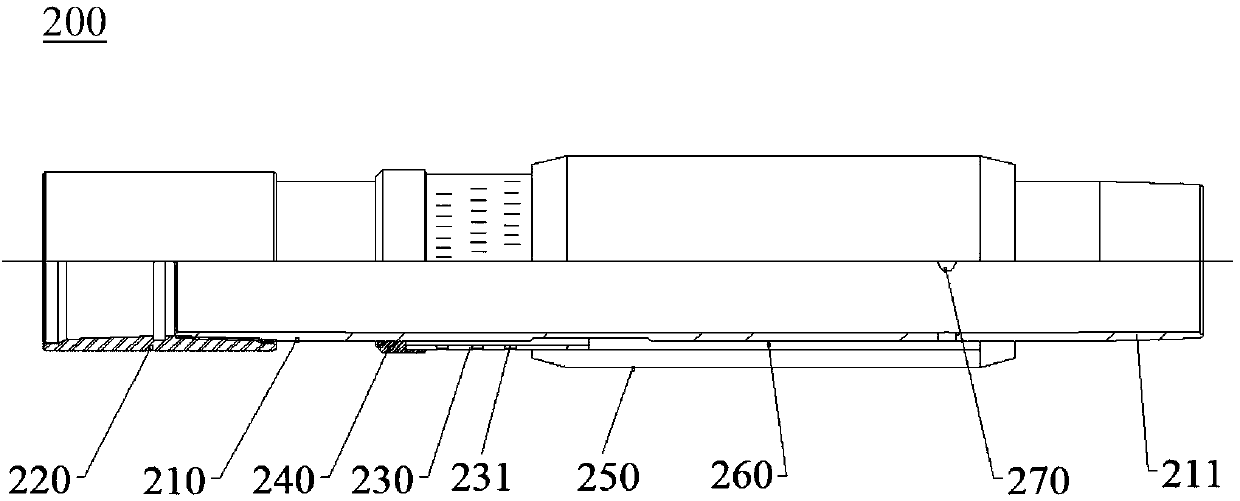

[0027] The integrated device 300 for acid fracturing and water control according to the present invention includes an acid fracturing unit 100 for acid fracturing construction and a water control nipple 200 for unidirectional flow control and water control.

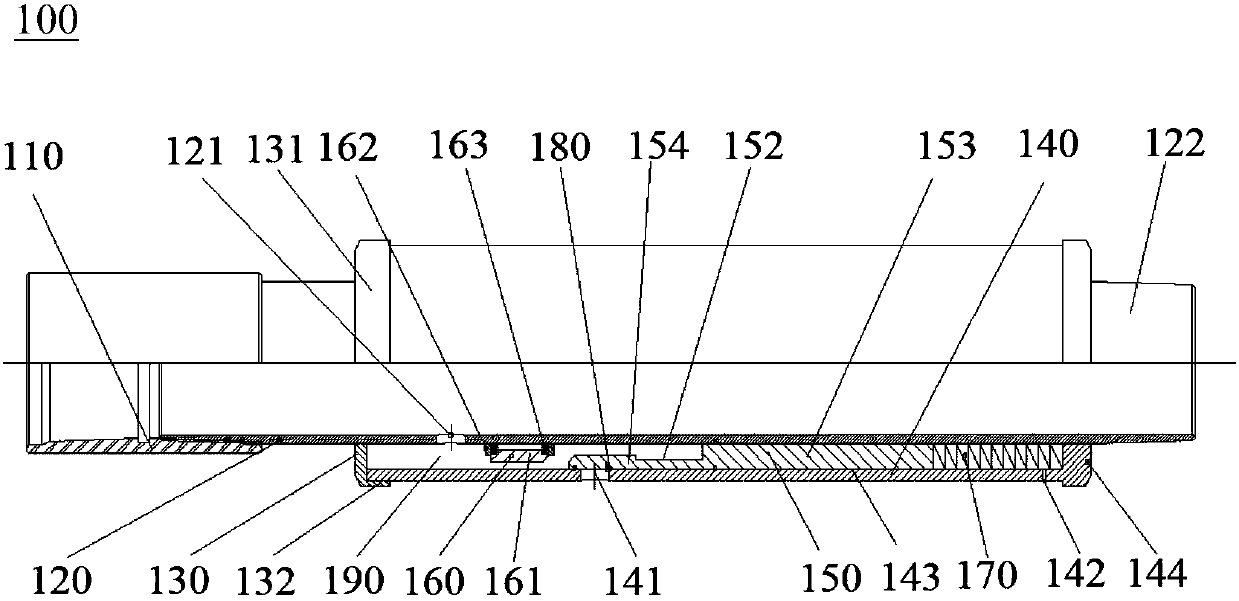

[0028] figure 1 The structure of the acid fracturing unit 100 of the acid fracturing water control integrated device 300 according to the present invention is shown. Such as figure 1 As shown, the acid fracturing unit 100 includes an acid fracturing base pipe 120 as the main body of the acid fracturing unit 100 . The acid-pressed base pipe 120 is arranged in a cylindrical structure, and a channel for fluid circulation is provided inside the acid-pressed base pipe 120 . At the front end of acid pressing base pipe 120 ( figure 1 The left end of the base pipe) is connected with a base pipe box joint 110, and the box joint 110 is used to connect o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com